Handling method of changing attributes of manufacturing processes for semi-conductor equipment

A manufacturing process and semiconductor technology, applied in semiconductor/solid-state device manufacturing, memory systems, electrical digital data processing, etc., can solve problems such as inability to distinguish whether the attributes of the equipment manufacturing process have changed, polluting products, and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

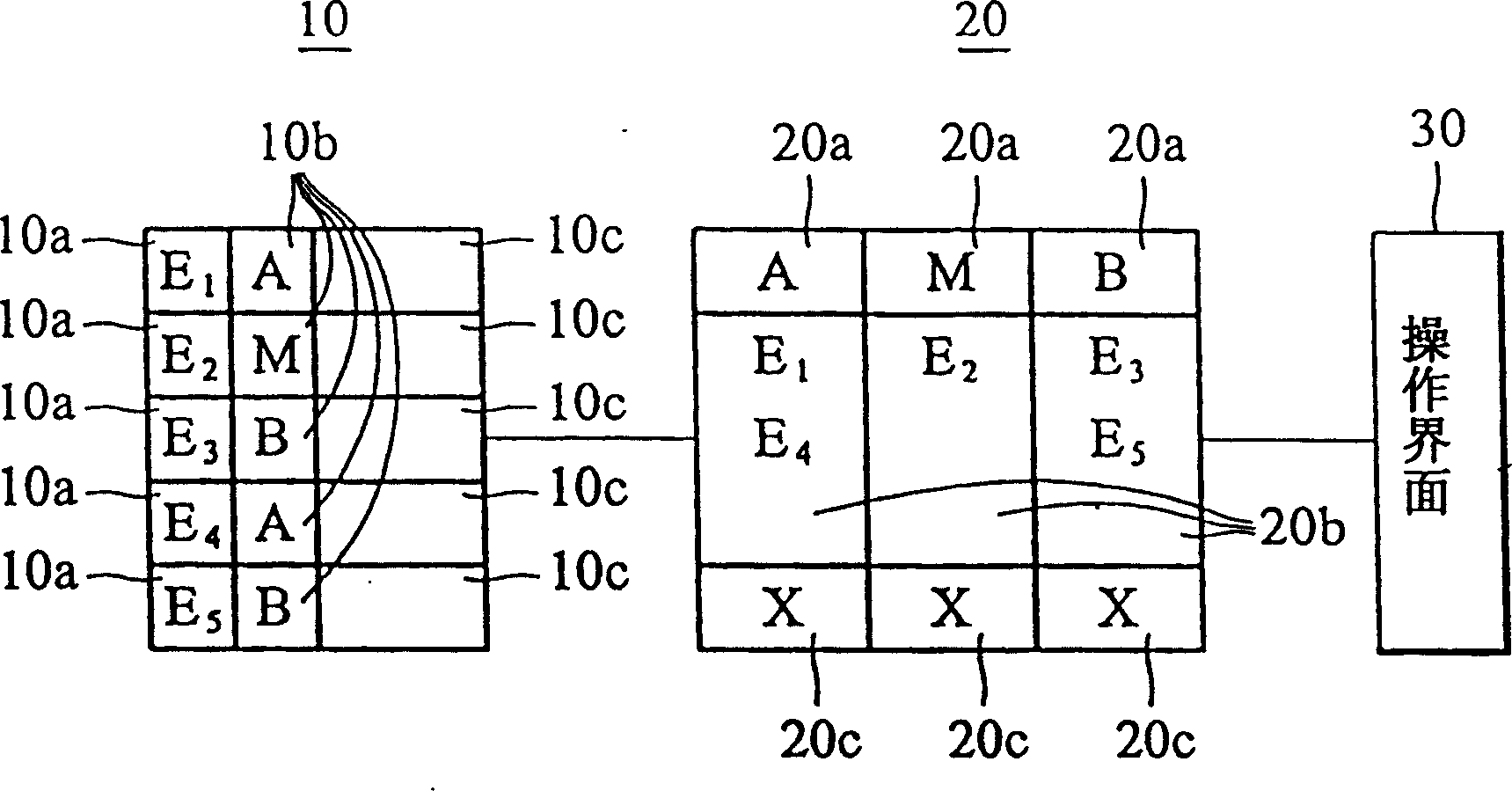

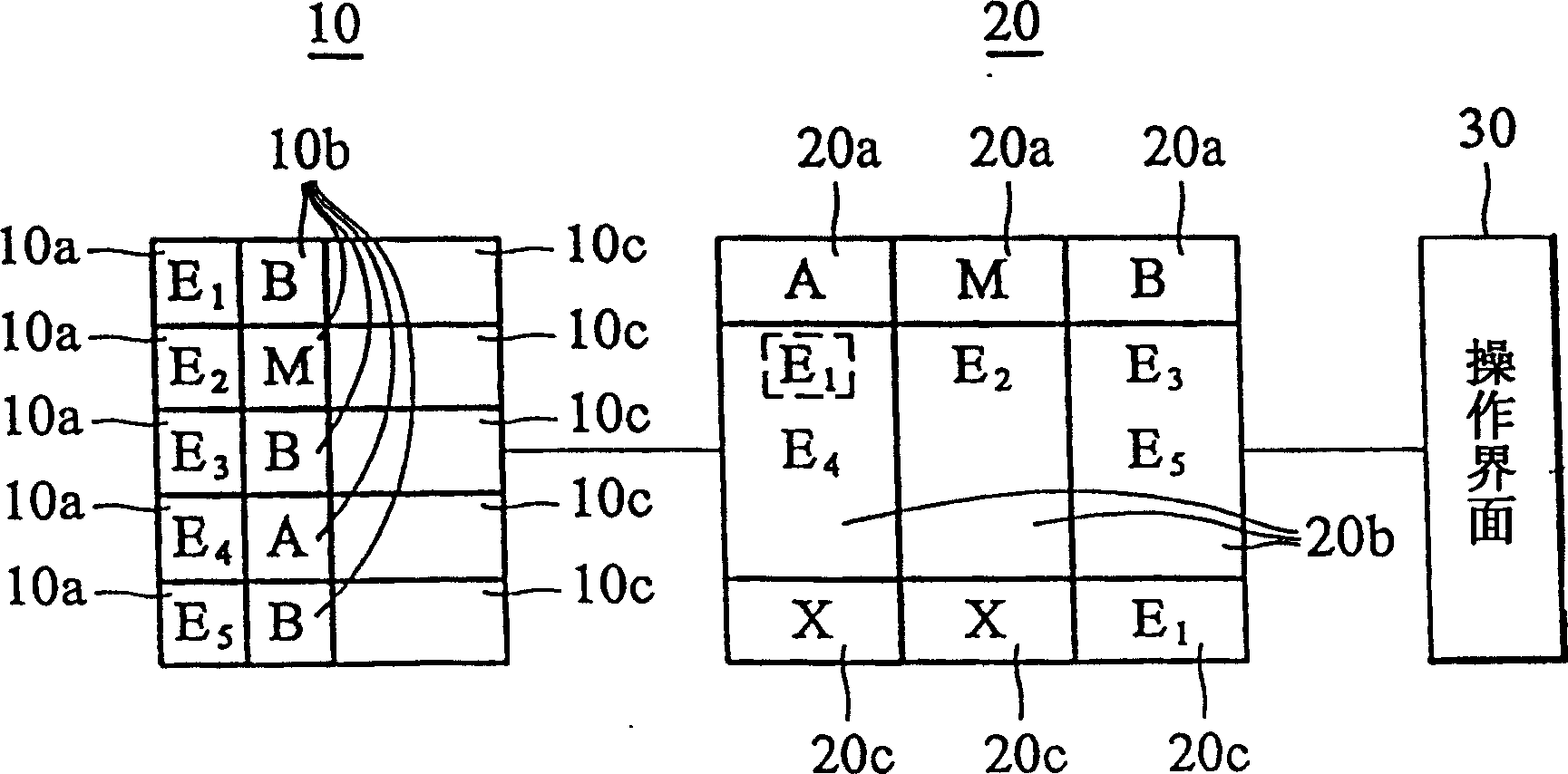

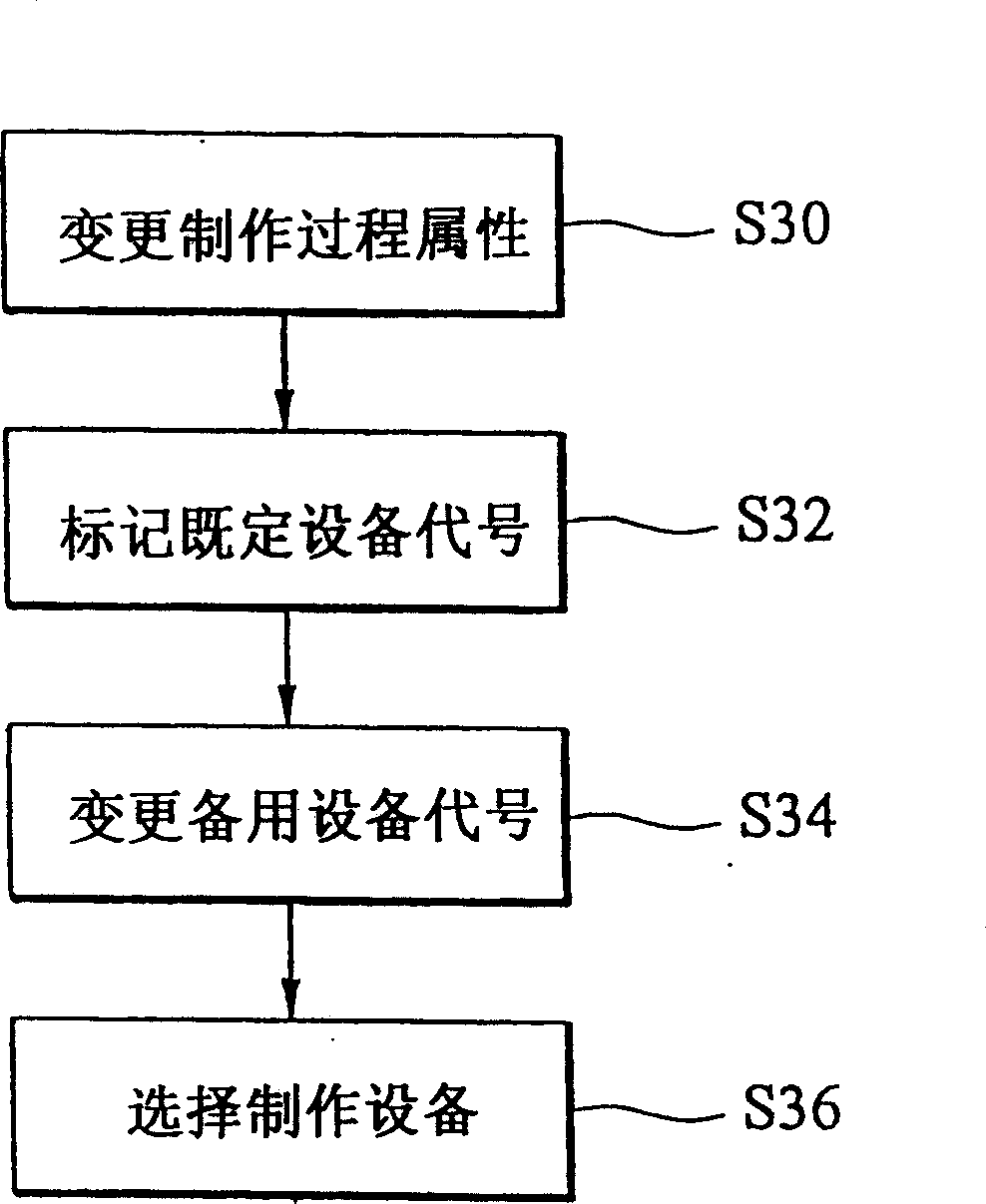

[0017] The following fit Figure 1 to Figure 3 The semiconductor manufacturing process control system and the method for handling the change of the manufacturing process attribute of the semiconductor equipment according to the embodiment of the present invention are described.

[0018] figure 1 It is a schematic diagram of a semiconductor manufacturing process control system according to an embodiment of the present invention. The system is used to process the change of manufacturing process attributes of multiple semiconductor devices, and at least includes an equipment data module 10 , a manufacturing process data module 20 and an operation interface 30 . The device data module 10 is used to store a plurality of device codes 10a (for example, E 1 ,E 2 ,E 3 ,E 4 ,E 5 ), a plurality of manufacturing process attribute data 10b (for example, A, M, B, A, B) corresponding to these equipment codes 10a, and a plurality of equipment data 10c corresponding to these equipment co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com