Process and device for immersing direct-cooling continuous production of latex matrix of emulsion explosive

A technology of latex matrix and emulsified explosives, which is applied to explosives processing equipment, explosives, offensive equipment, etc., and can solve problems such as long cooling time, high energy consumption, and poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

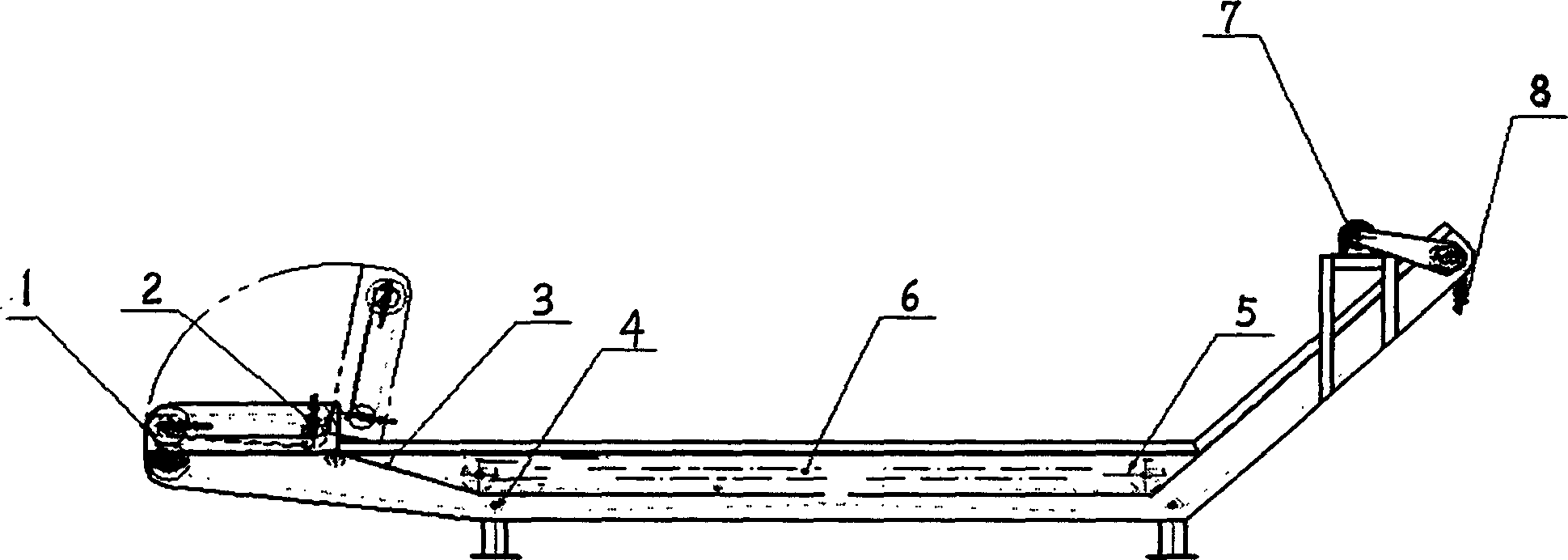

[0013] Referring to the accompanying drawings: The belt-type colloid water cooler in this embodiment is composed of a colloid distributor 1, a pressure roller 2, a conveyor belt 3, an idler roller 4, a pressure roller 5, a cooling water tank 6, a transmission mechanism 7, and a discharge mechanism 8; the colloid The distributor 1 is located above the beginning of the conveyor belt 3 and is used to distribute the colloid into a thin layer; the pressure roller 2 that can be adjusted up and down is located above the conveyor belt 3 behind the colloid distributor 1; the conveyor belt 3 is supported by the idler 4 and runs horizontally After the distance, tilt down to enter the cooling water tank 6 (the length of the cooling water tank 6 is 4 meters); the pressure roller 5 is located at the corner of the conveyor belt 3, and is used to fix the conveyor belt 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com