Air transport device for fuel cell engine at atmospheric operation

An air conveying device, fuel cell technology, applied in the direction of fuel cells, fuel cell additives, electrical components, etc., can solve the problems that there is no way to meet the flat and tiled installation requirements of fuel cell engines, and the diameter of the fan blower is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

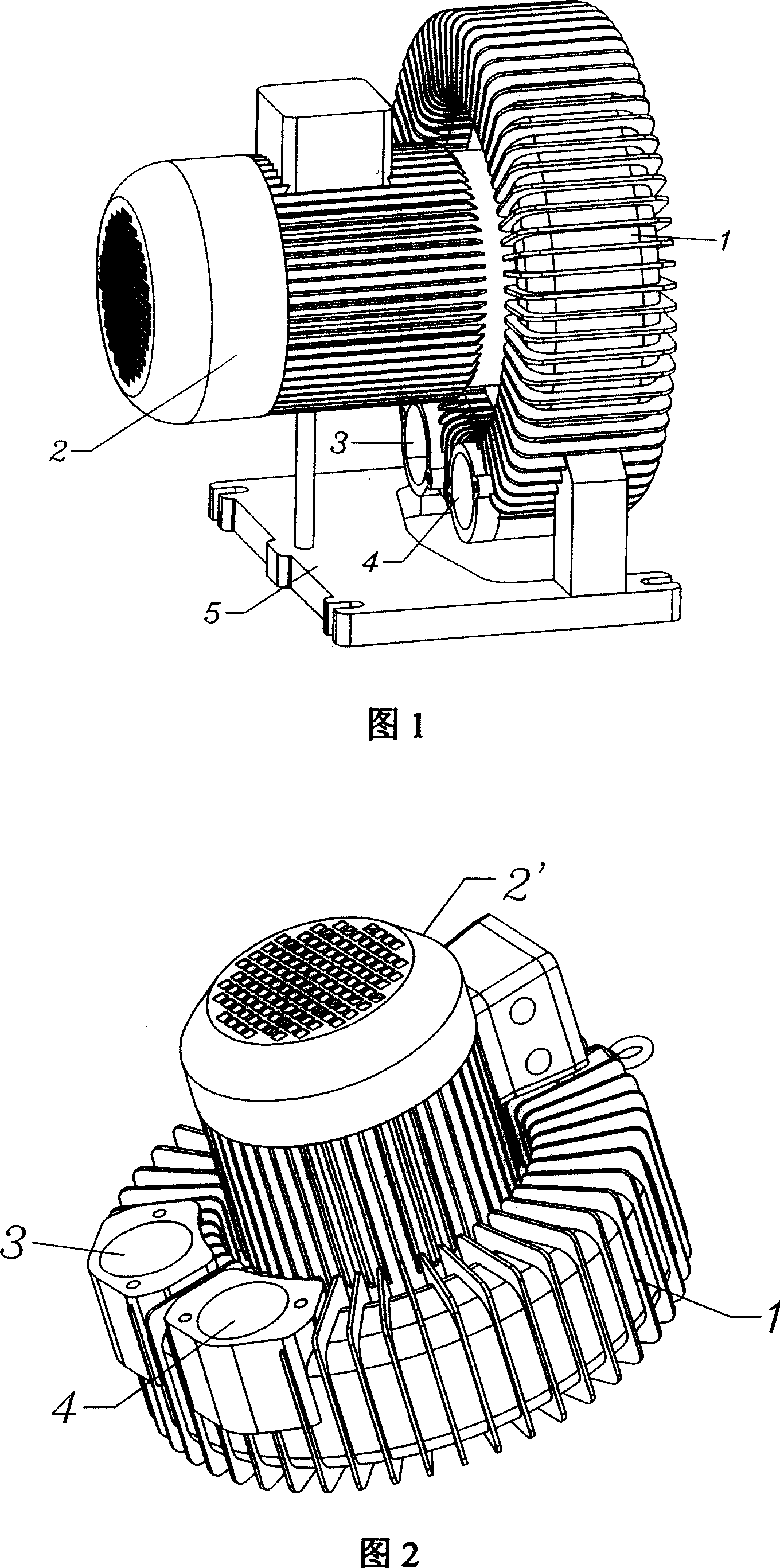

[0036] As shown in Fig. 2 and Fig. 3, a fuel cell engine air conveying device operated under normal pressure of 50 kilowatts comprises a flat motor 2' (diameter φ170mm), wind drum 1 (diameter φ360mm), and the motor 2' is designed On one end face of the air drum 1, and the rotation axis of the motor 2' is perpendicular to the air drum 1, the flattened height of the whole air conveying device is 280mm, and the air suction port 3 and the air outlet 4 are arranged on the air drum 1, The air suction port 3 and the air outlet 4 are arranged on the motor side end face of the wind drum 1, and the air suction port 3, the air outlet 4 are arranged axially with the air drum 1; and three evenly arranged installation holes 6 are included. 6 is arranged on the other end face of the wind drum 1, and is arranged axially with the wind drum 1; the wind drum 1 is directly installed as a mounting base, and the end face of the wind drum 1 is parallel to the ground.

