Folding pressure-resistant multipass biaxial flow screw plate heat exchanger

A biaxial flow, heat exchanger technology, used in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of small processing capacity, difficult maintenance, and low operating pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

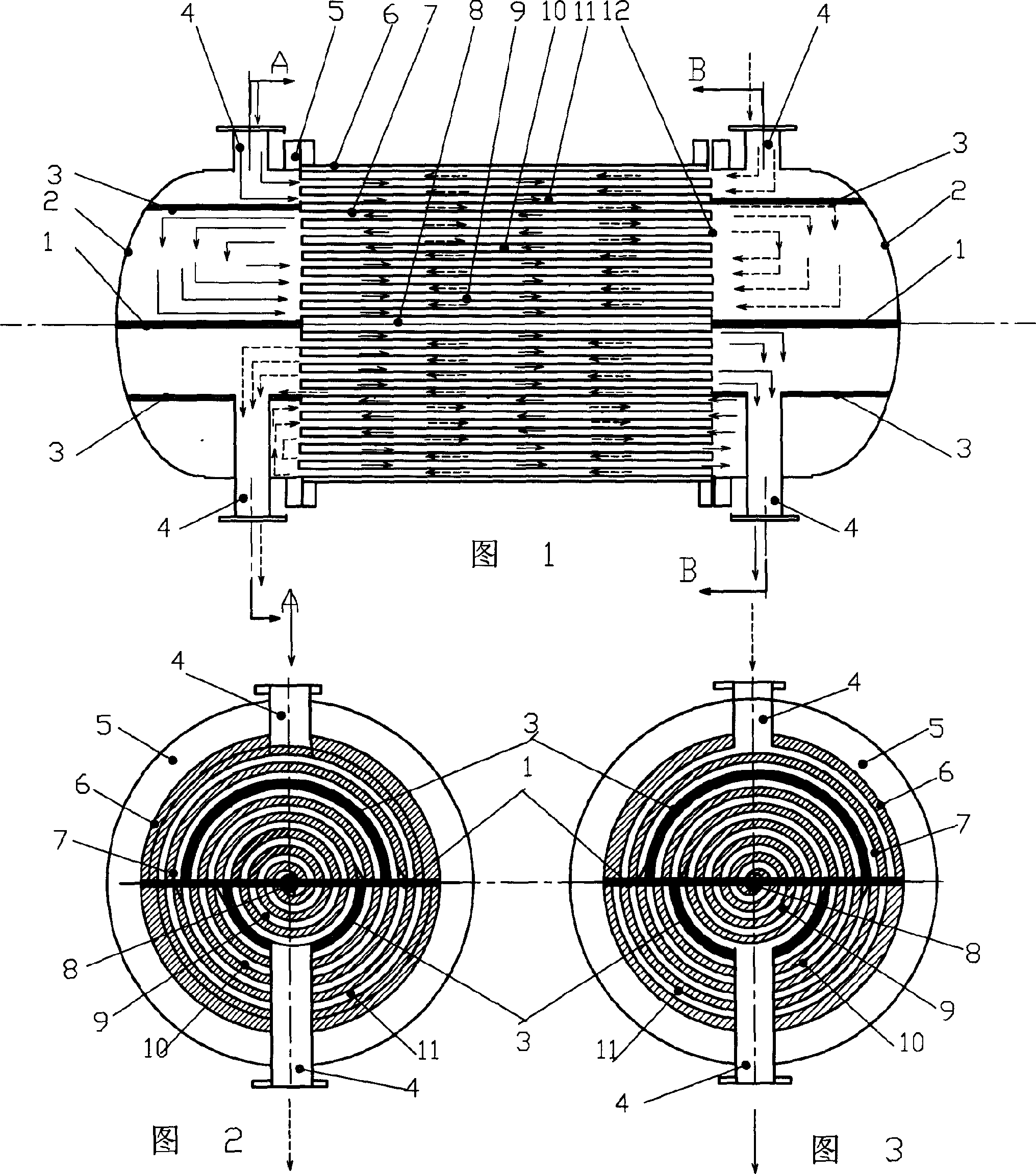

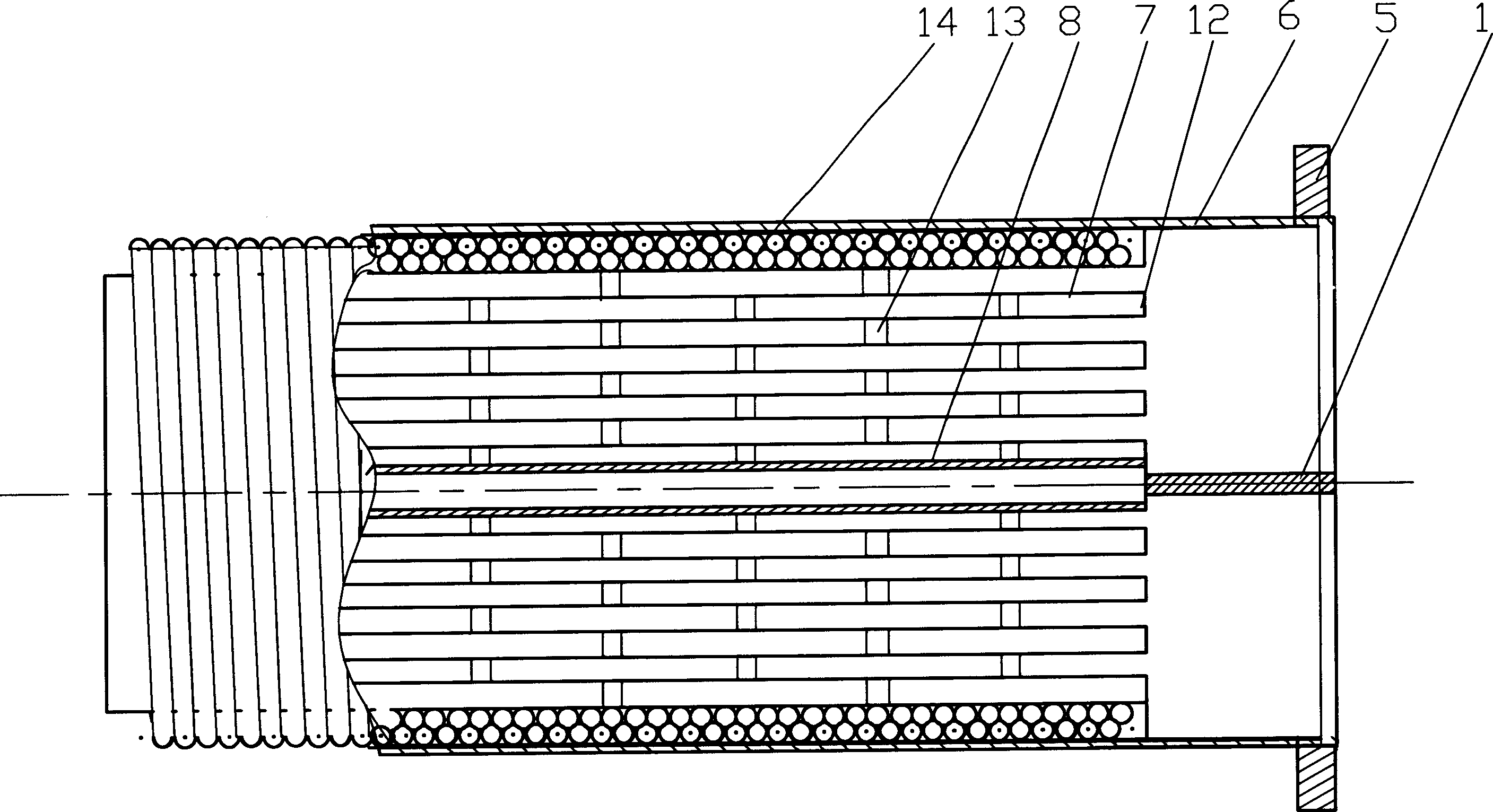

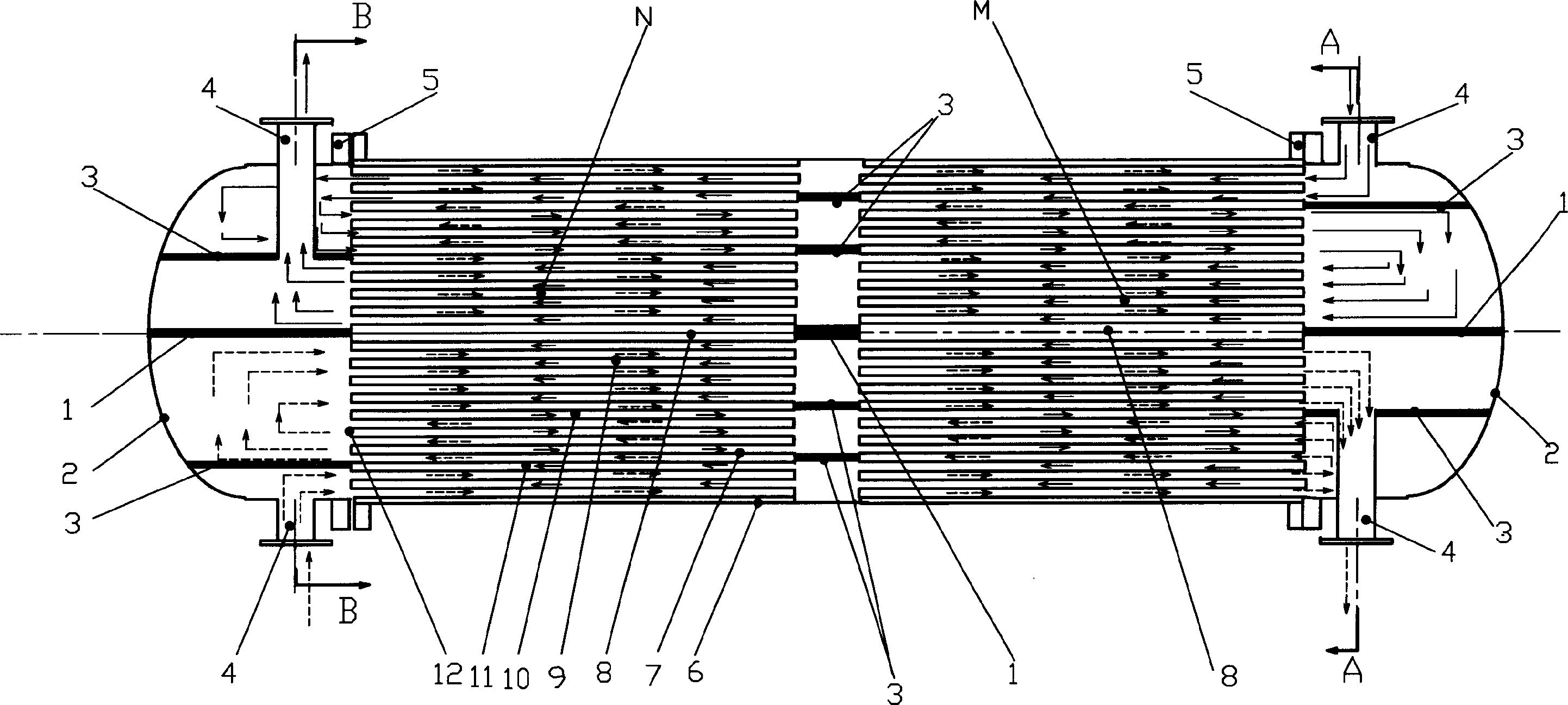

[0007] In Fig. 1, three courses are selected as a representative, (of course not limited to this). In the figure, from the center tube to the outside (taking 18 circles as an example), mark No1#∽18# circles, (numbers are not shown in the figure) the cold process fluid (indicated by a dotted lead line) takes an odd number of circles, and the hot process fluid (Represent with real lead line) take even circle, 1.3.5.7# and 2.4.6.8# are I course, 9.11.13# and 10.12.14# are II course, 15.17 and 16.18# are III course. When designing, when the heat exchange fluid has no phase change, the effective flow cross-sectional area of each process should be made equal as much as possible, and when the fluid has a phase change, the flow cross-sectional area should be selected based on the optimized fluid flow rate. The main partition 1 divides the heat exchanger into upper and lower parts. The upper odd-numbered circles at the left end of the heat exchanger (see Figure 1 and Figure 2) are cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com