Anti-counterfeiting material

A technology of organic materials and patterns, applied in fiber raw material processing, textiles and papermaking, non-fiber pulp addition, etc., can solve the problems of not being able to change from red to black, limited selection of pattern transformation, and inability to disappear, etc., achieving obvious anti-counterfeiting effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

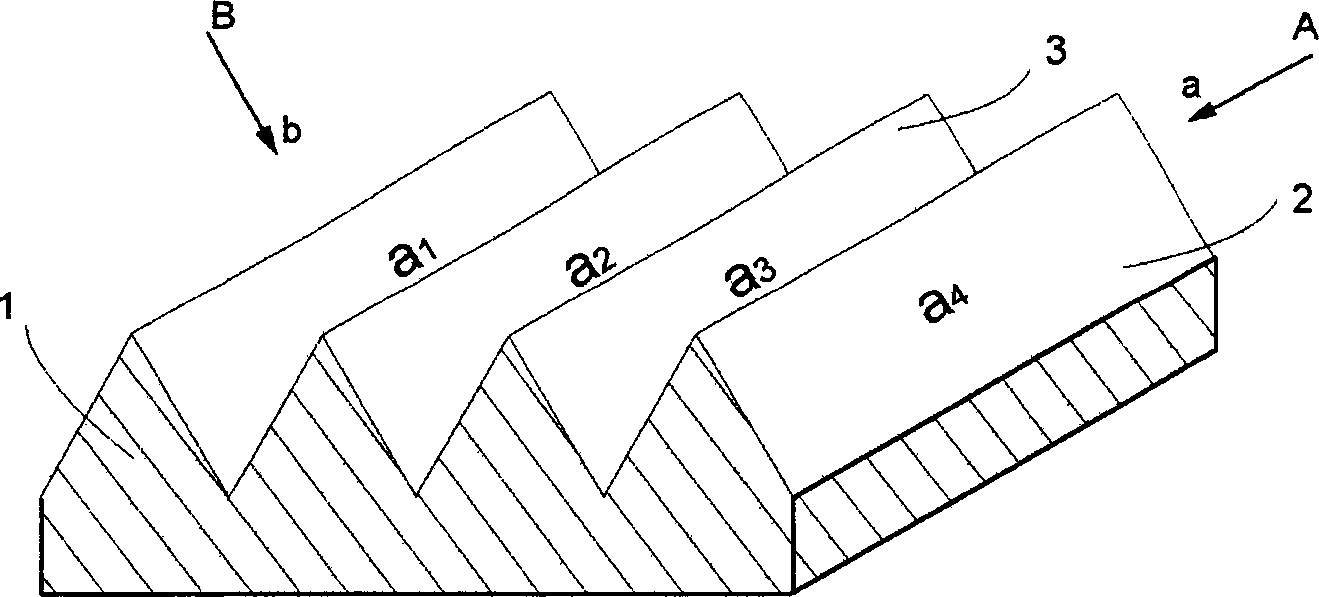

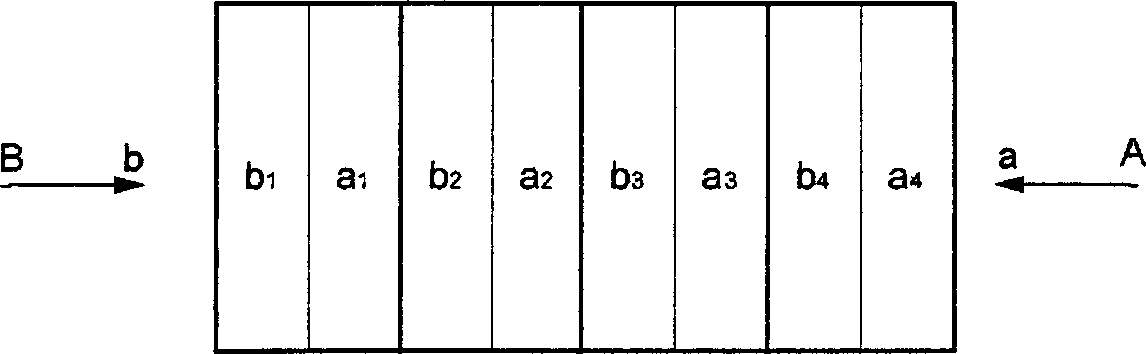

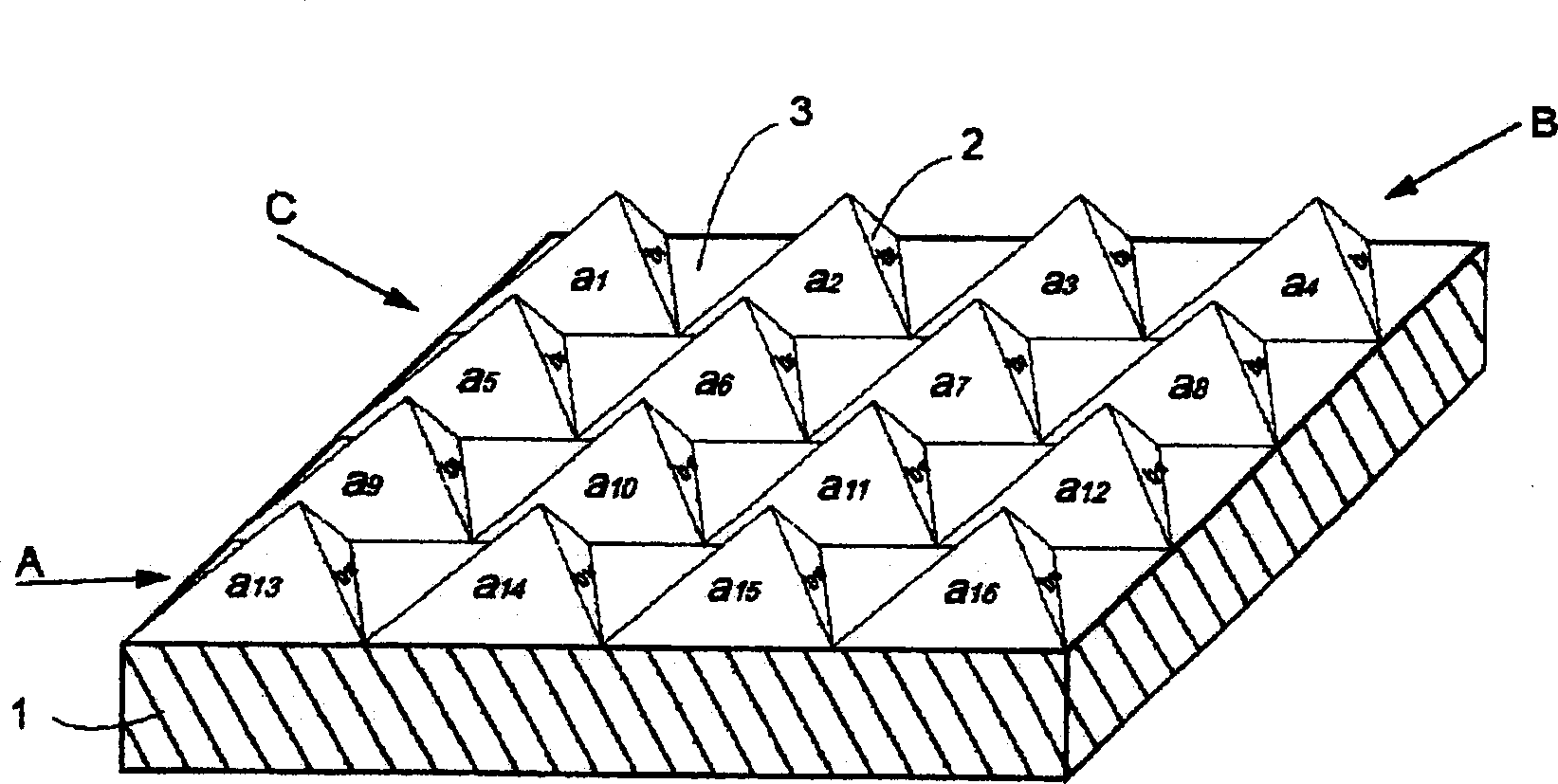

[0042] Figure 1a to Figure 3a Listed are three embodiments in which the concave-convex shielding structure 2 of the anti-counterfeiting material 1 of the present invention has different three-dimensional structures, and the concave-convex structures on the surface of these materials are used for shielding.

[0043] Figure 1a The concave-convex occlusion structure 2 shown is a three-dimensional two-sided cone. The figure shows multiple two-sided cones of the same size side by side, with a single concave-convex structure image. Each two-sided cone is equivalent to a occlusion element and a visible surface It is composed of many shading elements facing the same micro-surface. In Figure 1, the micro-surfaces a1, a2, a3, and a4 facing the same direction and can be printed with the same or different imprints constitute a visible surface; The microsurfaces b1, b2, b3, and b4 of different imprints constitute another visible surface. Two characteristic patterns A and B are respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com