Wall board of support

A wall panel and wall surface technology, applied to the parts of the instrument, rack/frame structure, instrument, etc., can solve the problems of waste and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

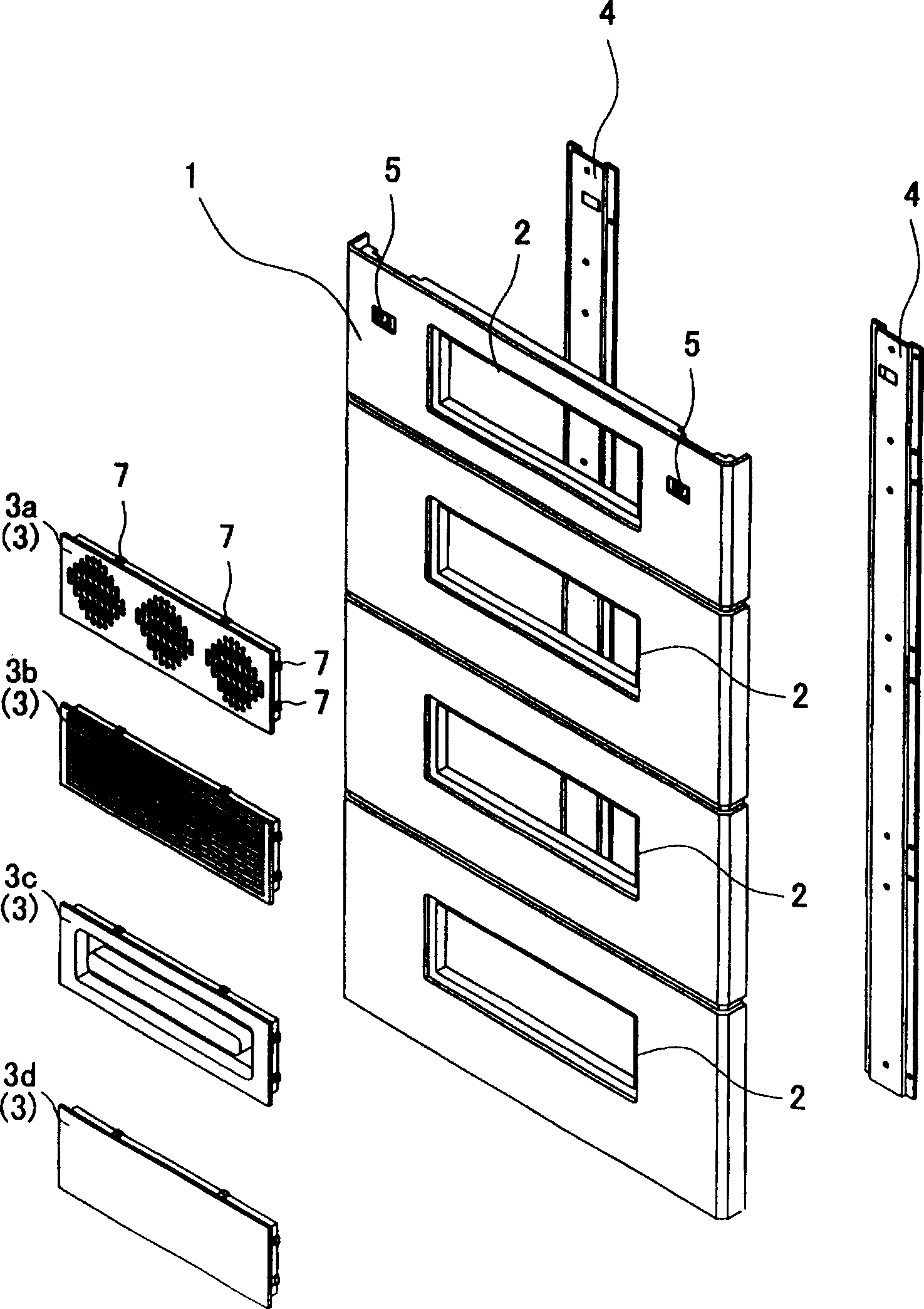

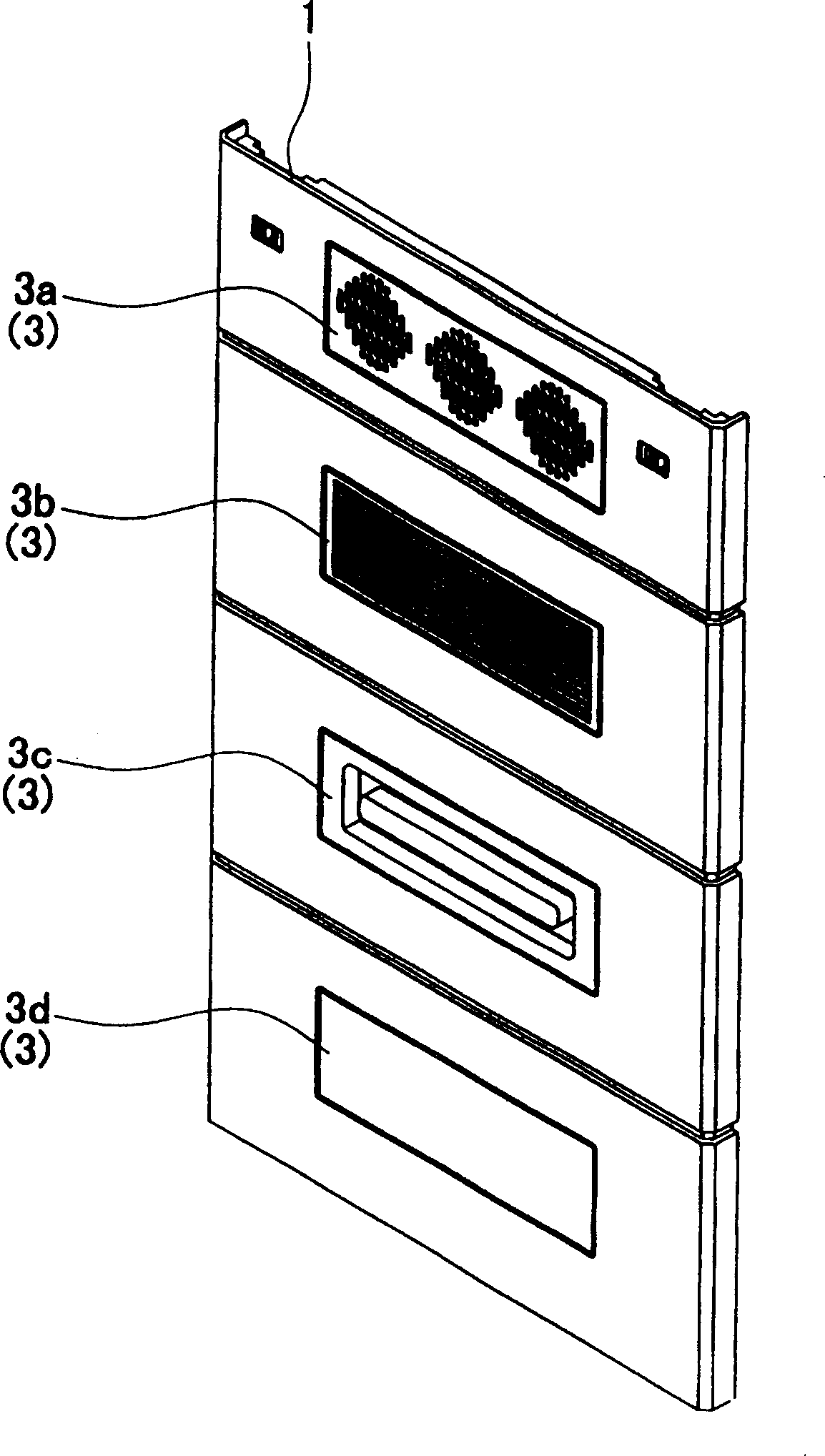

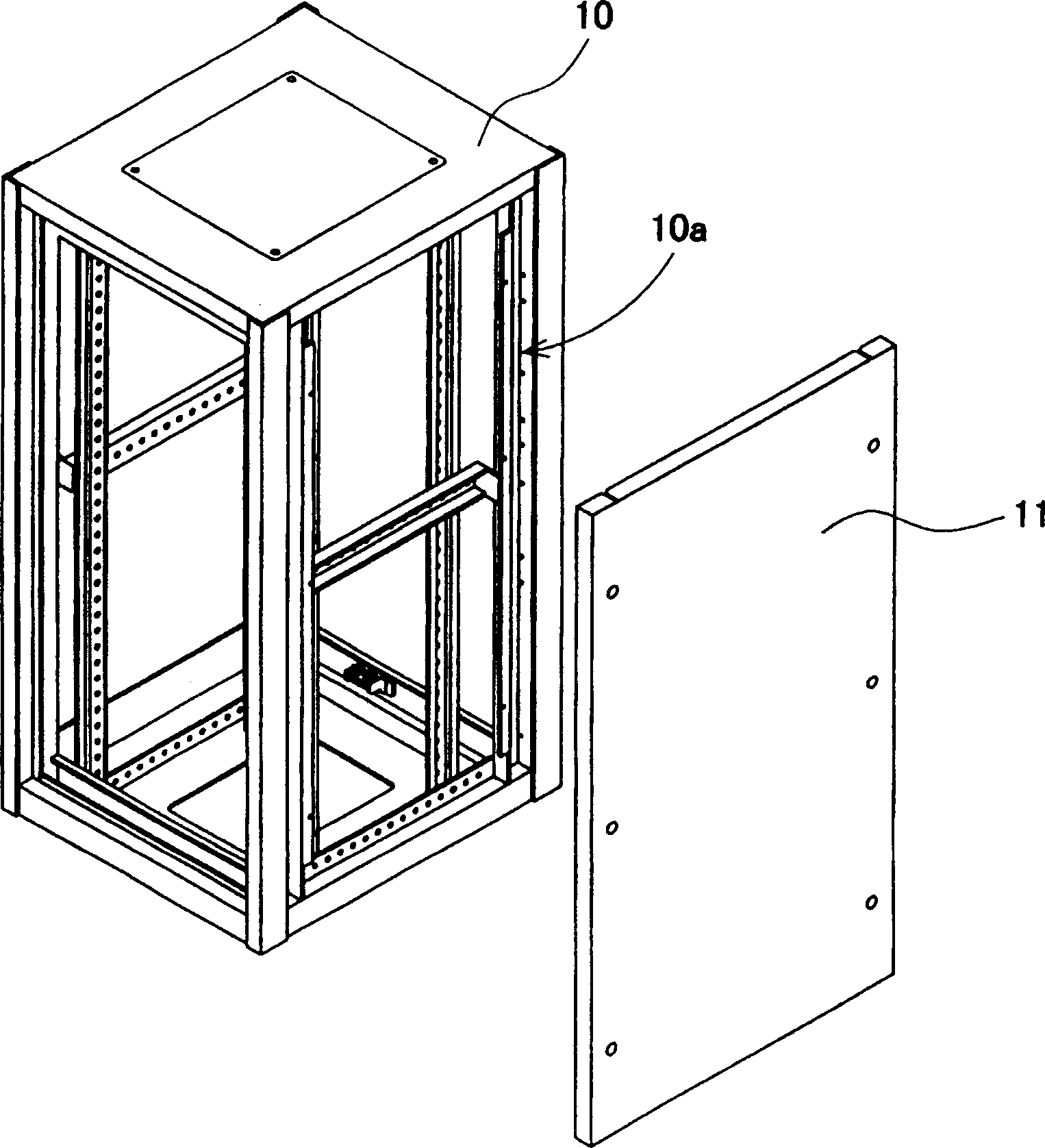

[0012] specific implementation

[0013] Embodiments embodying the present invention will be described in detail below with reference to the accompanying drawings. figure 1 It is an exploded oblique view of the wall panel of the bracket related to the present invention, figure 2 Indicates its assembled state. In the figure, 1 is a wall panel body having four openings 2, 3 (3a...3d) is a functional panel attached to the opening 2 of the wall panel body 1 according to the specifications, and 4 is a wall panel arranged on the wall panel The support rods on the left and right sides of the main body 1.

[0014] The wall panel main body 1 has a shape to cover wall surfaces (not shown) such as the side surface and the back surface of the bracket to be attached, and is formed by resin molding. The opening part 2 is formed in four steps up and down, and any one of them is a horizontally wide rectangle and is formed in the same size. Furthermore, well-known attachment levers 5 are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap