Actuator arrangements

An actuator device and actuator technology are applied in transportation and packaging, hydraulic equipment for manipulating turnouts or line breakers, electrical equipment for manipulating turnouts or line breakers, etc., which can solve the problem of interrupting railway traffic , Dangerous signals and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

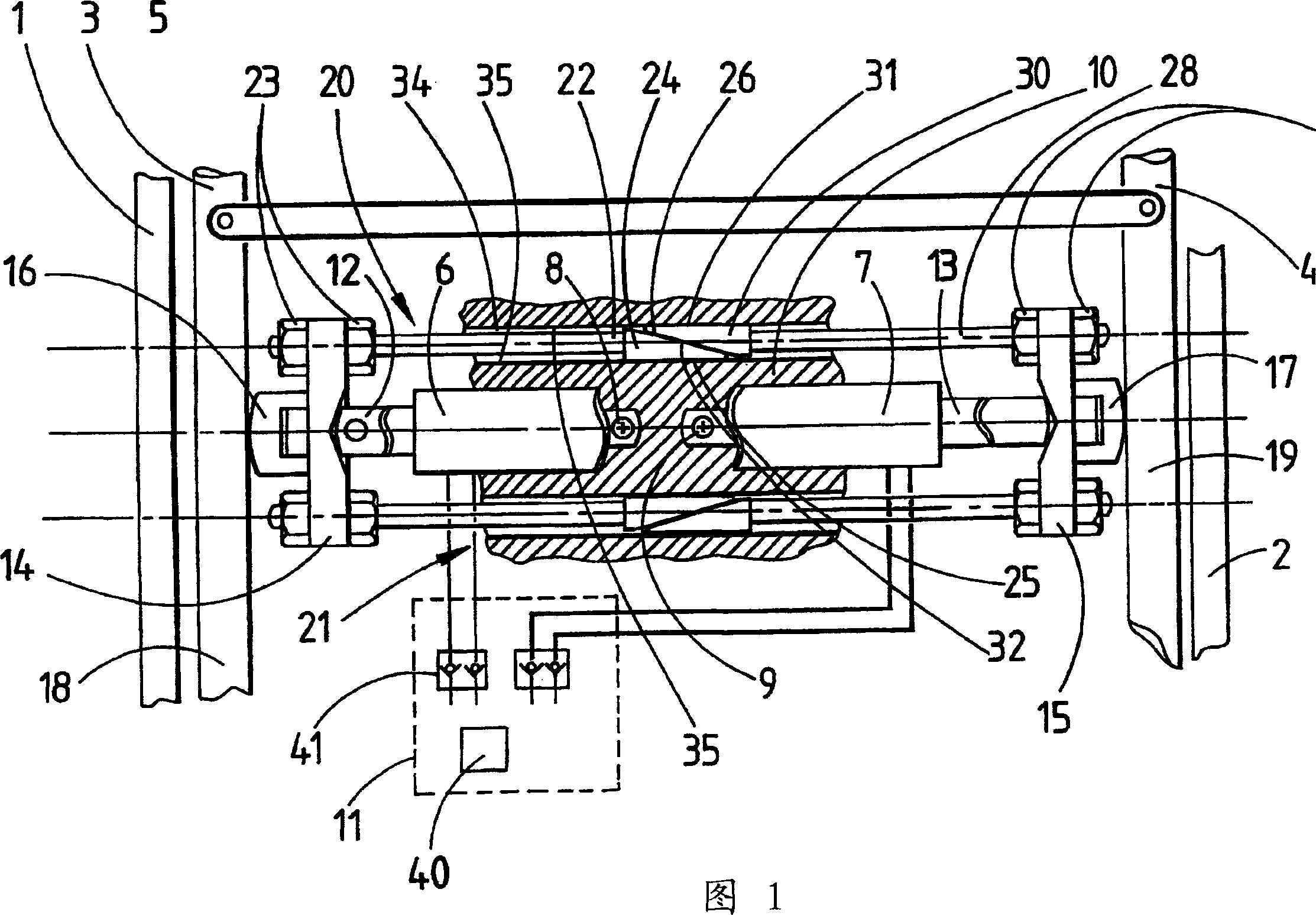

[0010] Referring to Figures 1 and 2, the actuator arrangement is located between a pair of fixed main rails 1 and 2 and a pair of movable members extending between said main rails in the form of a pair of Switch rails 3 and 4. A connecting bar or gauge bar 5 extending transversely between the two switch rails connects the two switch rails together.

