Spray head installing method of ink-jet printing machine

A technology of inkjet printer and installation method, which is applied in printing and other directions, can solve problems such as volume, weight, heavy mass, and increased manufacturing cost, and achieve the effects of high physical precision, high printing efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

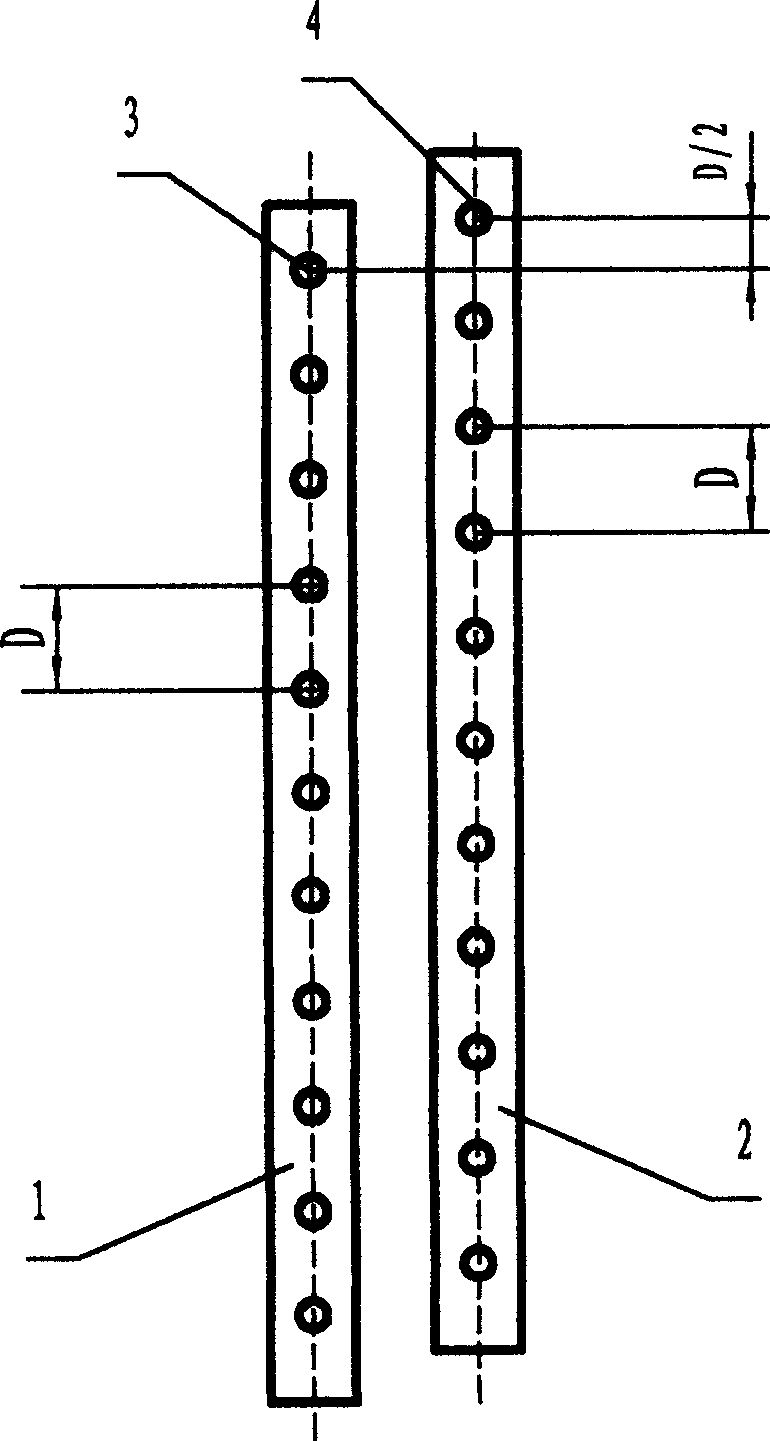

[0018] see figure 1 , In the technical scheme of the present invention, there are two nozzles 1,2 that use the same color ink, and the nozzle holes 3,4 of the two nozzles 1,2 are arranged in parallel to each other, and the nozzle hole physical spacing is D. The installation method of each nozzle is 1 / 2 of the nozzle hole spacing D between the nozzles, that is, 1 / 2 dislocation parallel connection.

