Tool apparatus, system and method of use

A technology of equipment and tools, applied in the field of tool equipment, systems and use, can solve problems such as difficulty in dismantling parts, damage to parts, and detachment of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] Example 1: Vehicle repair center

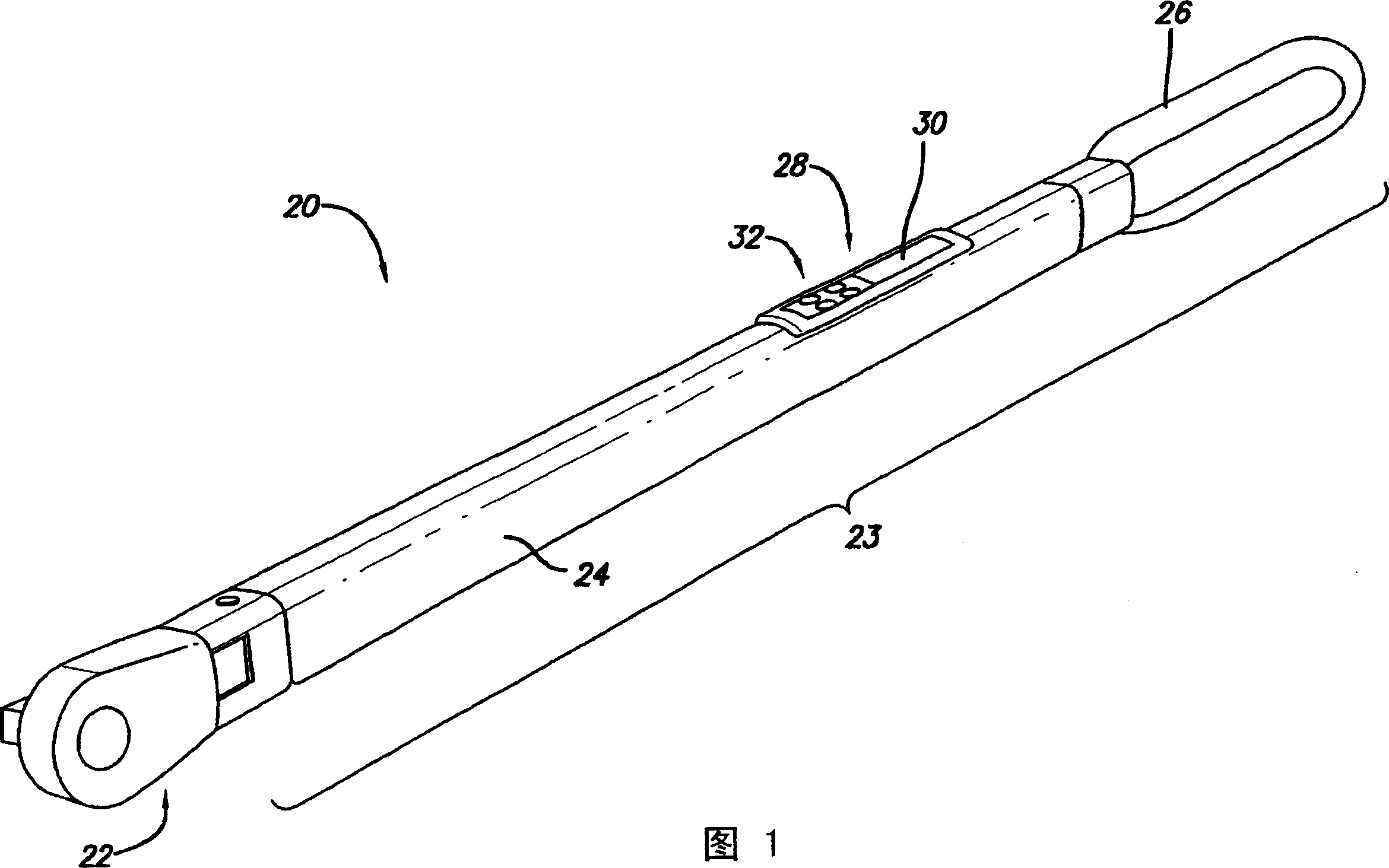

[0052] One embodiment of the system 112 is used for the installation of lug nuts on automobile wheels in the tire and wheel industry. The torque management system 112 provides the user with a manually operated electronic torque measuring tool 20 with a pneumatically driven power ratchet that is limited by torque. The user is provided with the ability to retrieve and maintain the required torque value of the lug nut from the torque value database (an embodiment of the technical specification database module 104) to develop into the original equipment manufacturer's technical specification.

[0053] The service representative of the tire and wheel industry tools and equipment enters the programmed torque setting value from the database. These settings are programmable or user-defined torque settings for the original equipment manufacturer (OEM). In this embodiment, the original equipment manufacturer (OEM) torque specifications are those p...

example 2

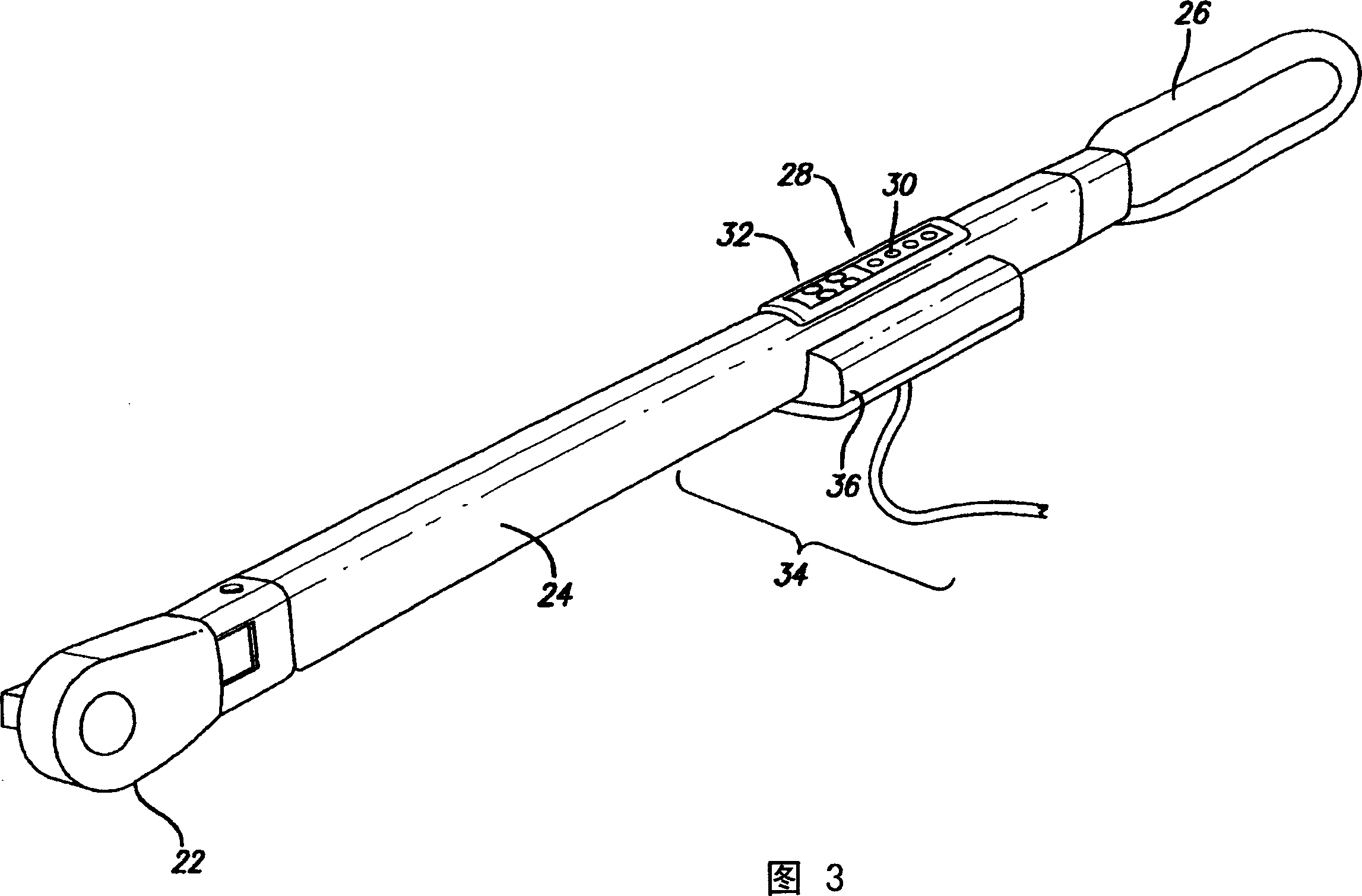

[0076] Example 2: Infrared communication path

[0077] The handheld device 30 and the workshop management system 22 communicate with each other. The technician selects the vehicle to be operated on from a pick list existing at the controller 28. After selecting from the pick list, the controller 46 queries its internal database for vehicles related to the repair order, or sends a request to the system 100 to query the technical specification database module 104 and retrieve and transmit the belt to each wheel. Technical specification for ear nut torque. Once the data is displayed, the technician can direct the technical specification to the infrared port on the tool 20 through the infrared communication path 34. After completing the torque operation of the lug nut, the technician can send the result of the operation back to the control device 28, so that the confirmation information and the repair order data can be sent back to the workshop management system 100 for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com