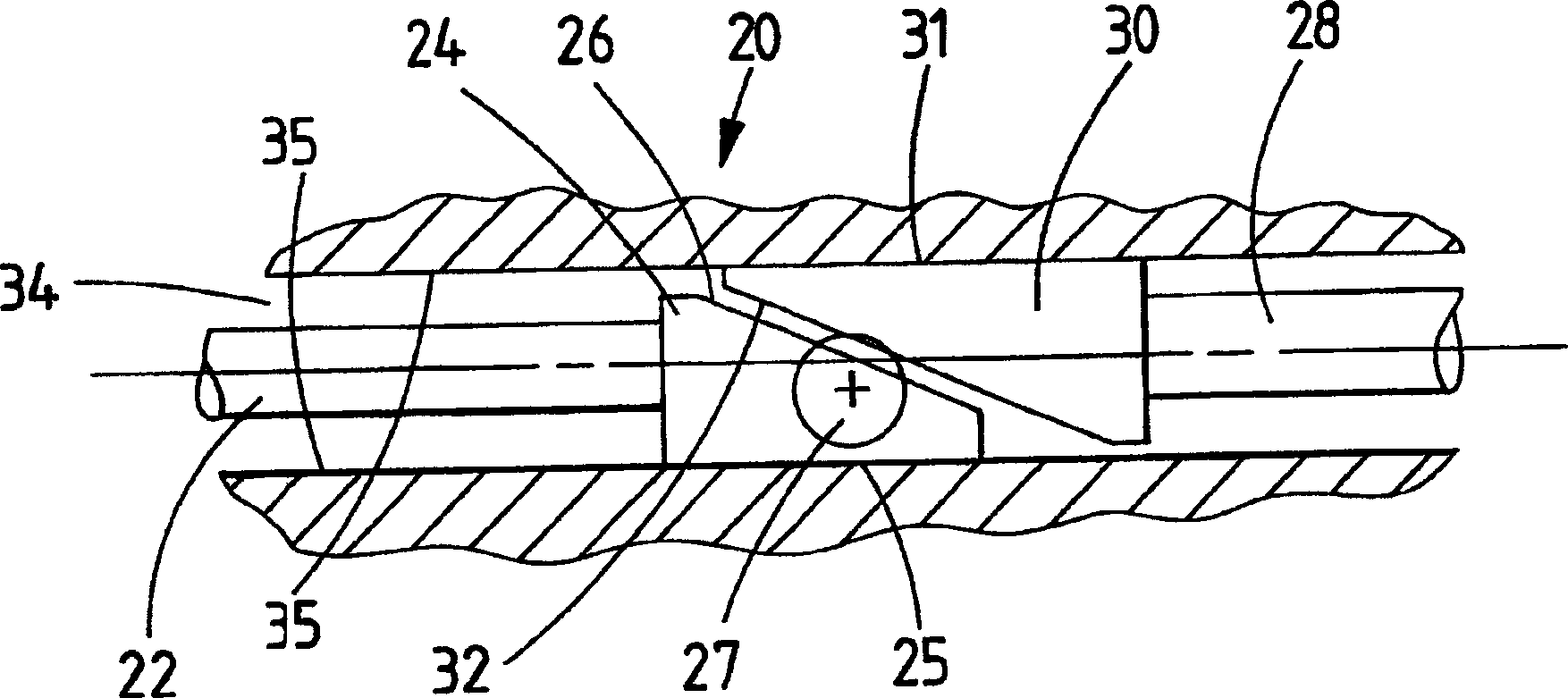

[0011] This actuator arrangement consists of two conventional hydraulic actuating cylinders 6 and 7 fixed at their bases 8 and 9 to a sleeper 10 or other fixed structure, the two hydraulic actuating cylinders 6 and 7 being aligned with each other , extending laterally outward. Cylinders 6 and 7 are driven by fluid from a conventional hydraulic source, indicated generally at 11 . Pistons 12 and 13 of cylinders 6 and 7 support brackets 14 and 15 respectively, and insulating nylon brushes 16 and 17 are respectively provided on the outside of the brackets. The brushes 16 and 17 bear against the inner surfaces 18 and 19 of the switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com