Method and device for producing laminate

A manufacturing method and lamination device technology, which can be applied to lamination devices, manufacturing tools, additive manufacturing, etc., and can solve problems such as component parts falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

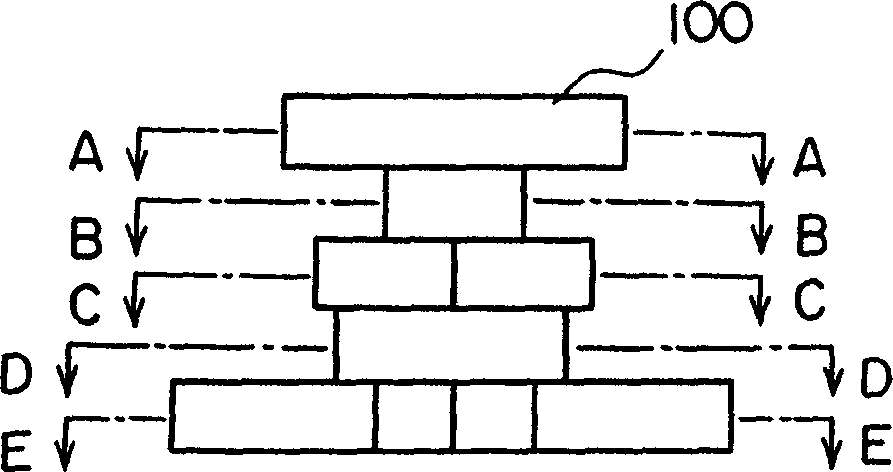

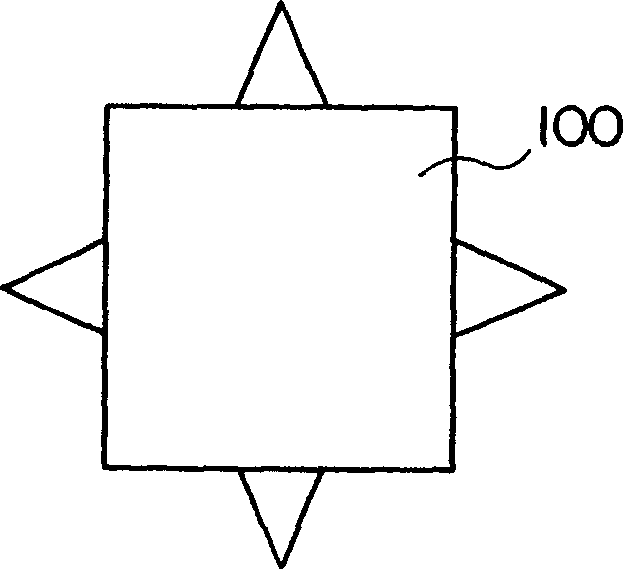

[0050] Fig. 3 is an explanatory diagram showing a laminated body and constituent members in an embodiment of the present invention, (a) and (b) are the front and plane faces of each laminated body, and (c) to (g) are diagrams of constituent members constituting each laminated body top view.

[0051] In FIG. 3, the laminated body 100 is, for example, an object having substantially the same shape as that shown in FIG. ), the component has an outline corresponding to the cross-sectional shape at each height position.

[0052] 106 is a pin hole (also called a half-piercing hole), which is formed in the same relative position and with the same shape and size in the middle part of the plane of each component 101-105 by the following method. In addition, whether each constituent member 101-105 is one or a plurality of three or more, it can be appropriately selected according to the shape and dimension of the laminated body 100 .

[0053] Figure 4 It is an enlarged longitudinal sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com