Process for producing alloy slab for rare-earth sintered magnet, alloy slab for rare-earth sintered magnet and rare-earth sintered magnet

A technology of sintered magnets and a manufacturing method, which is applied in the directions of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of not being able to obtain alloy castings and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0156] An alloy of 31.5% by mass of neodymium, 1.04% by mass of boron, and the balance of iron is mixed with neodymium metal, boron-iron alloy and iron, and melted in a high-frequency melting furnace in an argon atmosphere. In the state where the alloy is completely melted, after standing still for a while, the oxide of neodymium will float as slag, and then remove the slag.

[0157] Next, the obtained alloy solution having a temperature of 1500° C. was supplied to a single roll by the strip casting method, and cooled at a peripheral speed shown in Table 1 to produce an alloy cast sheet having a thickness of 0.2 mm. At this time, a tundish made of refractory ceramics was used. On the other hand, for iron rollers, Ra adjusted to 1 μm was used.

[0158] The average crystal grain size, the average interval r of R-rich regions, and the total volume ratio of chilled grains and fine structures of the obtained alloy slabs were measured. The results are shown in Table 1.

[0159] Nex...

reference example 2 and 3

[0161] Except that the thickness of the alloy cast pieces was 0.3 mm and 0.4 mm, alloy cast pieces and sintered magnets were produced in the same manner as in Reference Example 1, and various measurements were performed. The results are shown in Table 1. In addition, the alloy microstructure photos of the alloy cast sheet obtained in Reference Example 3 were detached from the cooling roll and perpendicular to the moving direction (C section with respect to the direction of roll rotation) through an optical microscope and a polarizing microscope, respectively. Figure 13 shows.

[0162] Refer to Comparative Examples 1 and 2

[0163] After melting the alloy, do not stand still, remove the slag, and preheat the tundish, and use a copper roll with Ra of 7 μm, except that the thickness of the alloy cast piece is made 0.2 mm, 0.7 mm, the same as Reference Example 1 Operation, production of alloy castings, sintered magnets, and various measurements. The results are shown in Table 1...

Embodiment 1

[0170] An alloy of 31.5% by mass of neodymium, 1.0% by mass of boron and the balance of iron is mixed with neodymium metal, boron-iron alloy and iron, and melted in a high-frequency melting furnace in an argon atmosphere.

