Powered steering system

A technology of power steering and steering valve, applied in power steering mechanism, automatic steering control components, steering mechanism, etc., can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

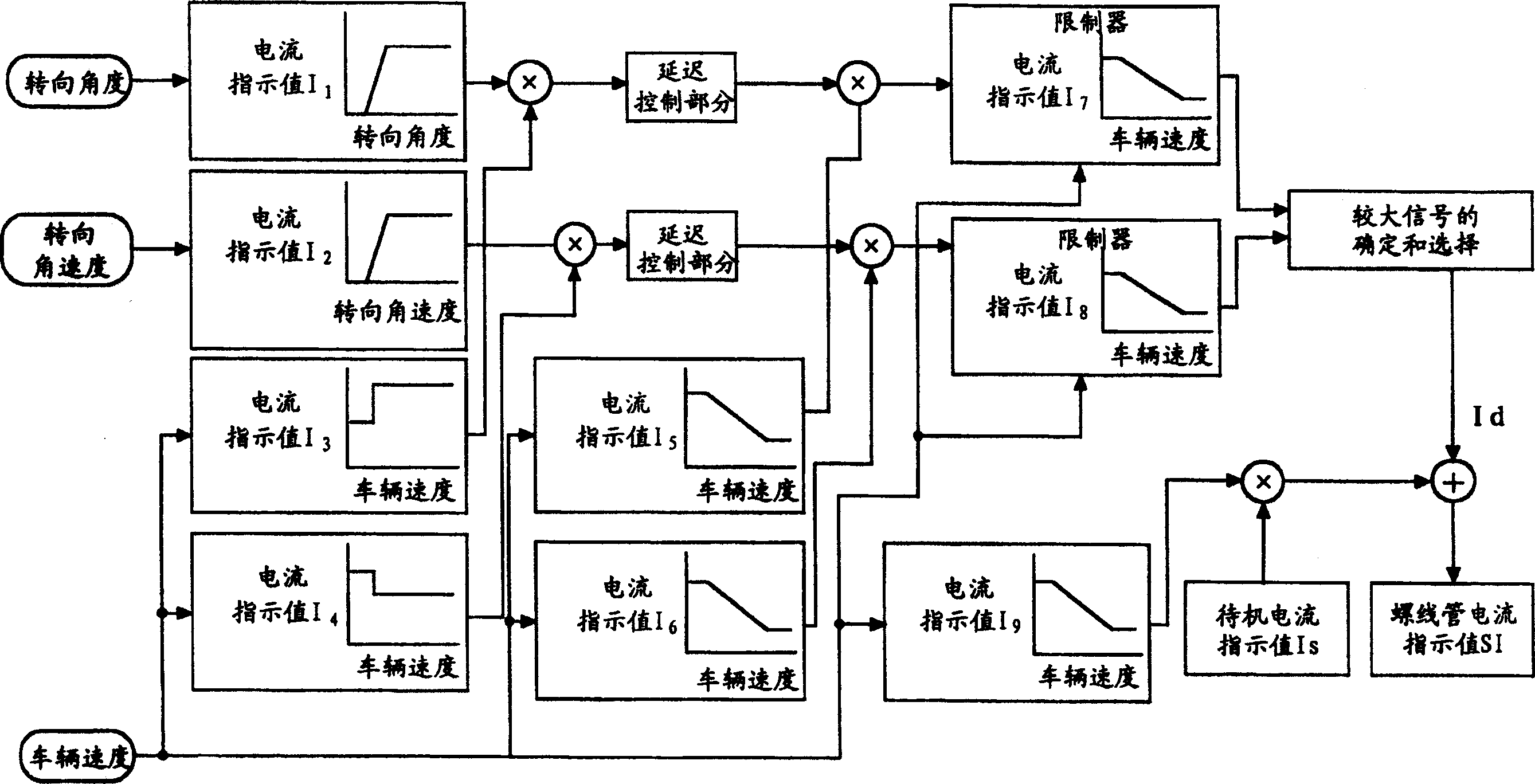

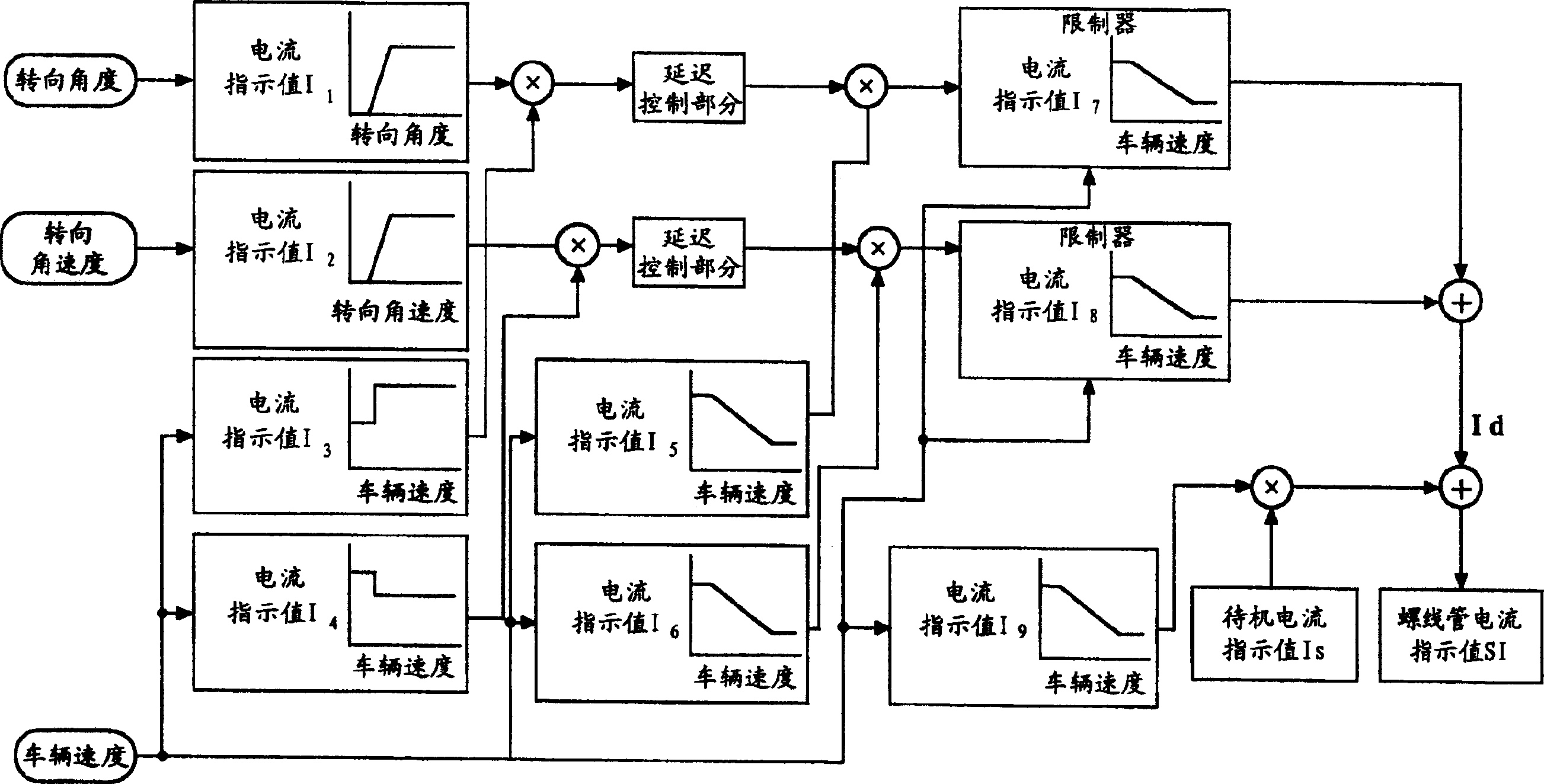

[0055] figure 1 The control system of the controller C of the first embodiment is illustrated. In the case of the first embodiment, except for the controller C, the power steering system has the same configuration as the prior art example, including Figure 7 The flow control valve V, the power cylinder 8, the steering valve 9, etc. illustrated in , and the description of the control system of the controller C will be given below.

[0056] Such as figure 1 As illustrated in , the controller C determines a current indication value I1 based on the steering angle detected by the steering angle sensor 14 and a current indication value I2 based on the steering angular velocity calculated by differentiating the steering angle. Note that a steering angular velocity sensor may be additionally provided to determine the current indication value I2 based on the steering angular velocity detected by this steering angular velocity sensor.

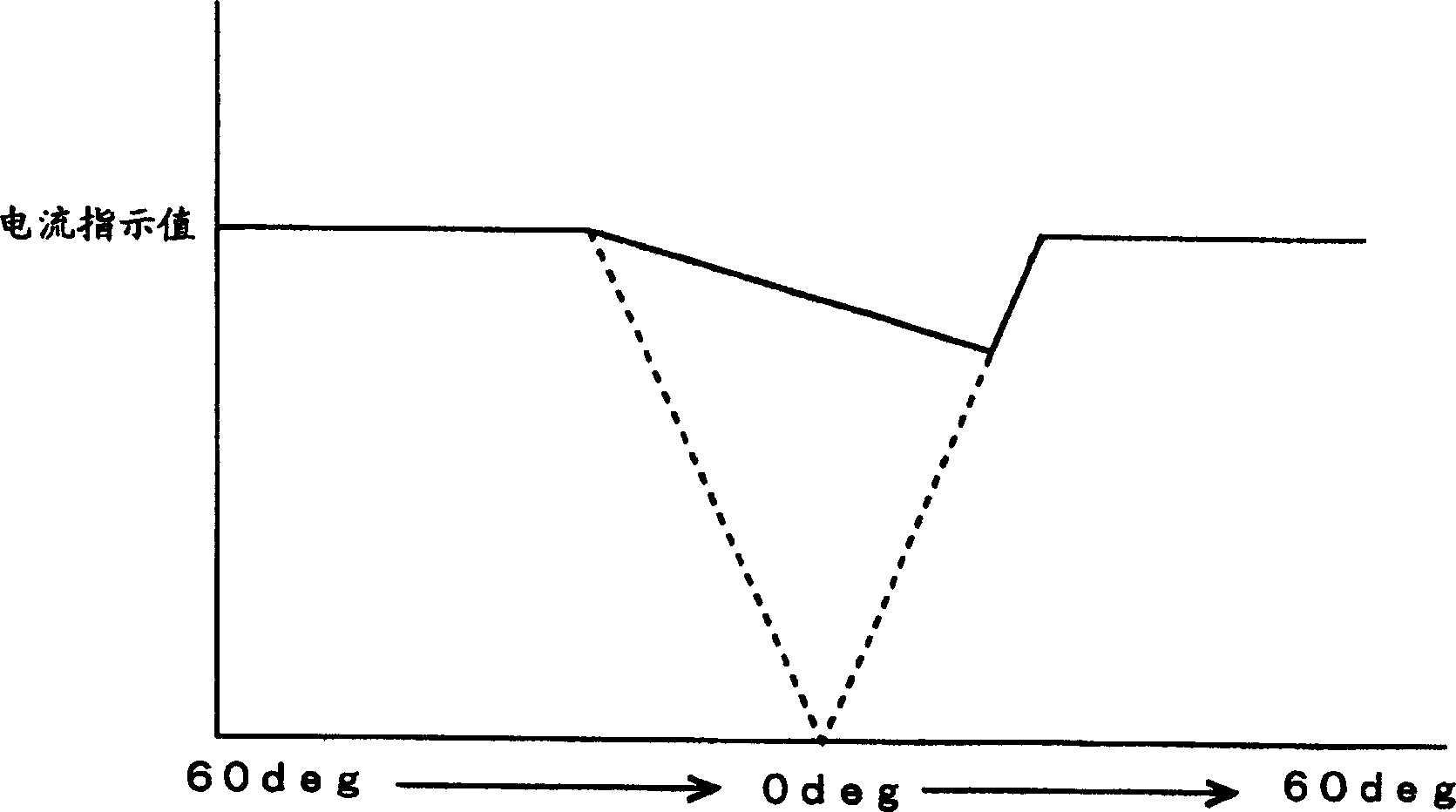

[0057] The relationship between the steering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com