Thermosensitive head

A technology of thermal head and heating resistor, applied in the field of thermal head, can solve problems such as difficulty in reducing uneven printing density, inability to ensure expansion of common electrode area, complex external energy control, etc., so that printing density unevenness is not obvious Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

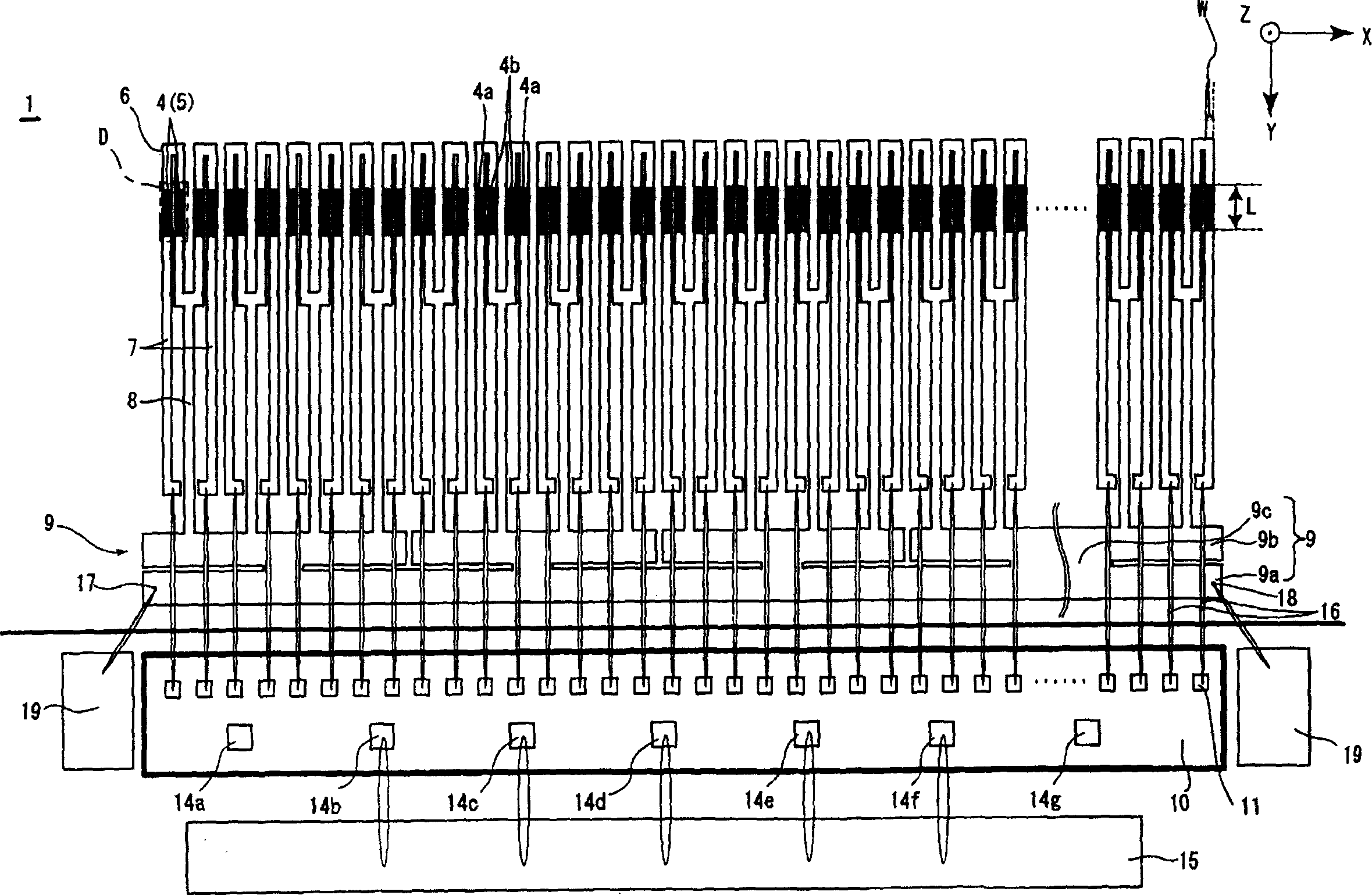

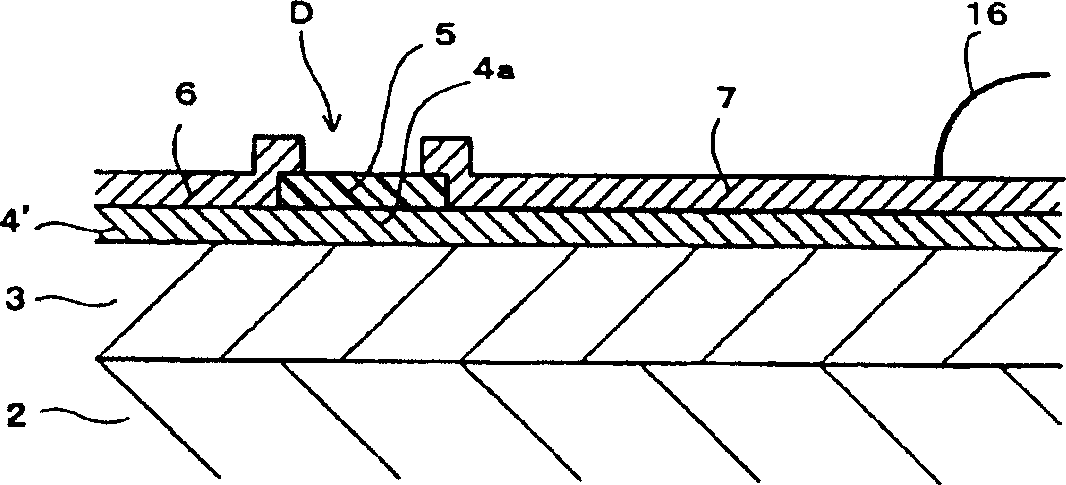

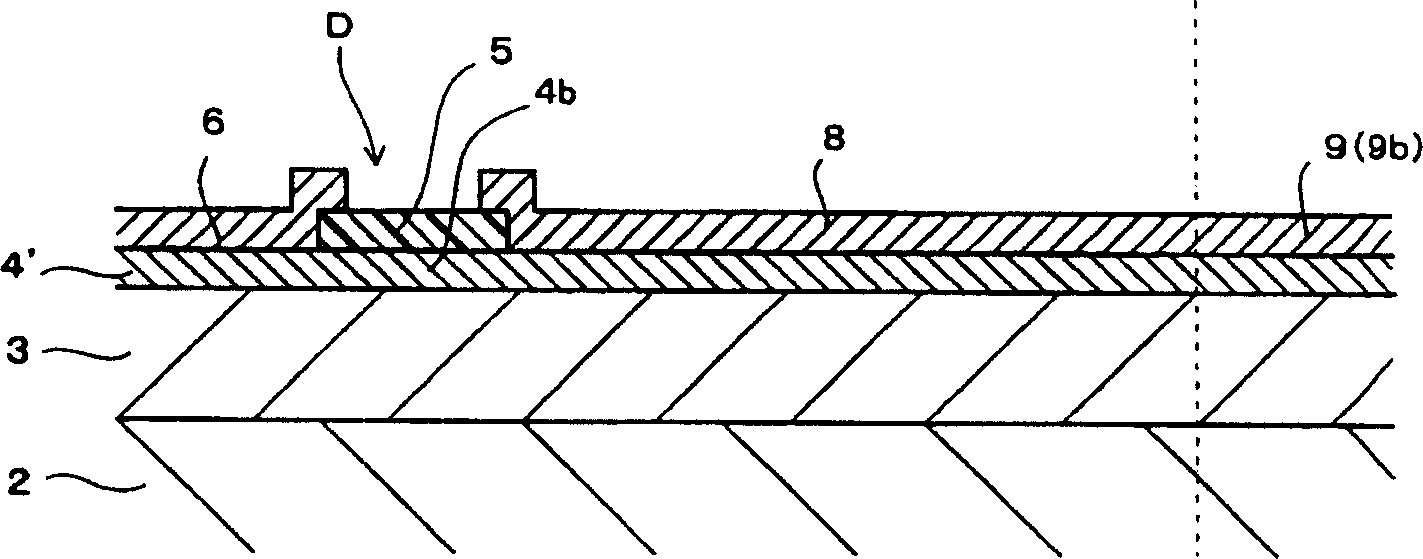

[0024] Figure 1 to Figure 3 A thermal head 1 according to an embodiment of the present invention is shown. In each figure, the X direction is the arrangement direction of the printed dots (and the extension direction (longitudinal direction) of the common line), the Y direction is the energization direction of the printed dots (and the width direction of the common line), and the Z direction is the thermal The stacking direction of each layer of the sensitive head.

[0025] The thermal head 1 has a heat storage layer 3 formed of, for example, a heat insulating material such as glass, on a substrate 2 made of Si, a ceramic material, a metal material, or the like, which is excellent in heat dissipation. The heating resistors 4 are arranged in a row at a slight interval in the direction. Each heating resistor 4 is made of Ta 2 N or Ta-SiO 2 A part of the resistance layer 4' formed over the entire surface of the heat storage layer 3 by using a cermet material such as the like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com