Earphone rubber-coating forming mould structure

A forming mold and rubber encapsulation technology, which is applied to household appliances, other household appliances, sensors, etc., can solve the problems of difficult control, inconvenient operability, long development cycle, etc., to achieve improved accuracy, simple structure, and prevent glue overflow problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

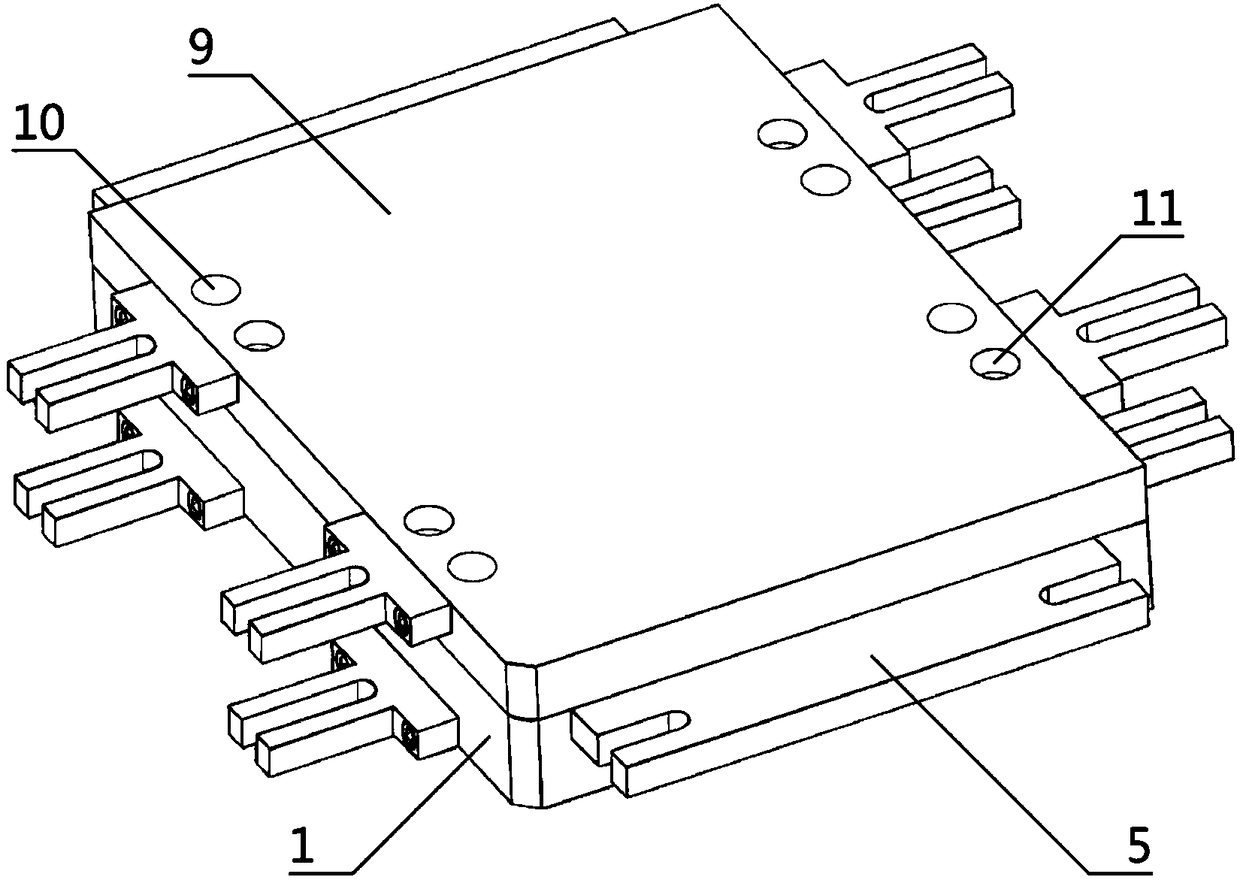

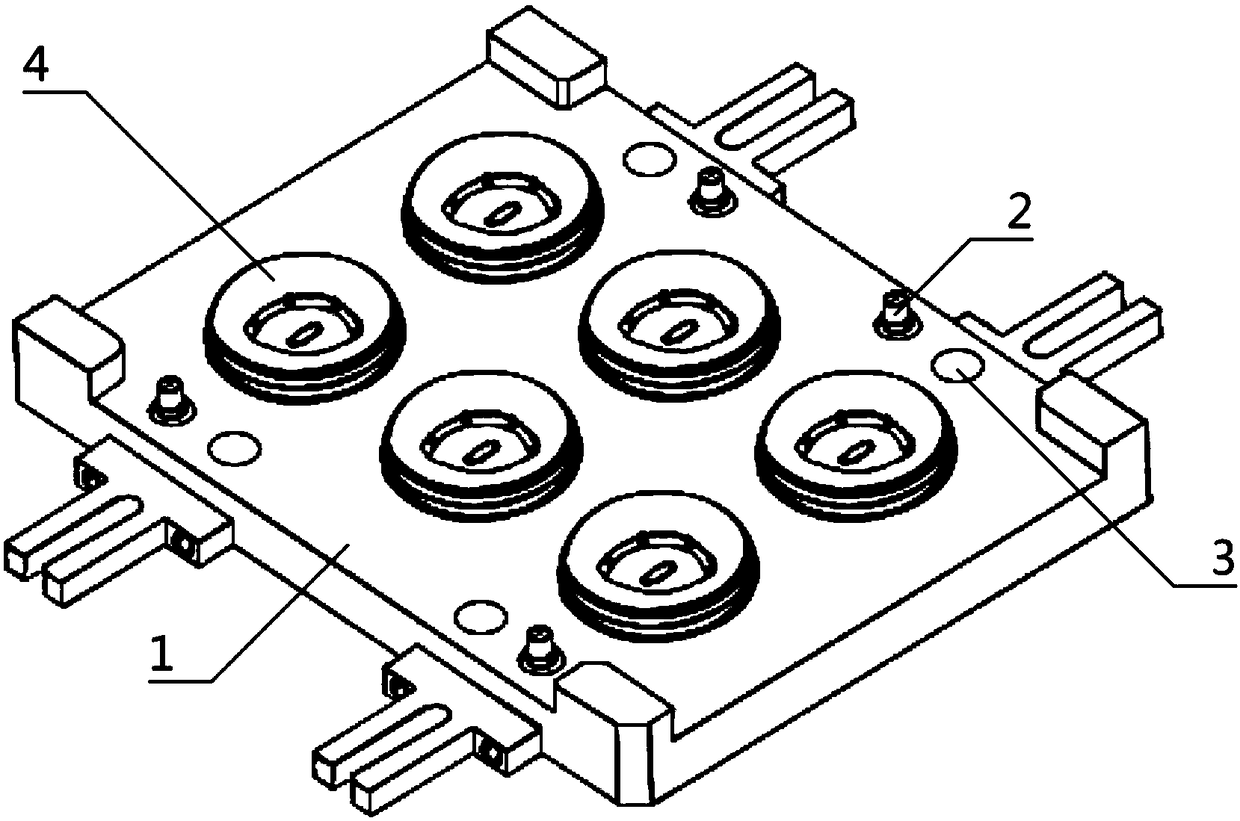

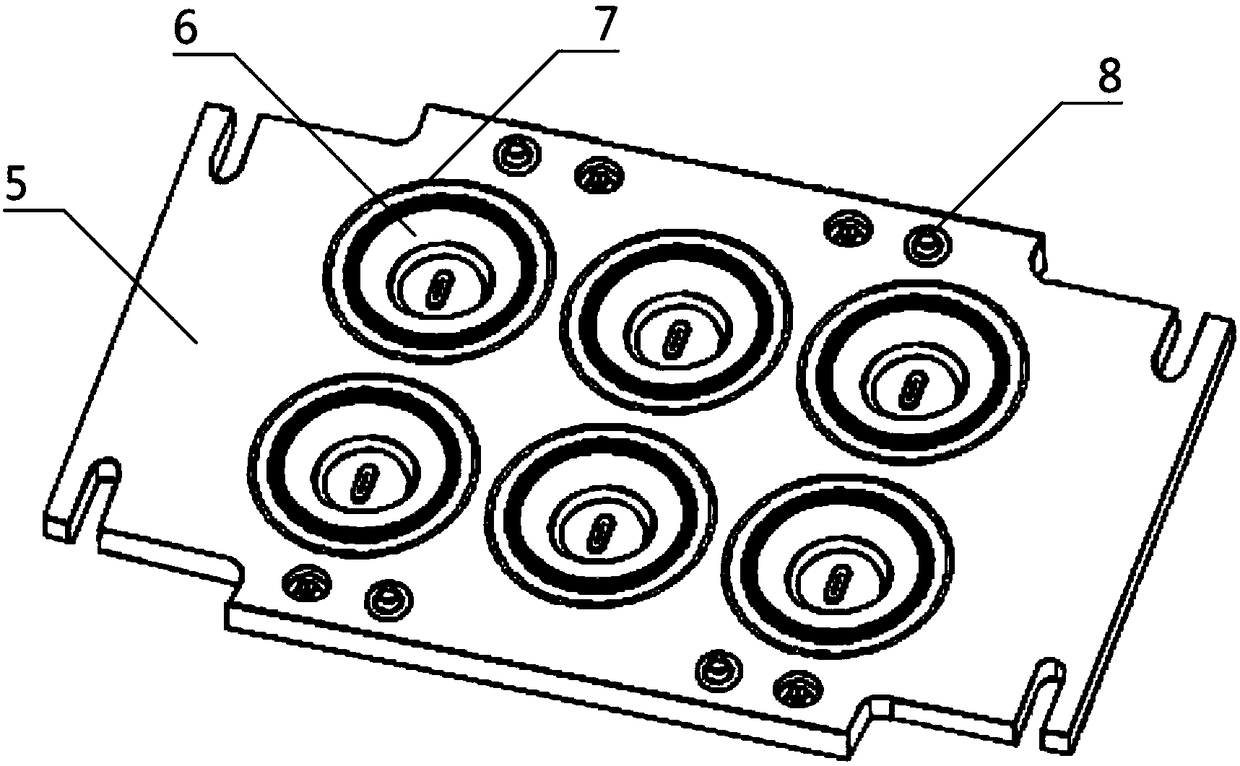

[0026] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 An earphone overmolding mold structure is shown, which is characterized in that it consists of a lower template 1, a middle template 5 and an upper template 9, and the lower template 1 is also provided with several lower mold positioning columns 2 and several lower molds Positioning holes 3 and several lower mold molding dies 4, any of the lower mold positioning columns 2 are located in the middle of the lower template 1, the lower mold positioning columns 2 are fixedly connected with the lower template 1, and any of the lower mold positioning holes 3 Located on one side of the lower mold positioning column 2, the lower mold positioning hole 3 is fixedly connected to the lower template 1, any of the lower mold forming molds 4 is located in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com