Electric connector for electric tool

A technology of electric tools and electrical connectors, applied in the direction of multi-purpose hand tools, connections, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

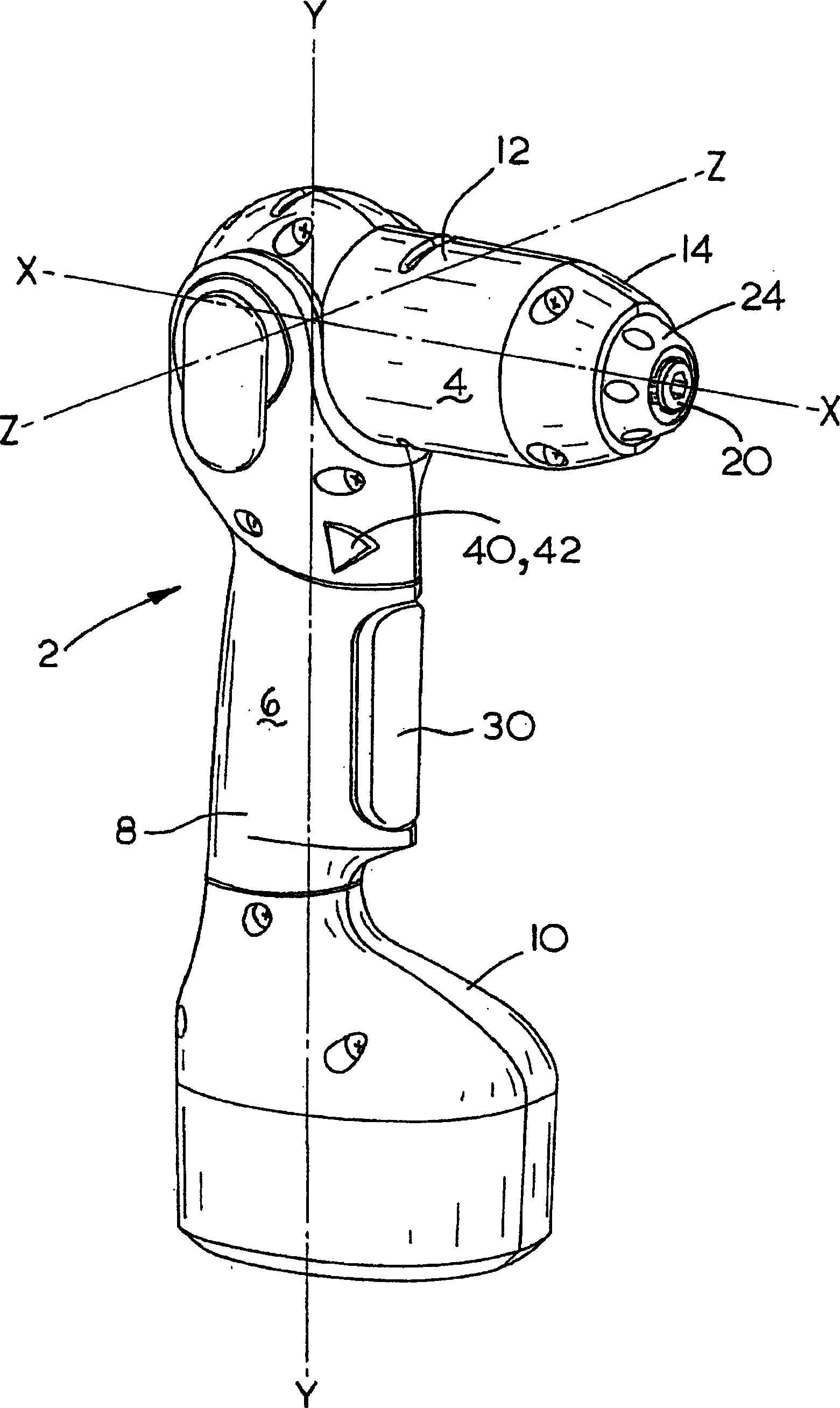

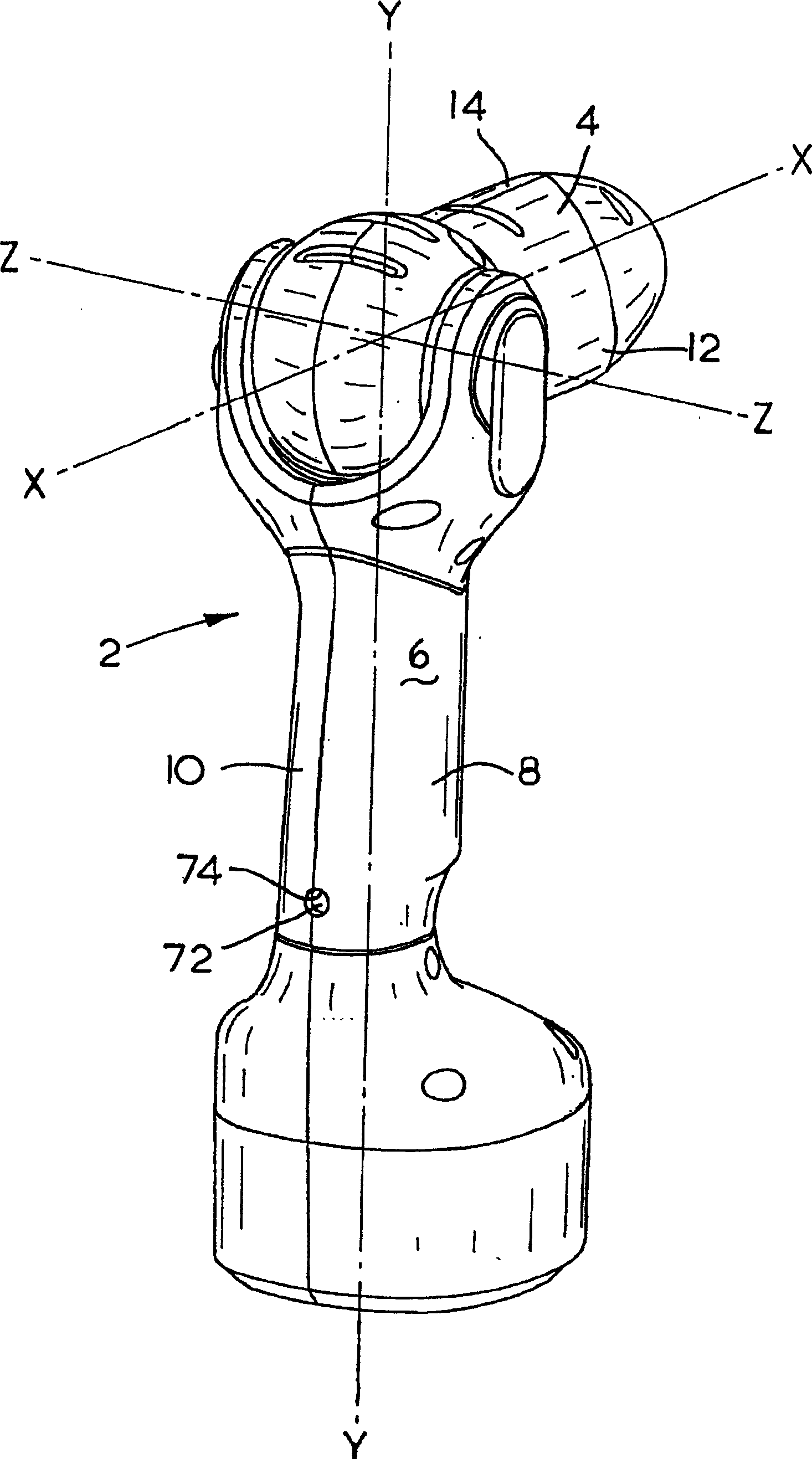

[0041] see figure 2 and 3 , an electric tool, generally indicated by reference numeral 2, which is an electric drill consisting of a cylindrical drill bit 4 and an elongated handle 6, said drill bit having a longitudinal axis X, said handle disposed about a longitudinal axis Y . The drill bit 4 is pivotally mounted on the handle 6 and pivots around an axis Z relative to the handle 6 . The handle 6 is formed by a first housing 8 and a second housing 10, which are connected by a number of screws (not shown). The drill bit 4 is formed by a third housing 12 and a fourth housing 14, which are connected by a plurality of screws (not shown).

[0042] Referring to FIGS. 4 and 5 , the drill bit 4 is composed of a motor 16 and a transmission gearbox (not shown) with an output shaft 20 . The motor 16 and gearbox are housed in the drill head 4 . The front end of the drill bit 4 is provided with a cylindrical gearbox housing 22, which surrounds the gearbox and the output shaft 20. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap