Drying device

A technology of drying device and air supply device, which is applied in the direction of drying gas arrangement, drying solid material, progressive dryer, etc., and can solve the problems of large operating costs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] In order to actually verify the effect of the present invention, the present inventor actually manufactured a drying device constituted by the present invention.

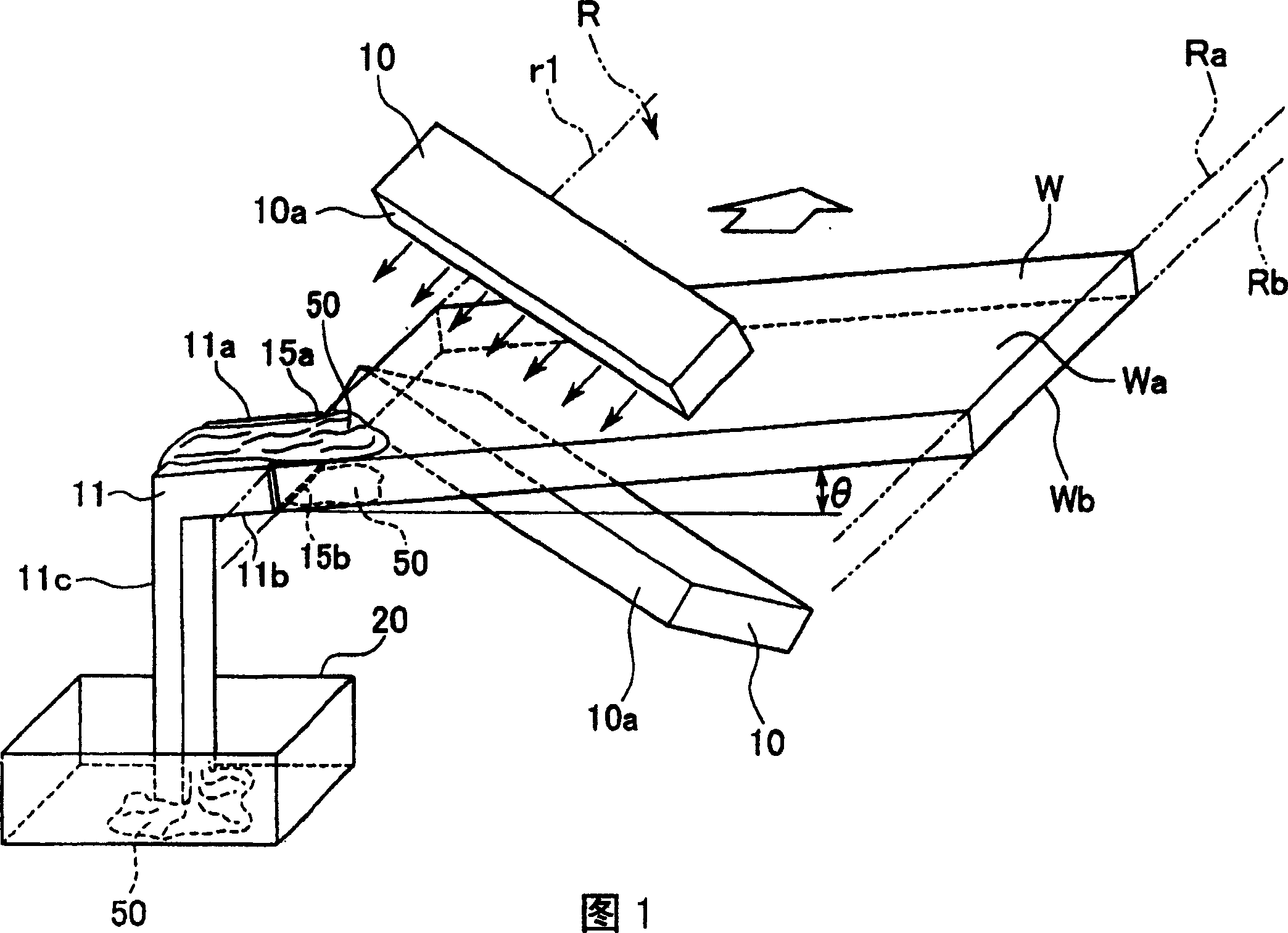

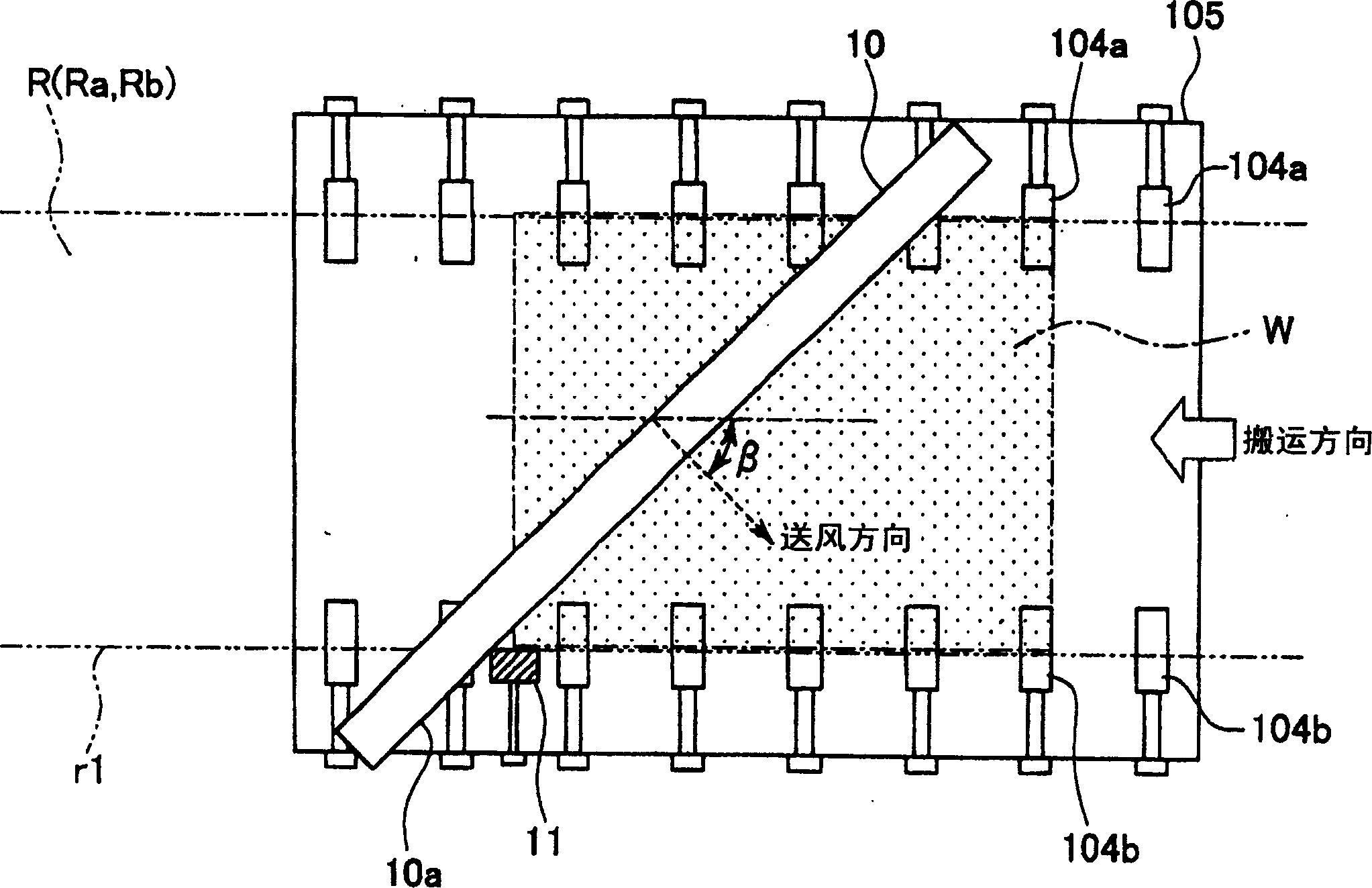

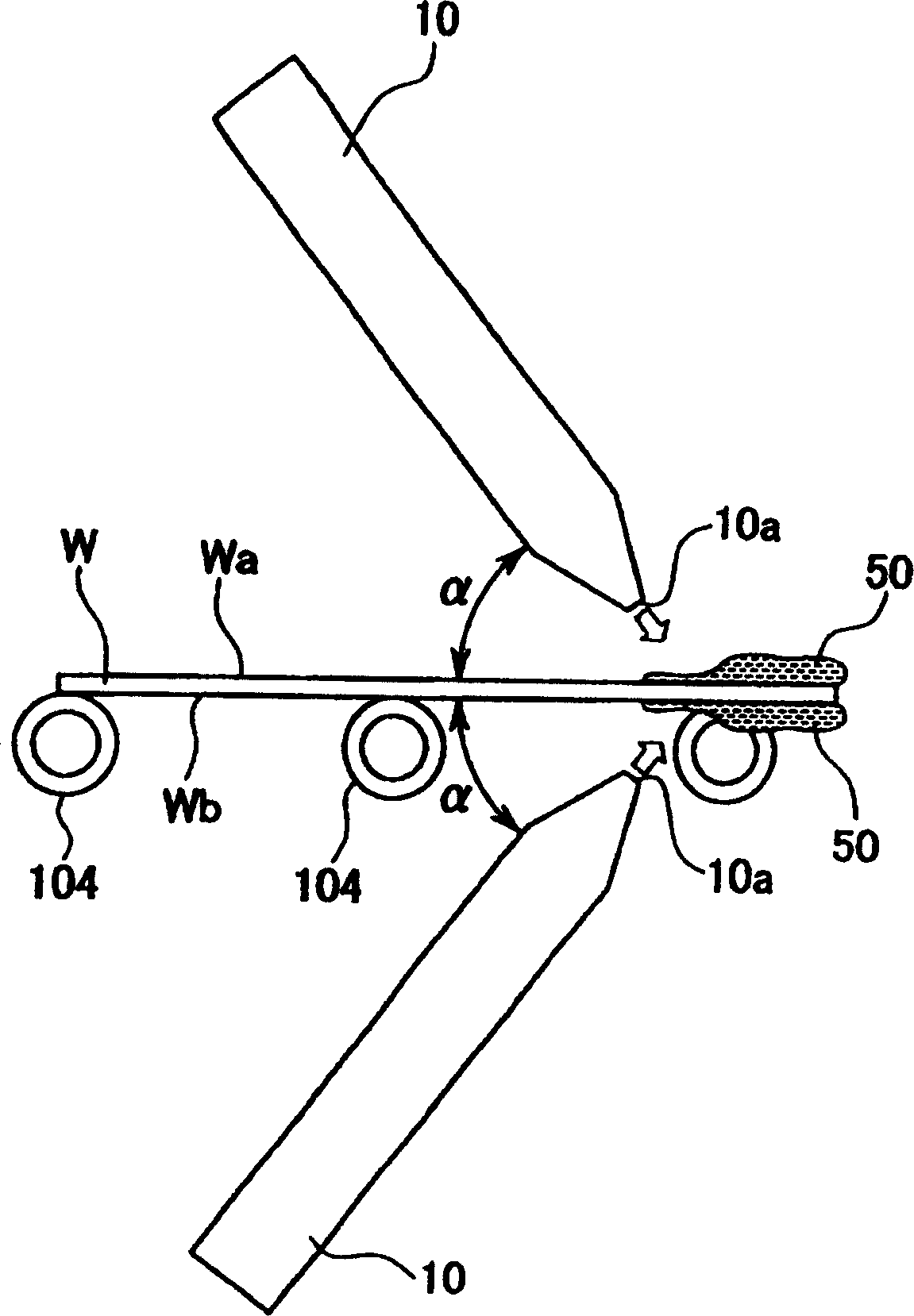

[0094] The drying apparatus of this embodiment is based on the above-mentioned embodiment 1, and the inclination angle of the substrate during transportation (that is, the inclination angle of the transportation path) is 2°, and the drying process is performed. cm) In comparison, only about 1 / 10 of the air blowing force can make the processing liquid flow from the substrate to the plate member side.

[0095] According to the present invention described in detail above, since the treatment liquid is recovered in the form of a liquid without being scattered into the air, the blowing force of the blowing device can be reduced, and the running cost for blowing can be reduced. Furthermore, since the processing liquid is recovered in a liquid state, it is not necessary to provide an additional exhaust device to rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com