Electronic atomization device and atomization core thereof

An electronic atomizing device and atomizing core technology, applied in the direction of tobacco, can solve the problems of low heat and mass transfer efficiency of the atomizing core, explosive liquid, etc., and achieve strong heat and mass transfer driving force, steep gradient drop, Improve the effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

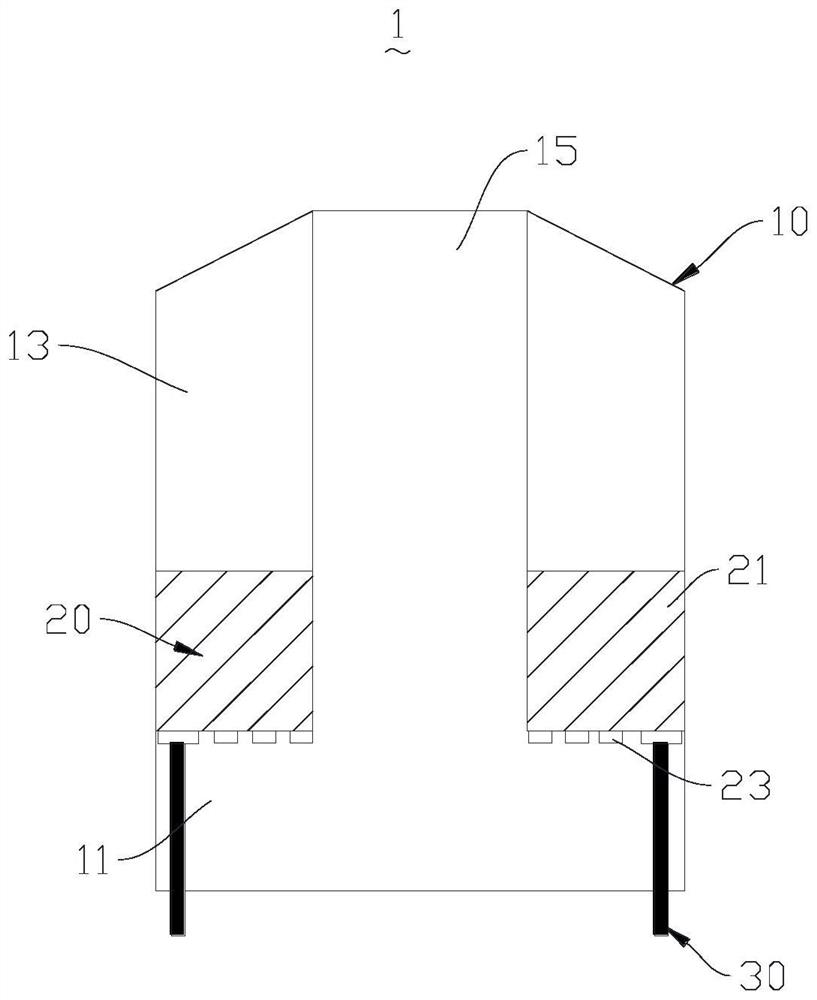

[0034] figure 1 and figure 2 The electronic atomization device 1 in some embodiments of the present invention is shown, and the electronic atomization device 1 can be used to heat and atomize the liquid and aerosols to generate a substrate, which can be inhaled by the user, which can be in the shape of a flat column in some embodiments. , for easy holding. The electronic atomizing device 1 includes a housing 10 , an atomizing core 20 and a pair of electrodes 30 in some embodiments. The housing 10 is used to form an atomizing chamber 11 , a liquid storage chamber 13 and an air outlet channel 15 . The atomizing core 20 is arranged in the casing 10 and is used for heating and atomizing the liquid aerosol to generate the substrate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com