Method and apparatus for picking blank stack

A technology of stockpiles and blanks, applied in the field of cigarette packing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

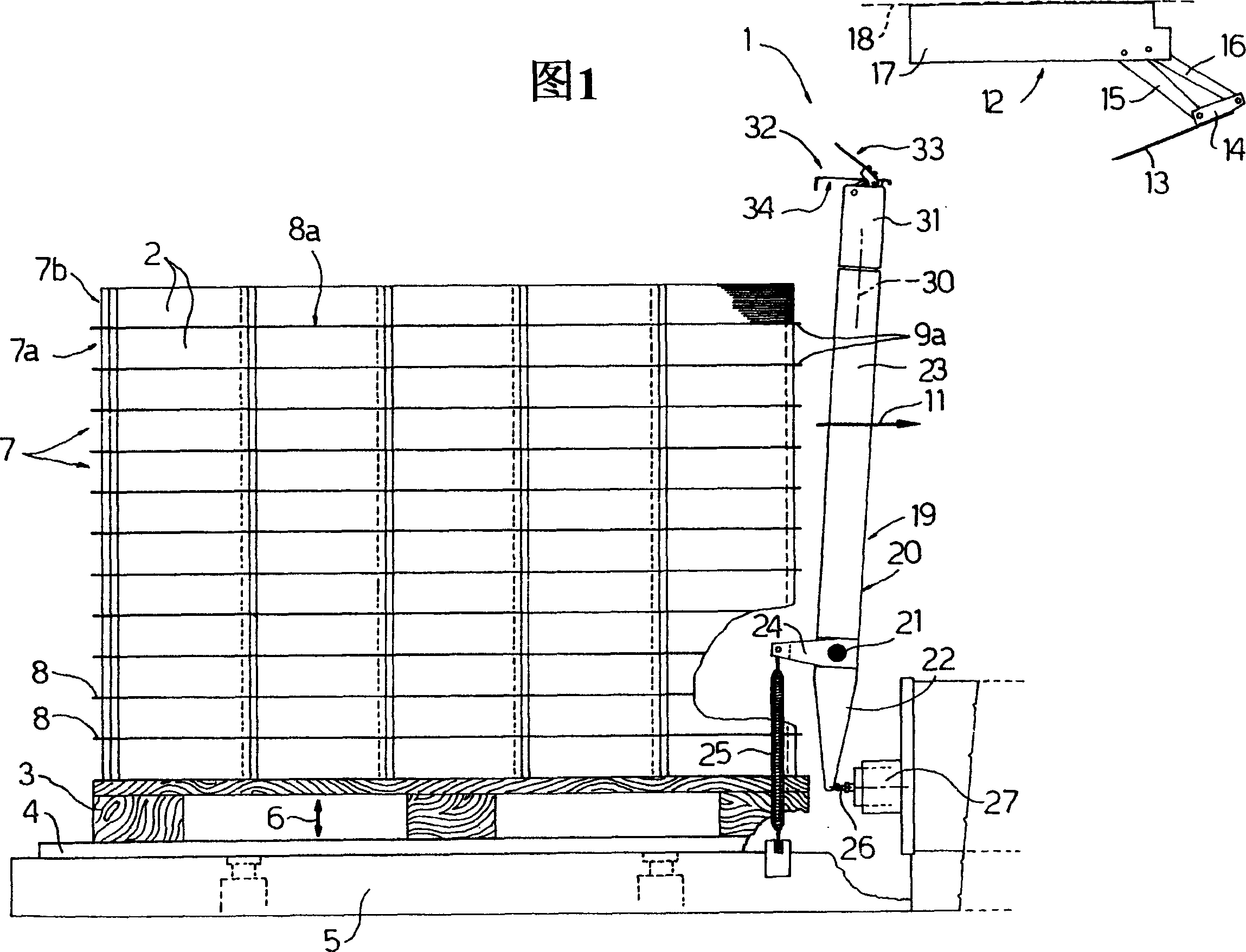

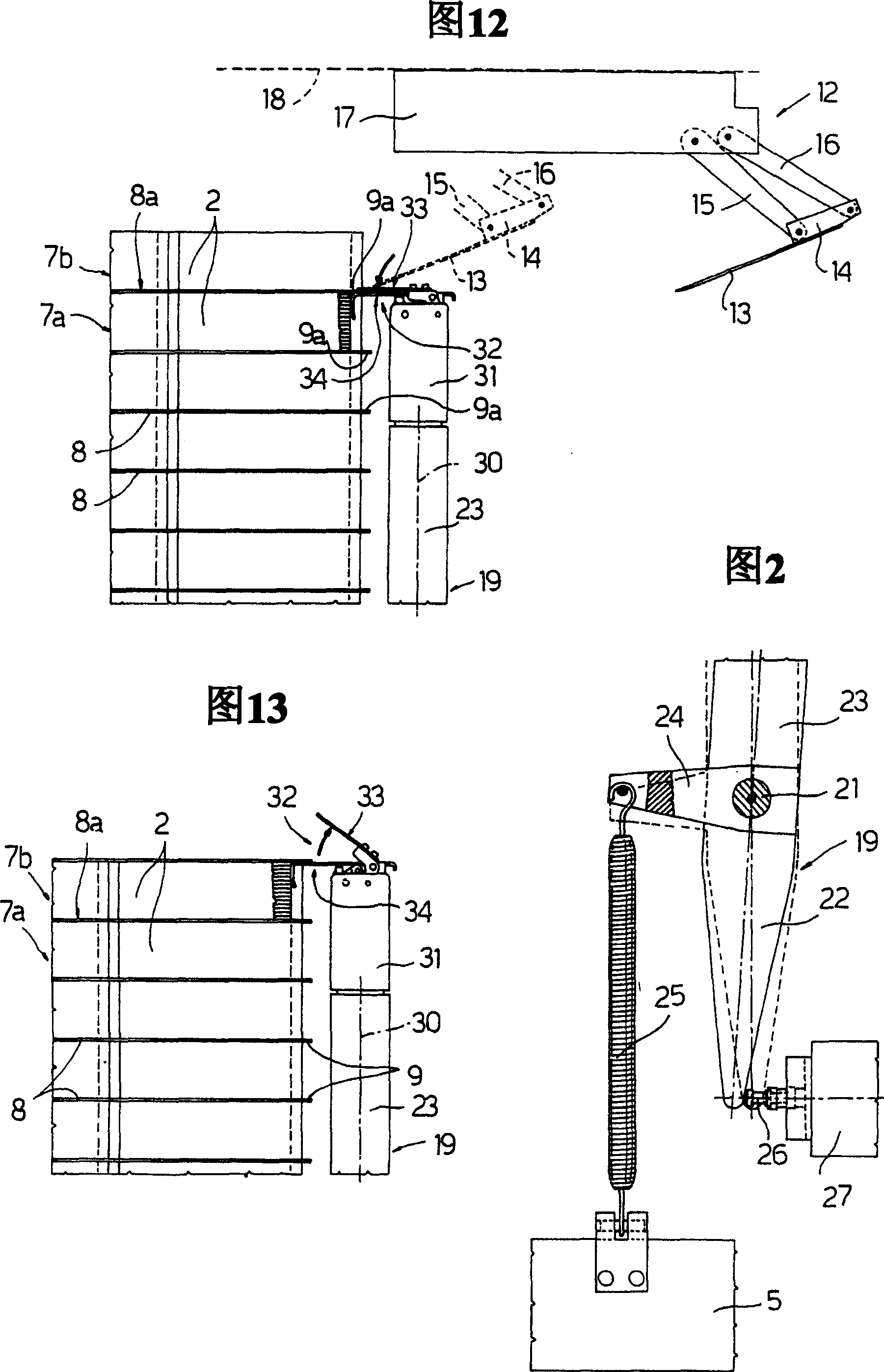

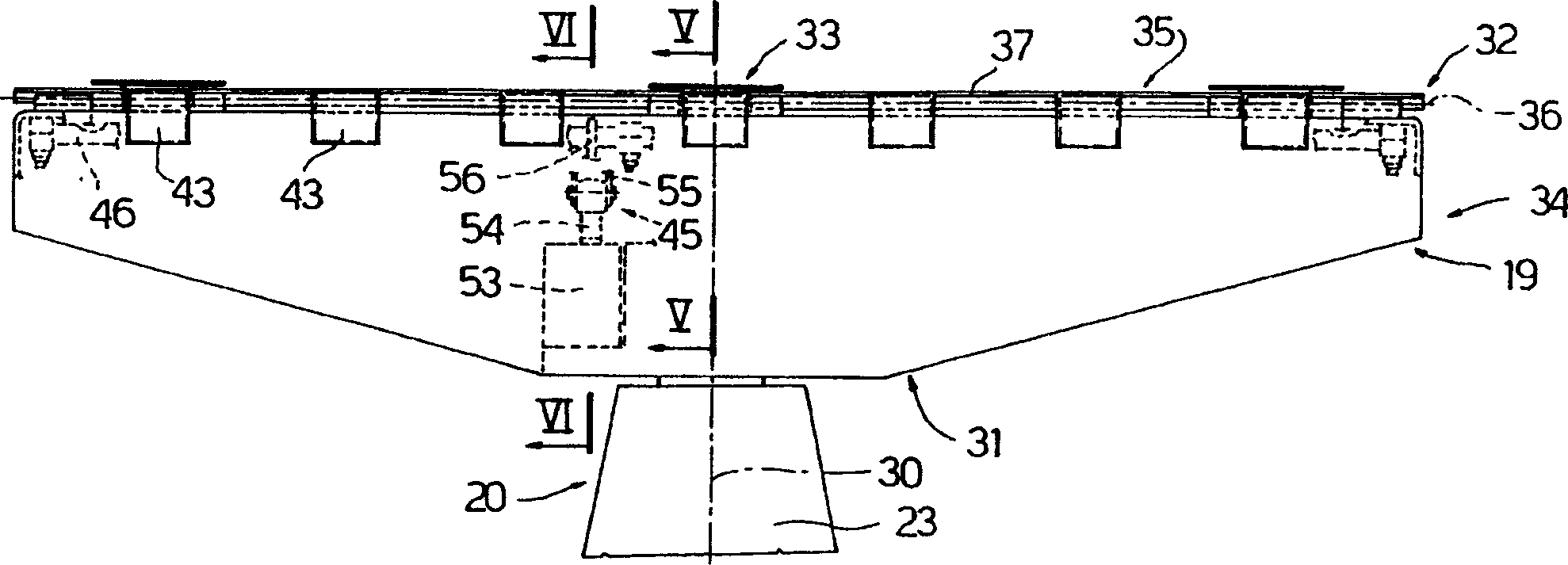

[0018] Reference numeral 1 in FIG. 1 designates the entirety of a pick-up device for continuously picking up blank stockpiles 2 from a pallet 3 lying on a substantially horizontal plane 4 . The plane is supported by a base frame 5 and is movable relative to the frame 5 in a substantially vertical direction 6 . The stockpile 2 is stacked on a pallet 3 and consists of several superimposed layers 7, each layer being separated from the layer 7 below by a partition 8, usually made of cardboard or the like. The edge portion 9 ( Figure 4 ) protruding from the periphery of layer 7. Figure 1 and Figure 4 As shown more clearly in , in each layer 7 the piles 2 are arranged in parallel rows 10 along direction 11 .

[0019] Referring to FIG. 1 , the pick-up device 1 comprises a pick-up assembly 12 which crosses the direction 11 and faces a portion 9 a of the edge portion 9 of each partition plate 8 . The pick-up assembly 12 comprises a hinged fork 13 protruding in direction 11 from o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com