Method for control of the curl of paper in the treatment of surface-sized paper, and finishing section of a paper machine

A surface sizing and paper machine technology, which is applied in the field of paper curl control and paper machine finishing when processing surface sized paper, can solve problems such as web breakage and low web strength, increase drying power, and improve progress performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

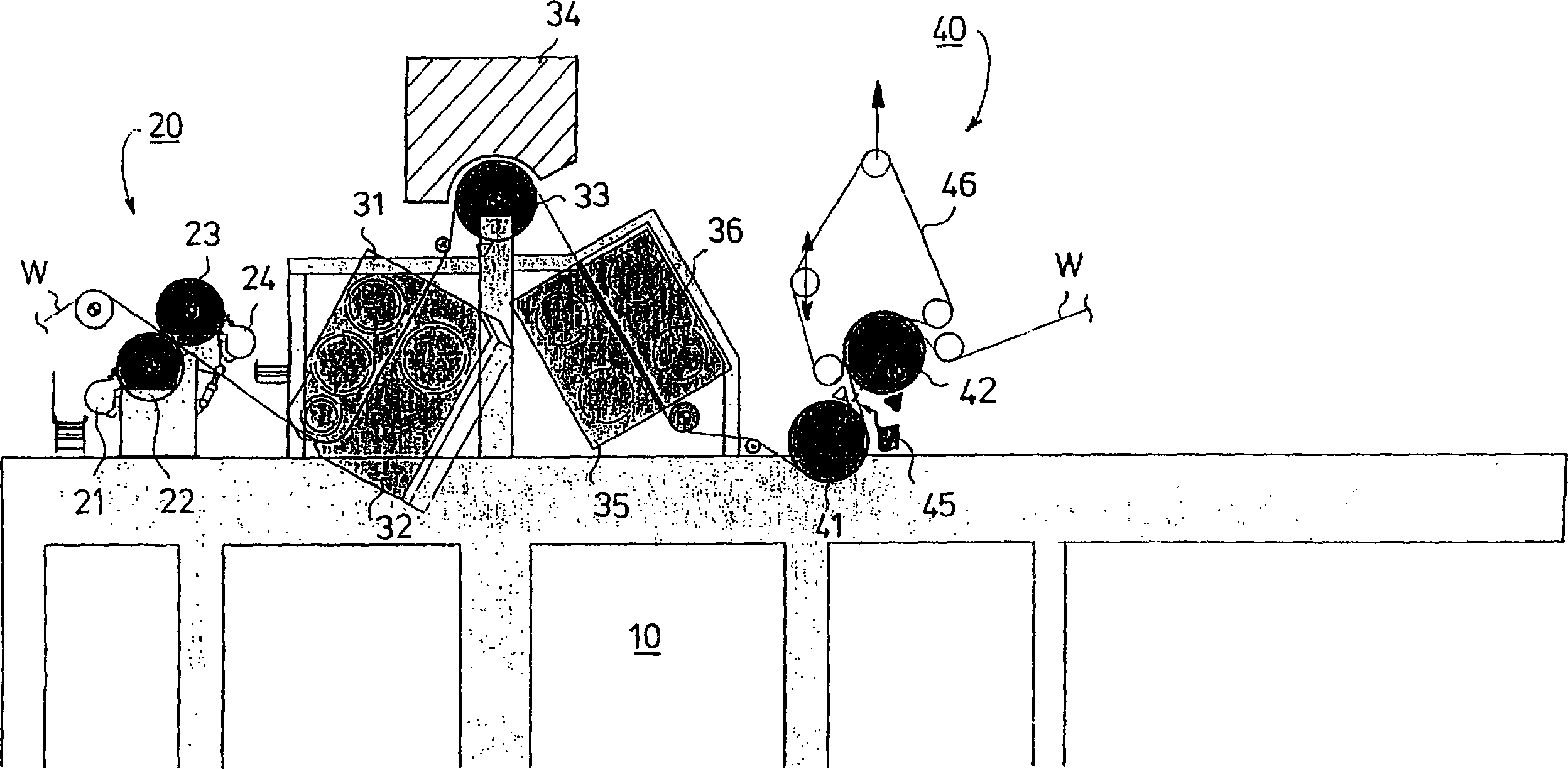

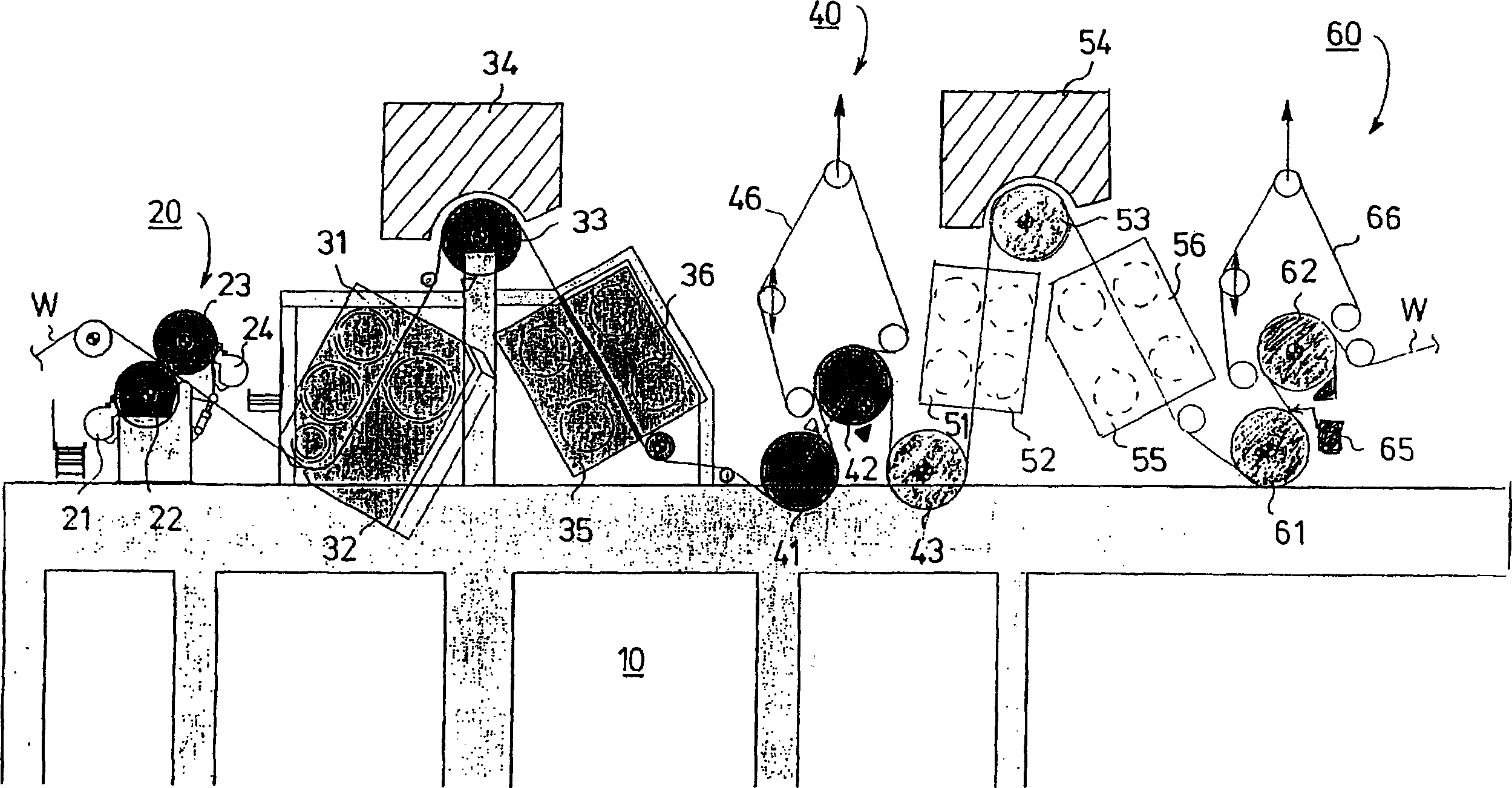

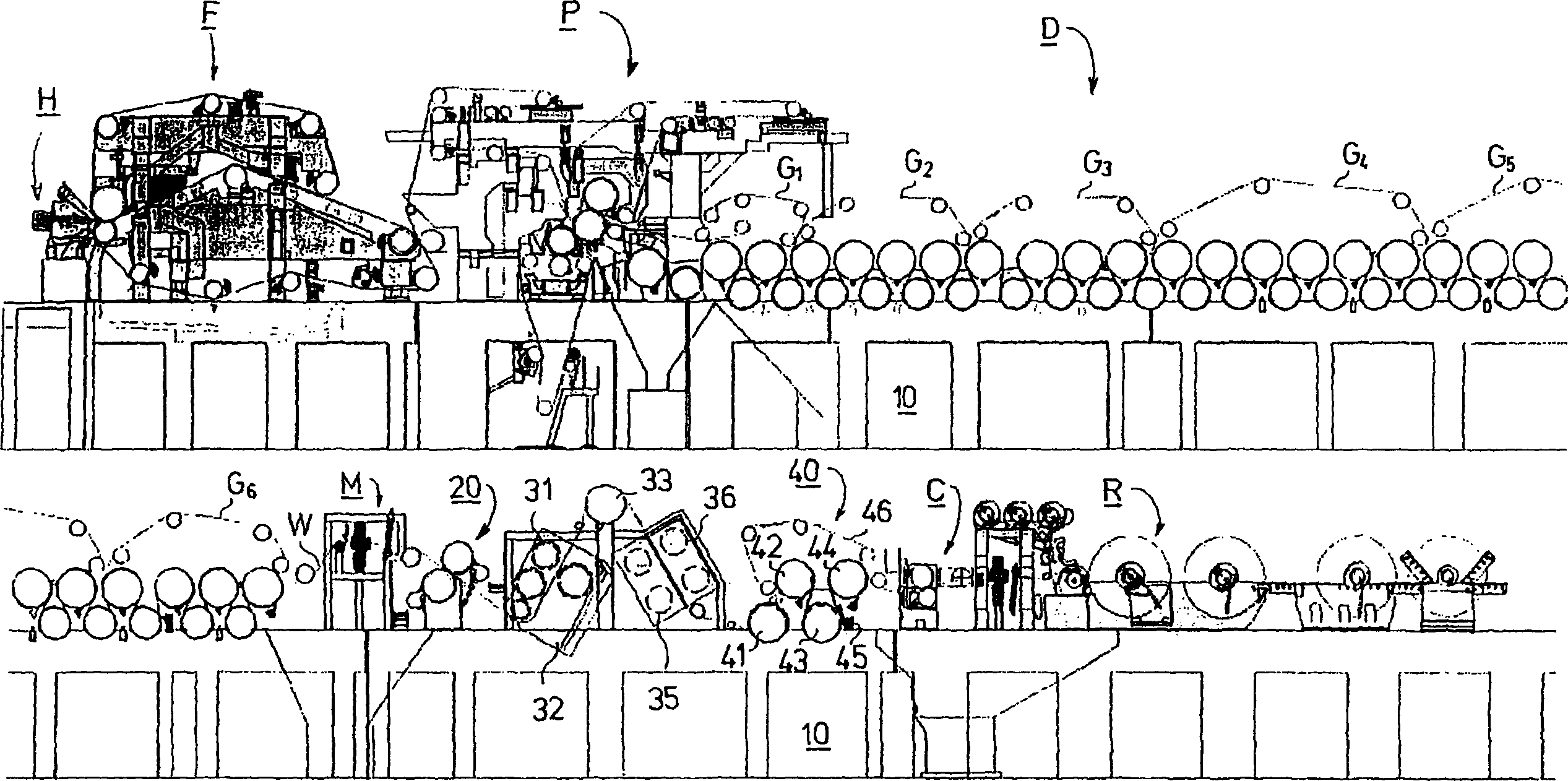

[0048] exist figure 1 Up to FIG. 8 , the same reference numerals are used to denote parts corresponding to each other unless otherwise specified.

[0049] figure 1 is a schematic illustration of an embodiment of the invention in which the web W passes from the front dryer group section (not shown) to the surface sizing section 20, the web W on both sides in the nip between rolls 22, 23 Surface sizing is carried out in which both sides of the web W are wetted by the aqueous surface sizing agent. In this way, a paper web which is dried asymmetrically and tends to curl in the front dryer bank section is treated such that the internal stresses of the paper web are relieved or at least weakened. The surface sizing agent is transferred from the supply device 21 , 24 onto the surface sizing rollers 22 , 23 . The paper web W is then dried in a non-contact manner; the paper web W is first dried by air web drying devices 31, 32 placed on both sides of the paper web. The web then pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com