Combustion smoking and heating dual-purpose cigarette

A dual-use technology for cigarettes, which is applied in the field of dual-purpose cigarettes for burning, smoking and heating, and can solve the problems that cigarettes cannot be used together and the application environment is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

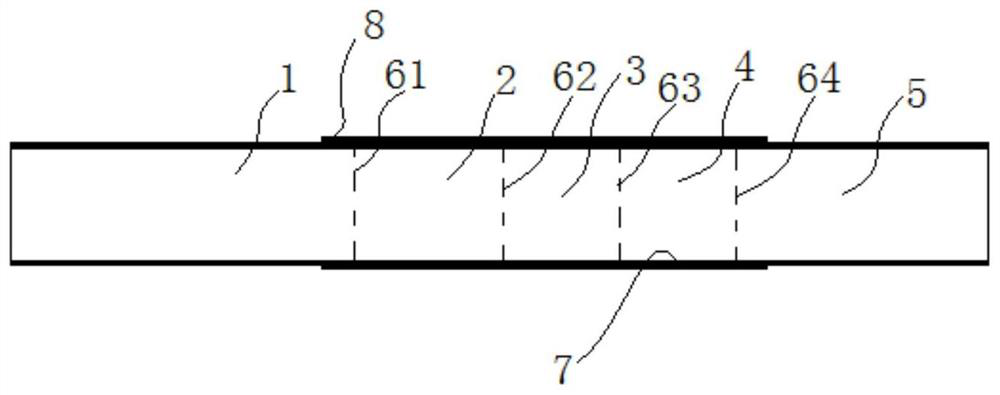

Embodiment 1

[0042] A dual-purpose cigarette, the dual-purpose type means that the cigarette is suitable for both ignited smoking and heat-not-burn smoking, which includes thin segments, support segments, cooling segments, filter rod segments, and cut tobacco segments connected in sequence. , the tearing position is formed by indentation or pressure feeding on the cigarette. The support section, the cooling section and the filter section are wrapped by forming paper to form a filter rod section, the thin section and the cut tobacco section are assembled on both ends of the filter rod section, and the cigarettes are formed by wrapping the tipping paper.

[0043] The suction resistance of the cut tobacco segment is controlled at (500±60)Pa, the length is (45±0.5)mm, the circumference is (23.4±0.3)mm, and the filling density of the cut tobacco is 238mg / cm 3 .

[0044] The length of the thin segment is (15±0.5) mm, the circumference is (23.4±0.3) mm, the suction resistance of the thin segment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Draw resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com