Sewing machine

A technology for sewing machines and actuating rods, which is applied in the field of sewing machines, can solve the problems of laborious reinsertion of the actuating rods, achieve the effect of eliminating the locking effect, reducing the requirements for locking the swing axis, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

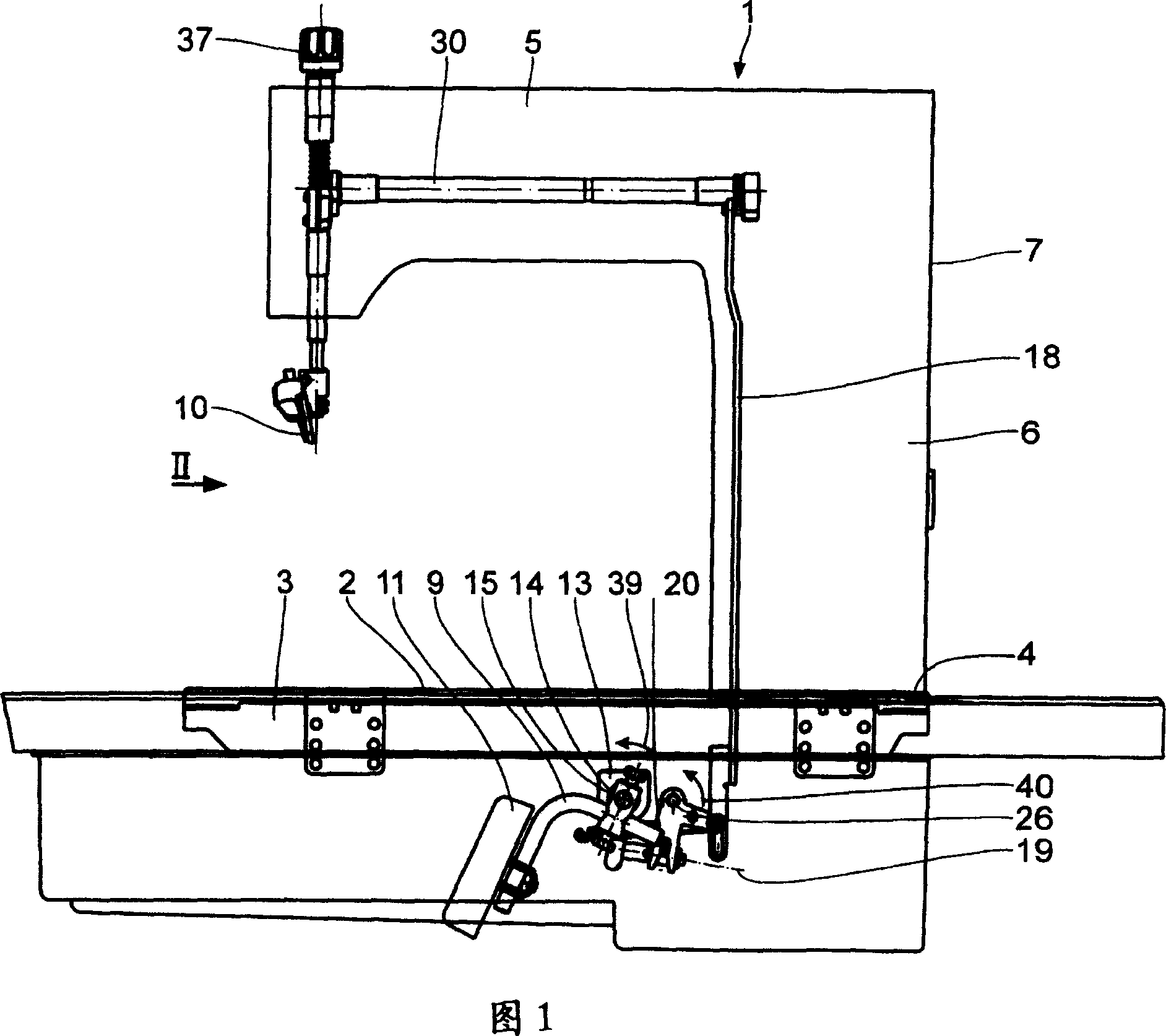

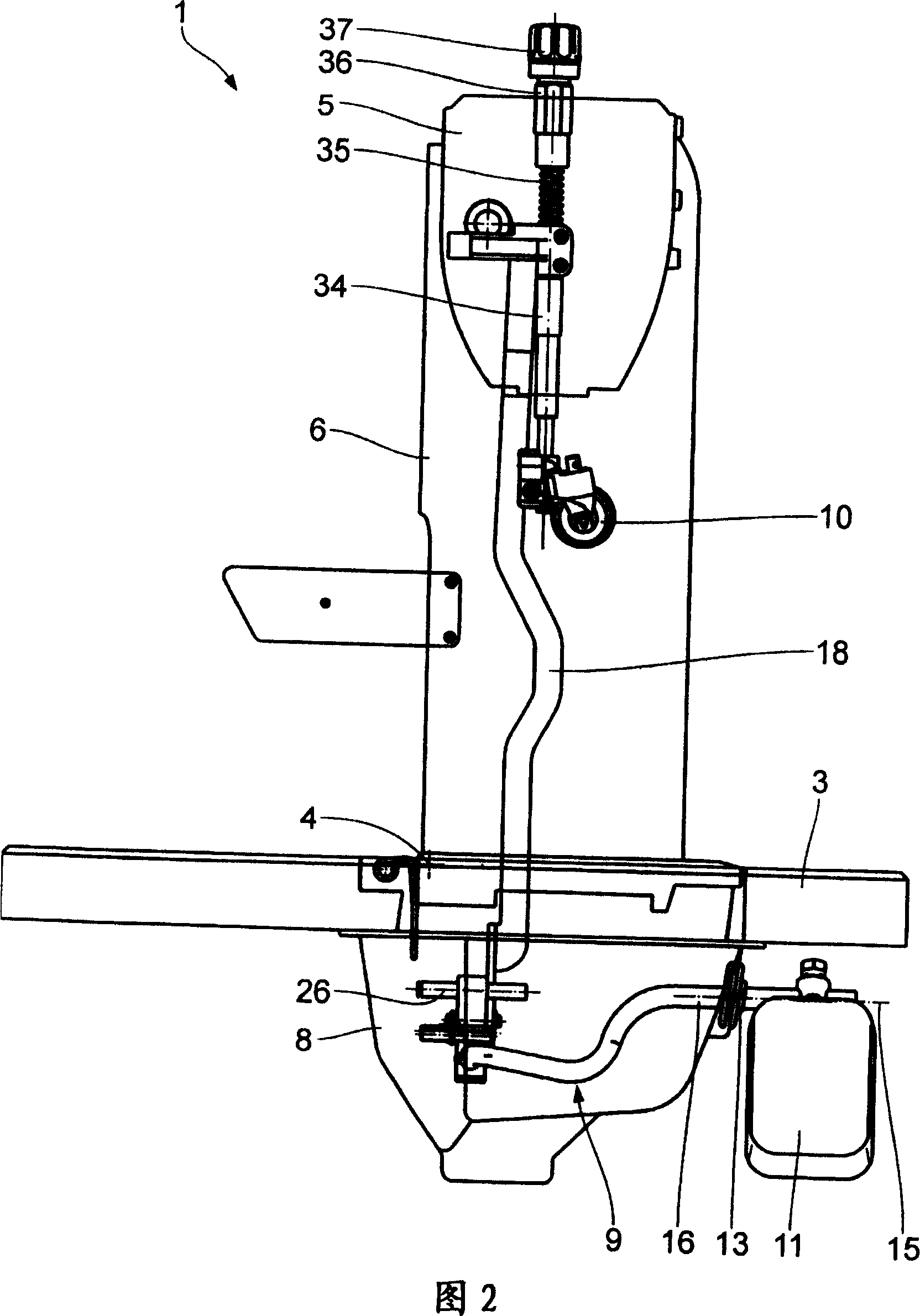

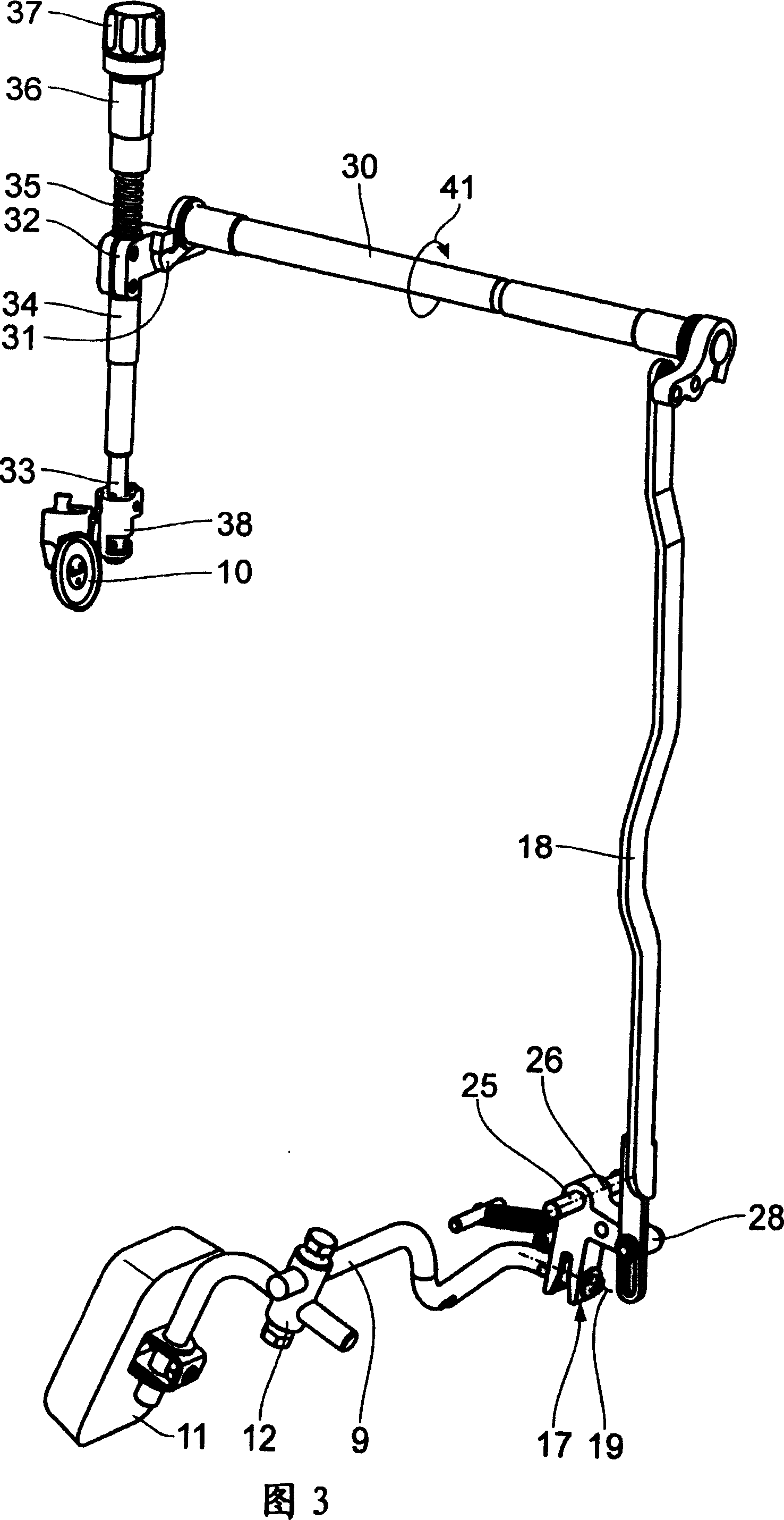

[0026] The sewing machine 1 has a base plate 2 on which—possibly also via intermediate components—the sewing material to be sewn can be placed. The base plate 2 rests on the carrier plate 3 . The base plate 2 can be pivoted about the pivot axis 4 relative to the support plate 3 via a pivot bearing (not shown in detail). The tilting axis 4 extends perpendicular to the projection plane of FIG. 2 and is located in the vicinity of the bearing area of the base plate 2 on the bearing plate 3 on the side facing away from the user, in other words on the left side of the sewing machine 1 in FIG. 2 .

[0027] The sewing machine 1 has a top arm 5 and a column 6 connecting the base plate 2 and the top arm 5 . Below the support plate 3 , an actuating lever 9 emerges from a housing 7 of the sewing machine 1 , the housing being formed here by an oil sump 8 . The actuating lever 9 serves to raise a sewing tool, such as a roller foot 10 , of the sewing machine 1 . This raising to remove o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com