Embodiment 2

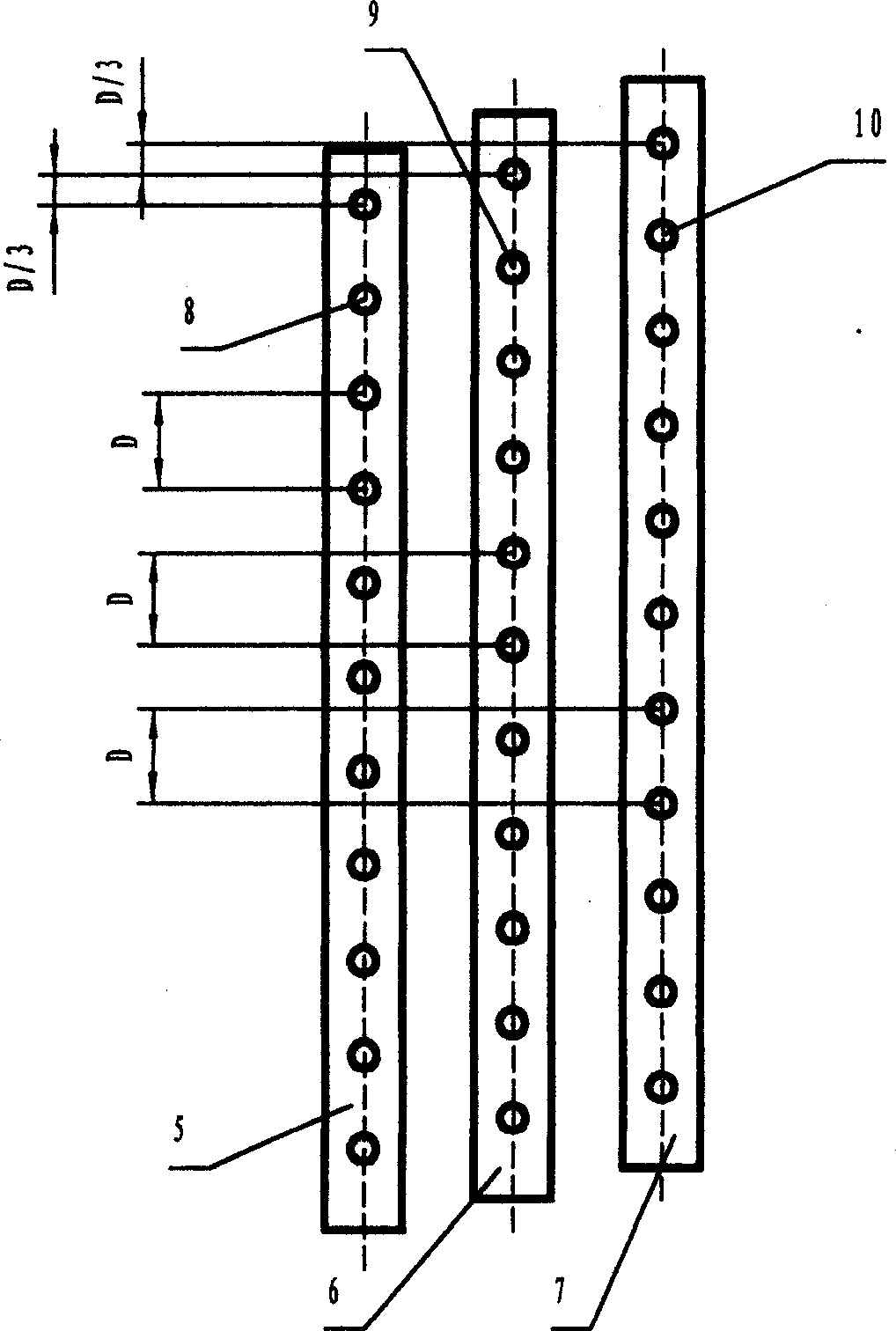

[0020] see figure 2 , there are three nozzles 5, 6, 7 using the same color ink, the arrangement lines of the nozzle holes 8, 9, 10 of the three nozzles 5, 6, 7 are all parallel to each other, and the physical distance of the nozzle holes is D. The installation method of each nozzle is 1 / 3 of the distance D between the nozzles, that is, 1 / 3 of the misalignment and parallel connection.

Embodiment 3

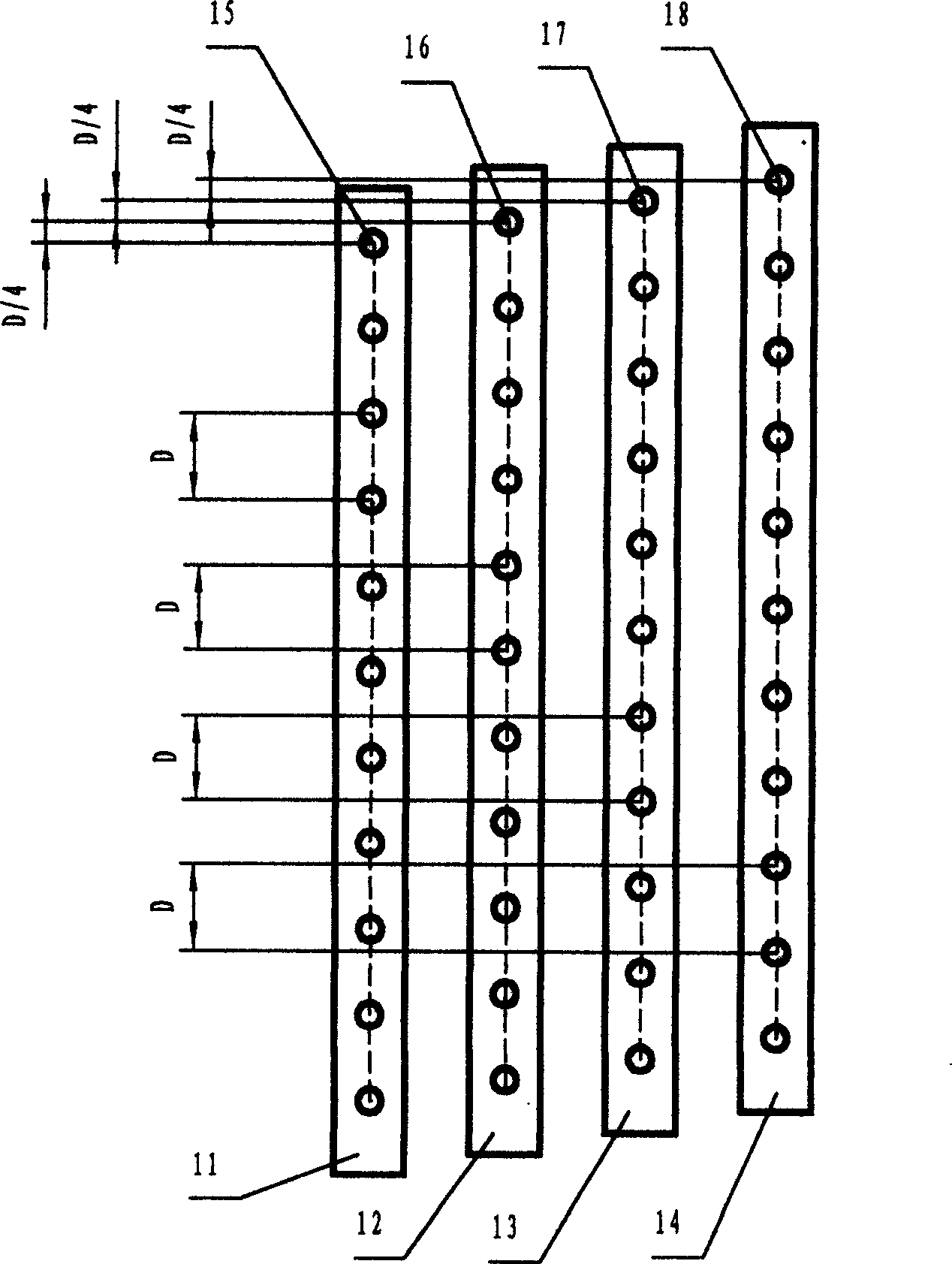

[0022] see image 3 , there are four nozzles 11, 12, 13, 14 using the same color ink, the arrangement lines of the nozzle holes 15, 16, 17, 18 of the four nozzles 11, 12, 13, 14 are all parallel to each other, and the physical spacing of the nozzle holes is D . The installation method of each nozzle is 1 / 4 of the nozzle hole spacing D between the nozzles, that is, the 1 / 4 displacement parallel type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com