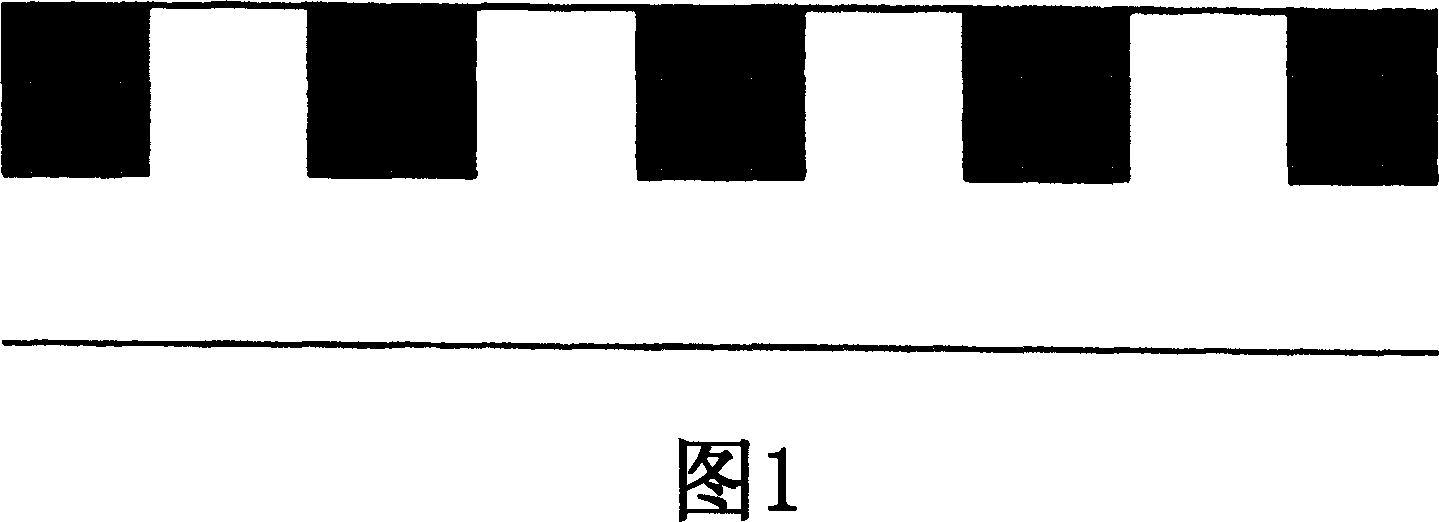

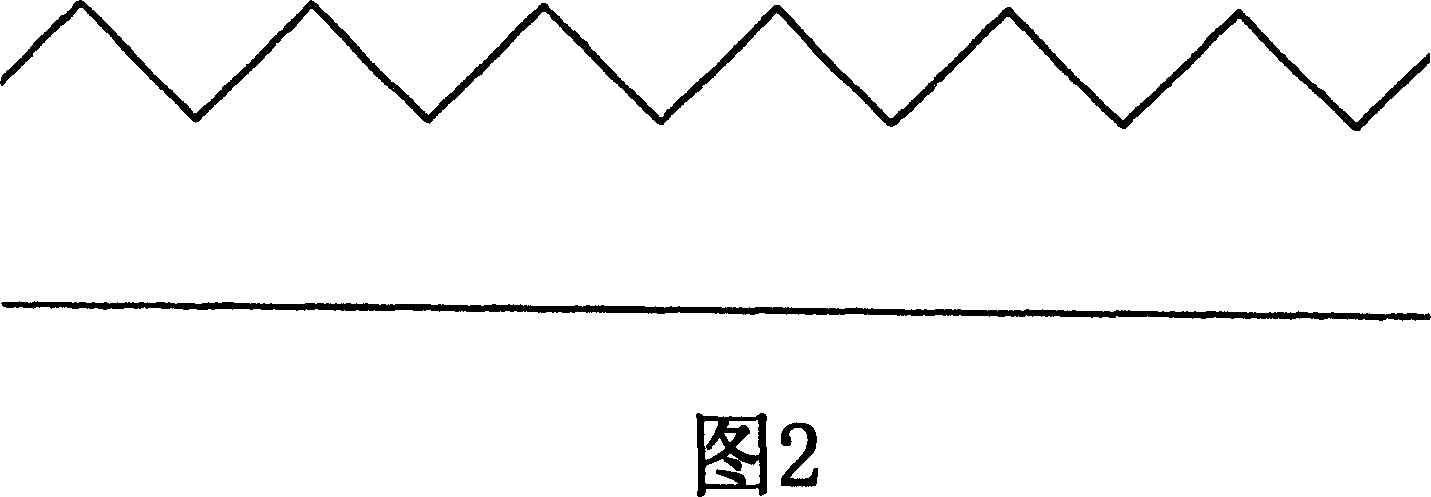

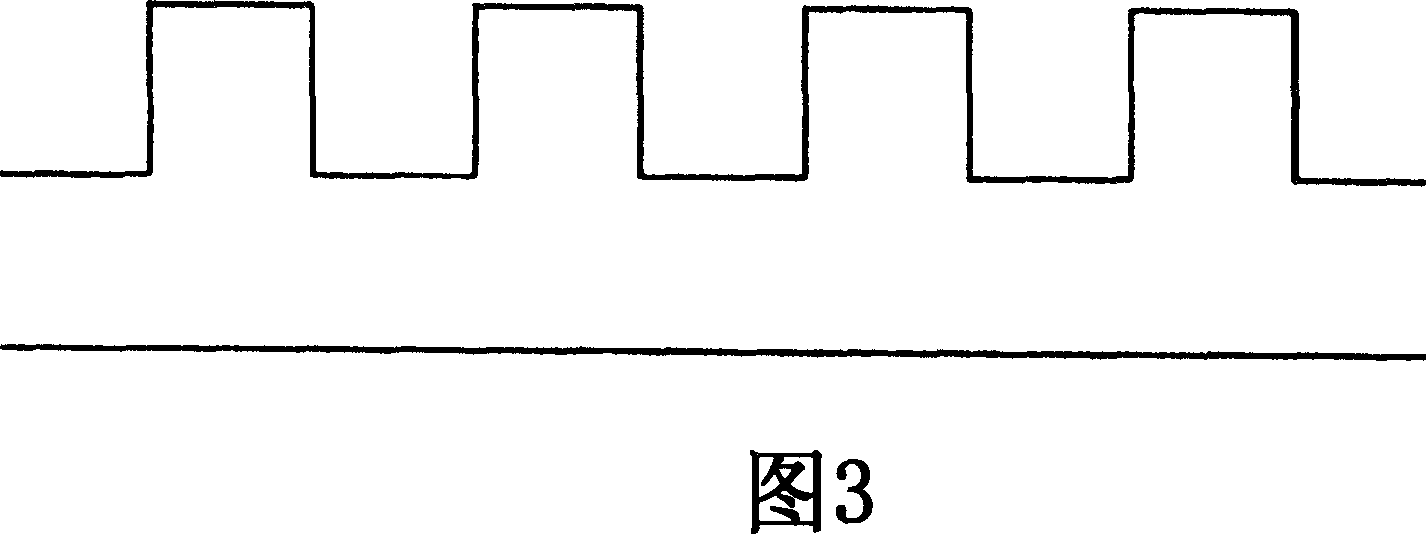

[0171] Next, the obtained alloy solution at a temperature of 1500° C. was supplied to a single roll through a tundish for strip casting, cooled and solidified at a peripheral speed of 0.8 m / sec, and an alloy cast sheet with a thickness of 0.3 to 0.4 mm was produced. The cooling roll used is that, on the surface of the cooling roll, the solidification nucleation generation part having the protruding part of the cross-sectional shape shown in FIG. A cooling roll made of copper having a surface pattern shown in FIG. 4 . The solidification nucleation generation part is formed at the top of the peak of the cross section, and the linear solidification nucleation suppression part containing the argon atmosphere is formed at the valley part. The interval at the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap