Docking device and folding precision adjusting method

A technology of docking device and adjustment method, which is applied to ships and other directions, and can solve problems such as difficult installation, deformation, and uncontrollable docking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

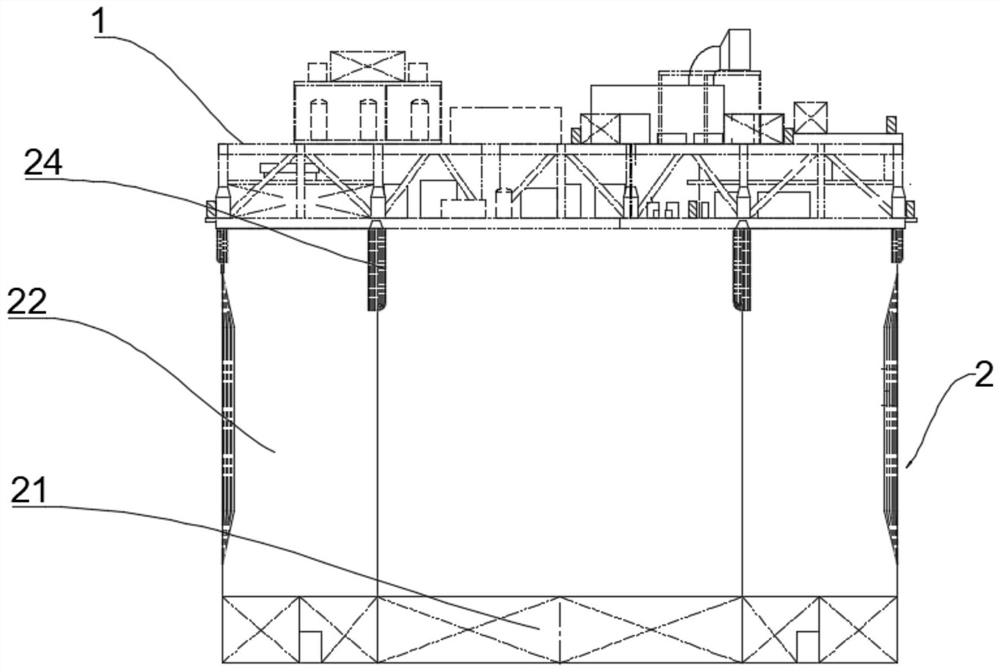

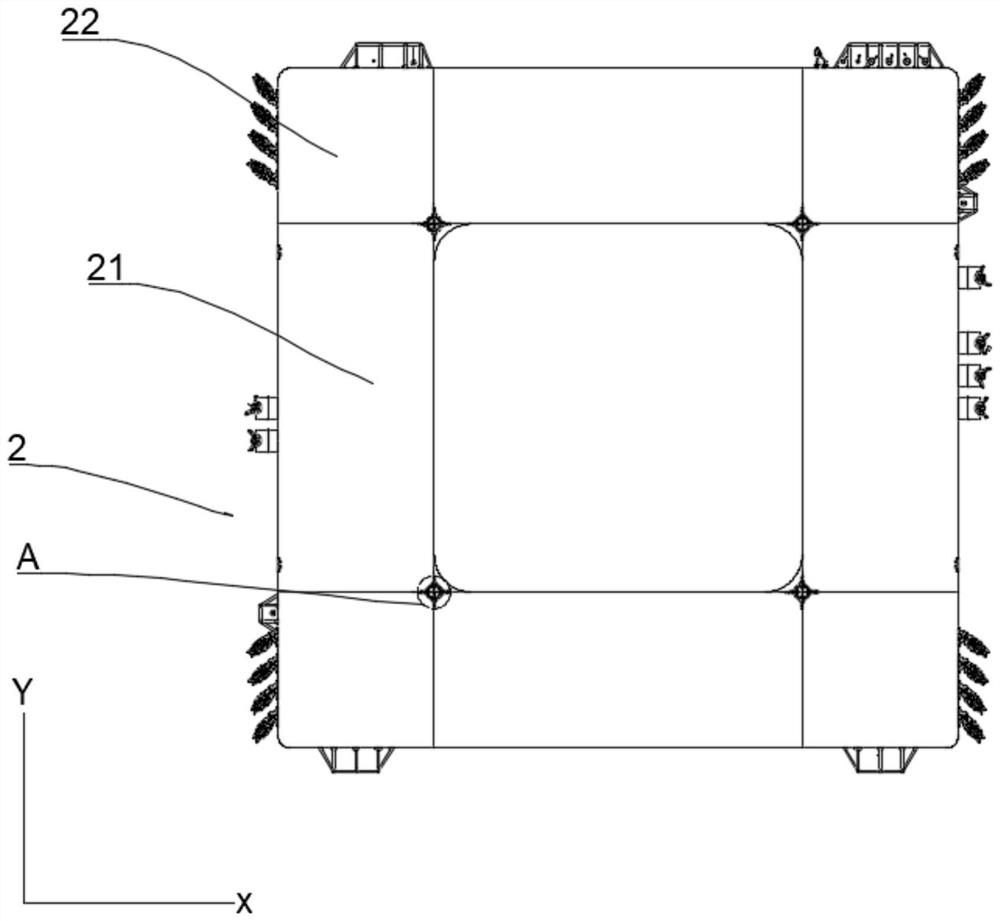

[0046] see figure 1 and figure 2 , the floating production platform provided in this embodiment includes an upper hull 1 , a lower hull 2 and a docking device 3 . Among them, the upper hull 1 is a truss structure, the lower hull 2 includes an annular buoy 21 and a plurality of columns 22 fixed on the buoy 21. When the upper hull 1 and the lower hull 2 are joined together to form a floating production platform, the upper hull 1 and the The column 22 is connected.

[0047] The buoy 21 floats on the water surface and is the foundation of the entire platform. The interior of the buoy 21 is hollow and can be provided with multiple functional cabins and channels. Looking down, the buoy 21 may be a circular shape, a zigzag shape, etc. In this embodiment, the buoy 21 is a square, and the four sides of the buoy 21 are of equal width. When a plurality of uprights 22 are arranged on the buoy 21, they are arranged at intervals along the edge direction of the buoy 21, and the num...

