Spray nozzle

A technology of nozzles and injection ports, which is applied in the field of nozzles and can solve problems such as turbulent entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

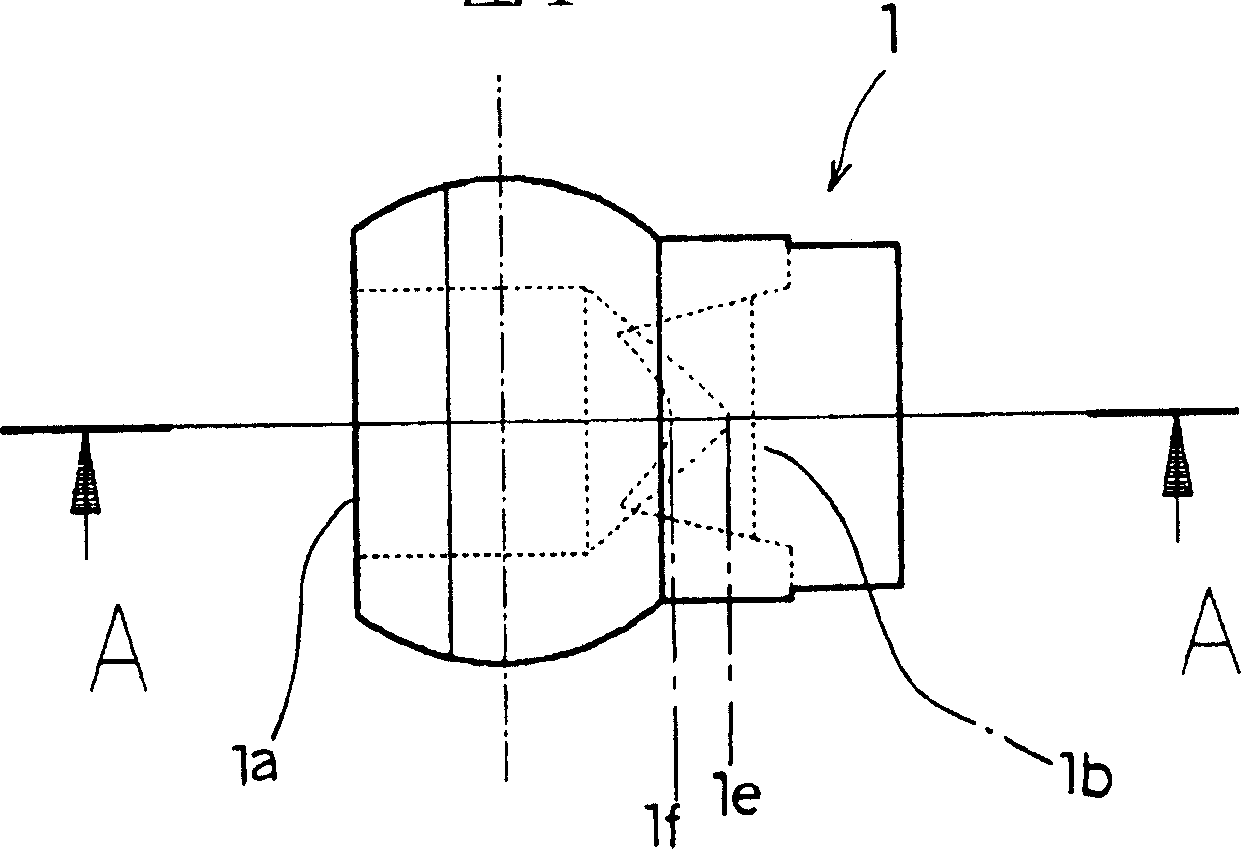

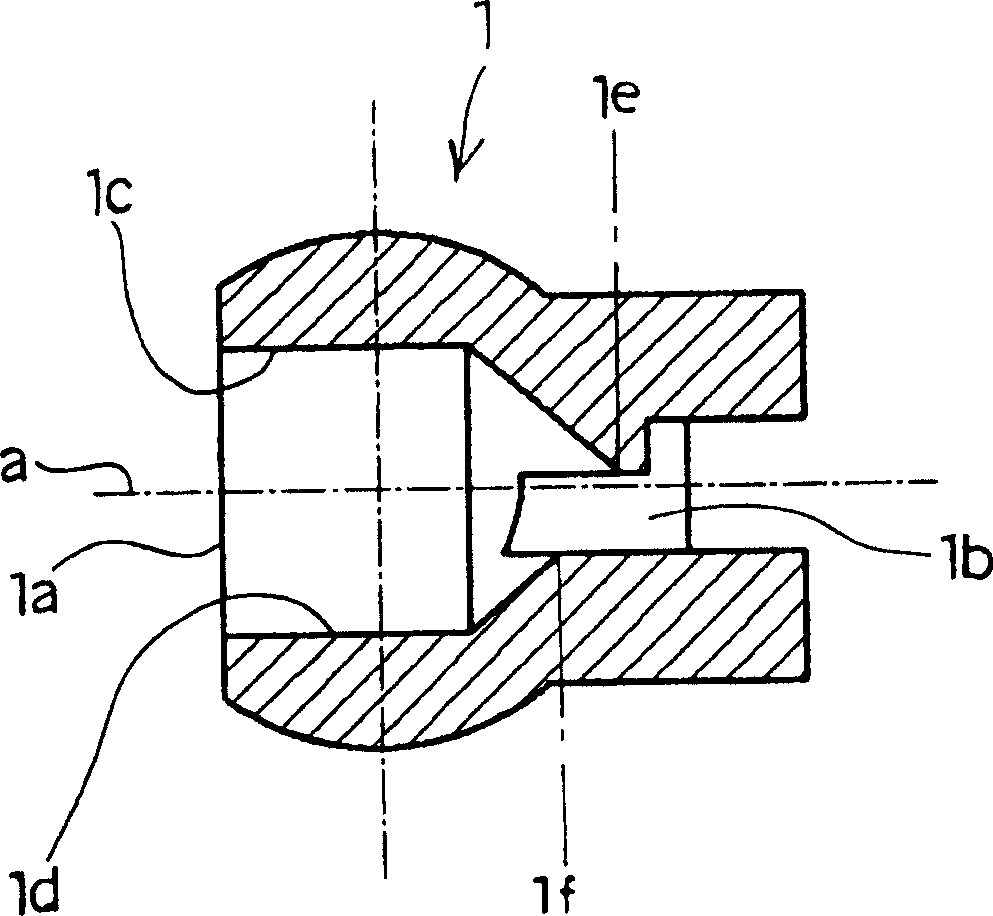

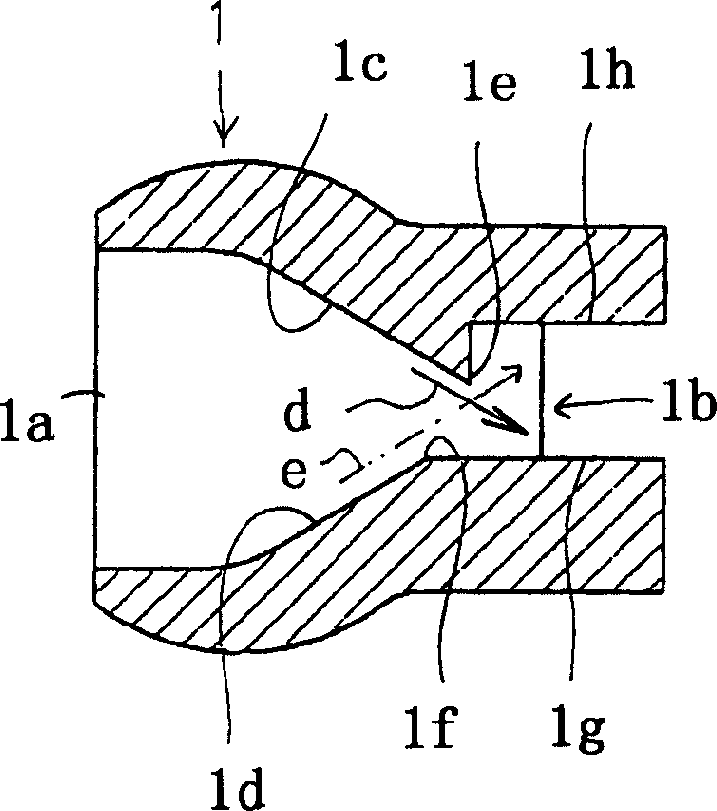

[0019] The nozzle 1 according to the present invention is, for example, a washer nozzle for spraying a washer fluid onto a windshield of an automobile. Such as figure 1 and figure 2 As shown, in the flow path reaching the supply port 1a and the horizontally formed ejection port 1b in the nozzle 1, the cross-sectional area of the flow path is gradually reduced to form a structure consisting of upper and lower inner peripheral wall surfaces 1c and 1d reaching the ejection port. of the cone. The upper position 1e and the lower position 1f of the injection port-side ends of the tapered portions 1c and 1d are formed to be offset from each other in the direction of the axis a of the flow path. In the illustrated embodiment, the position 1e of the upper jet port side end is as follows figure 2 As shown, it is disposed closer to the injection port 1b side with respect to the position 1f of the lower side end portion on the injection port side.

[0020] As for the positions 1e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com