Automatic screening printing method for fitting location and jetting formation in IMR process

A technology of injection molding and screen printing, applied in printing, printing devices, etc., can solve problems such as high and low loss, poor color performance, and slow printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

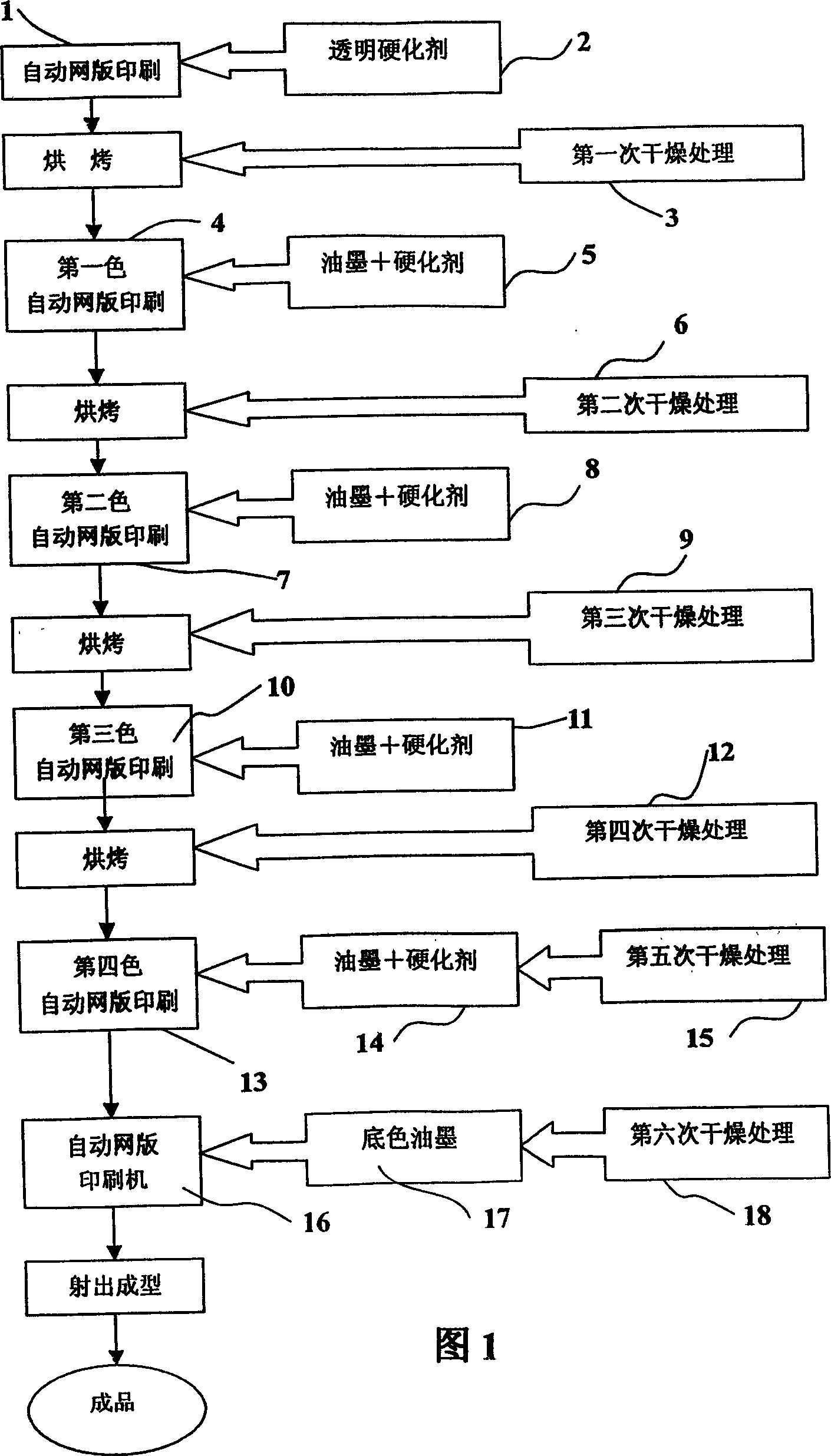

[0010] Relevant detailed description and technical content of the present invention, cooperate accompanying drawing to illustrate as follows now:

[0011] As shown in Figure 1, this figure is a schematic flow chart of the automatic screen printing method for positioning and injection molding in the IMR process of the present invention. The automatic screen printing method for positioning and injection molding in the IMR process of the present invention mainly has low loss, not only fast printing speed, excellent color expression, and can be used in conjunction with positioning and injection molding machines, and provides various The printing method of the color variation.

[0012] In order to complete the above method, the steps of the present invention include: the first screen printing, baking, the second color printing and baking according to the pattern requirements, the last color printing, baking and injection molding steps;

[0013] At first, the first step is to use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com