Embodiment 2

[0066] see Figure 4 , Image 6 and Figure 7 , the second embodiment of the present disclosure provides a method for adjusting the folding precision, which includes the following steps:

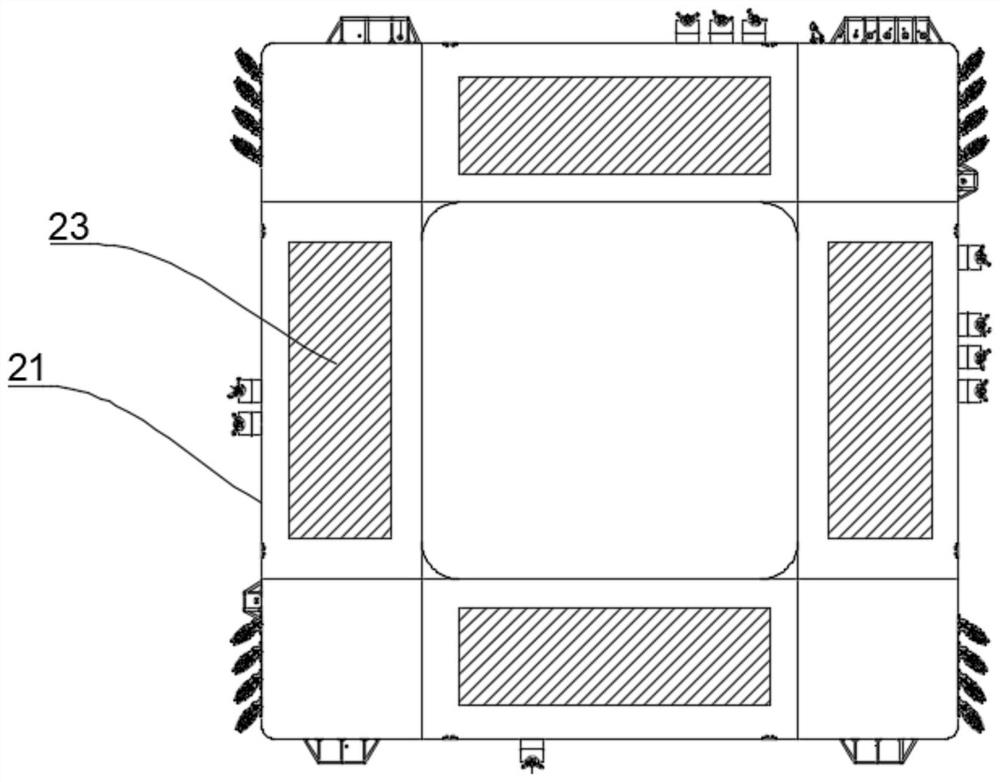

[0067] S1. Move the lower hull 2 to the water surface below the upper hull 1 to make the orientation of the lower hull 2 and the upper hull 1 consistent, and adjust the deformation of the lower hull 2 by adjusting the filling amount of the medium in the ballast tank 23 on the lower hull 2 To the allowable range of deviation, complete the preliminary alignment of the lower hull 2 and the upper hull 1;

[0068] S2. Gradually lower the upper hull 1, and complete the closing through the docking device 3.

[0069] It should be noted that, in the above step S1, after the upper hull 1 is launched, the barge can be towed to the bottom of the crane 4 in the dock, and the upper hull 1 is lifted into the air by the crane 4, and the lifting height should be at least higher than that after the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap