Mechanism of automatically positioning to tear and back film

An automatic positioning and film unwinding technology, which is applied in the directions of automatic packaging control, transportation and packaging, packaging/bundling items, etc., to achieve the effect of tearing film and film unwinding process and continuous and uniform pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

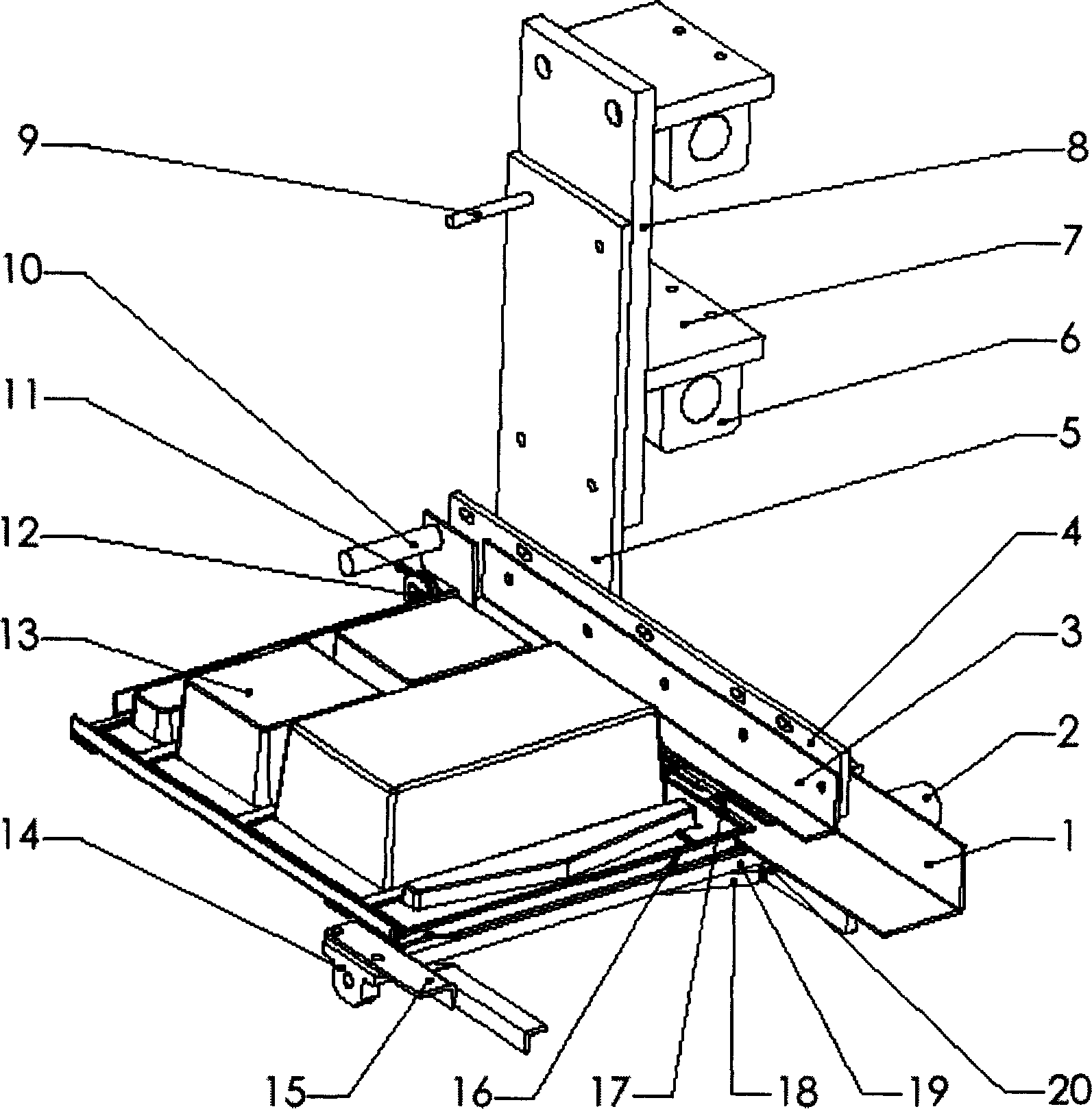

[0017] see figure 1 shown. The shaft support seat 14 is fixed on the support frame 1, supports one end of the reel 19, and the other end of the reel 19 is connected to the DC motor 2 fixed on the mounting plate 5 through a coupling 20; the box positioning frame 16, 17 is placed on the support frame 1 Above, the pressure plate 3 presses the plane structure 8 of the box positioning frame; the pressure plate 3, the positioning plate 4 and the support frame 1 are fixed on the mounting plate 5 together; through the transition connecting frame 7, 8, this mechanism can be installed on the guide rail sliding sleeve 6 . Open the frame structure 16 of the box positioning frame, put the film-sealed box 13 on the support frame 1, the sealing film faces downward, and put down the frame structure 16 of the box positioning frame, due to the frame structure of the frame structure 16 of the box positioning frame, the The film-sealed box 13 is automatically positioned at the starting position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com