Spliced directional backlight source and display system using same

A display system and backlight technology, applied in the direction of nonlinear optics, optics, optical components, etc., can solve the problems of depth limitation, viewing angle limitation, etc., achieve the effect of expanding viewing angle, eliminating dark areas, and realizing adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

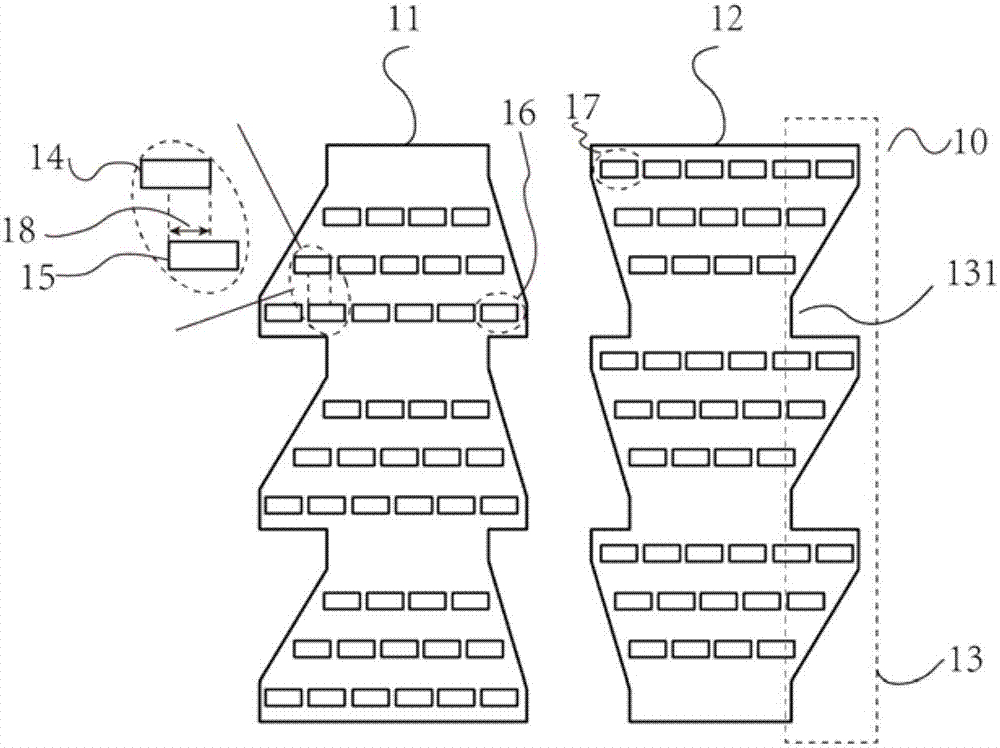

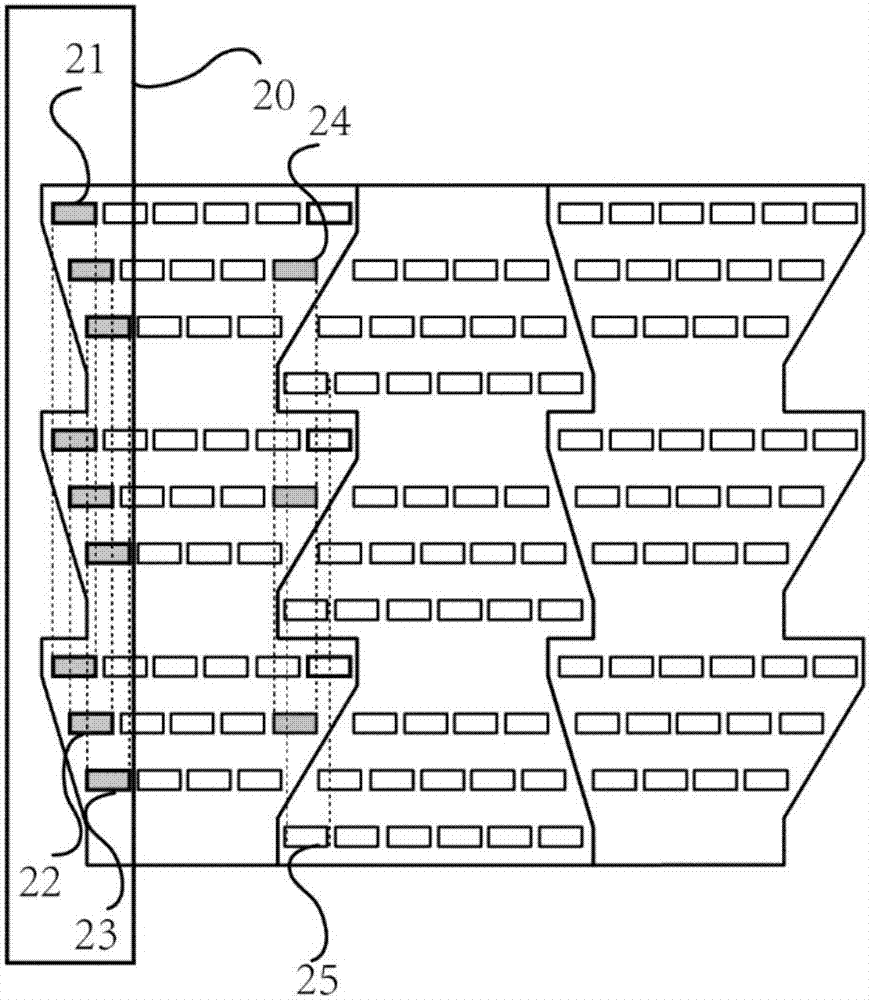

[0041] like figure 1The structure of a spliced directional backlight shown in -4 mainly includes: a plurality of spliced substrates 10 , several light-emitting areas and a light-diffusing film layer 30 .

[0042] Splicing structures 13 are provided on both sides of the splicing substrate 10 , and the splicing structures 13 are used for splicing and extending the splicing substrates 10 . The splicing structure 13 is a gap 131 arranged at intervals on both sides of the splicing substrate 10, and complementary splicing is completed between the splicing substrates 10 through the gap 131, and the gap 131 can be set in a triangle, rectangle, trapezoid, polygon or any of the circles.

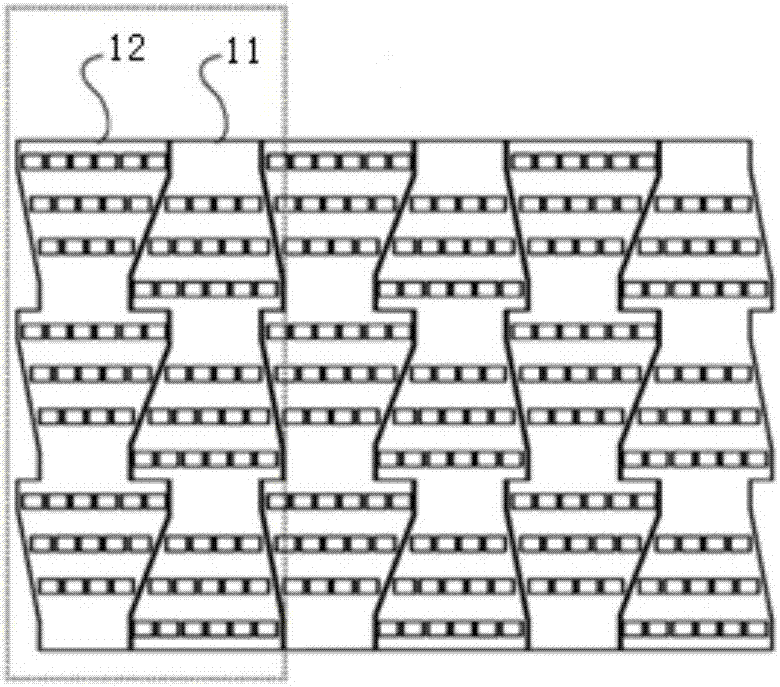

[0043] Preferably, the splicing structure 13 is arranged in a triangular zigzag shape, the splicing substrate 10 includes a first substrate 11 and a second substrate 12, the left side of the first substrate 11 and the left side of the second substrate 12 The right side can be complementary connec...

Embodiment 2

[0050] The similarities with the above-mentioned solutions will not be described in detail. As another preferred specific implementation mode, in this embodiment, the arc-shaped splicing type directional backlight and the Figure 5b In the naked-eye 3D display system 50 equipped with an arc splicing type directional backlight as shown, the splicing substrates 10 are spliced with each other to form an arc, and the light-emitting area is arranged inside the arc; the arc splicing type The directional backlight 51 is alternately spliced by several first substrates 11 and second substrates 12 into an arc with a certain radian and radius of curvature, and a light diffusion film layer 30 is placed a certain distance in front of the light-emitting area. Therefore, through the first substrate 11 and the For the splicing of the second substrate 12, the light-emitting areas are continuously and staggered along the lateral direction; the light diffusion film layer 30 is arranged in fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com