Embodiment 2

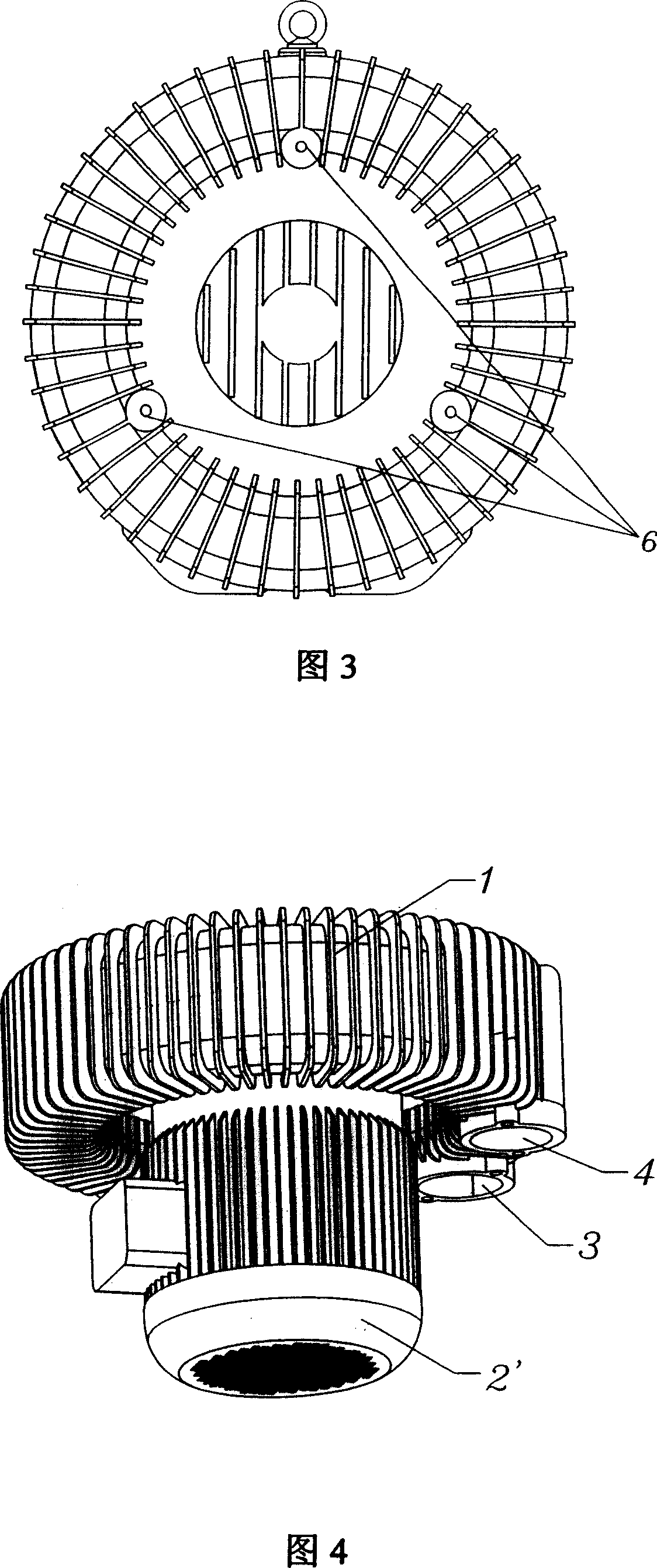

[0038] As shown in Figure 4, a 50 kW fuel cell engine air conveying device operated at normal pressure includes a flat motor 2 (diameter φ170mm), wind drum 1 (diameter φ360mm), and the motor 2' is located on the wind drum 1 One side end face of the motor 2', and the rotation axis of the motor 2' is perpendicular to the air drum 1, the flattened height of the whole air conveying device is 280mm, and the air drum 1 is provided with an air suction port 3 and an air outlet 4, and the air suction port 3 1. The air outlet 4 is arranged on the motor side end face of the air drum 1, and the air suction port 3, the air outlet 4 and the air drum 1 are axially arranged; five evenly arranged installation holes 6 are also included, and the installation holes 6 are arranged on the motor side. 2', and is axially arranged with the motor 2'; the motor 2' is directly installed as a mounting base, and the rotation axis of the motor is perpendicular to the ground.

Embodiment 3

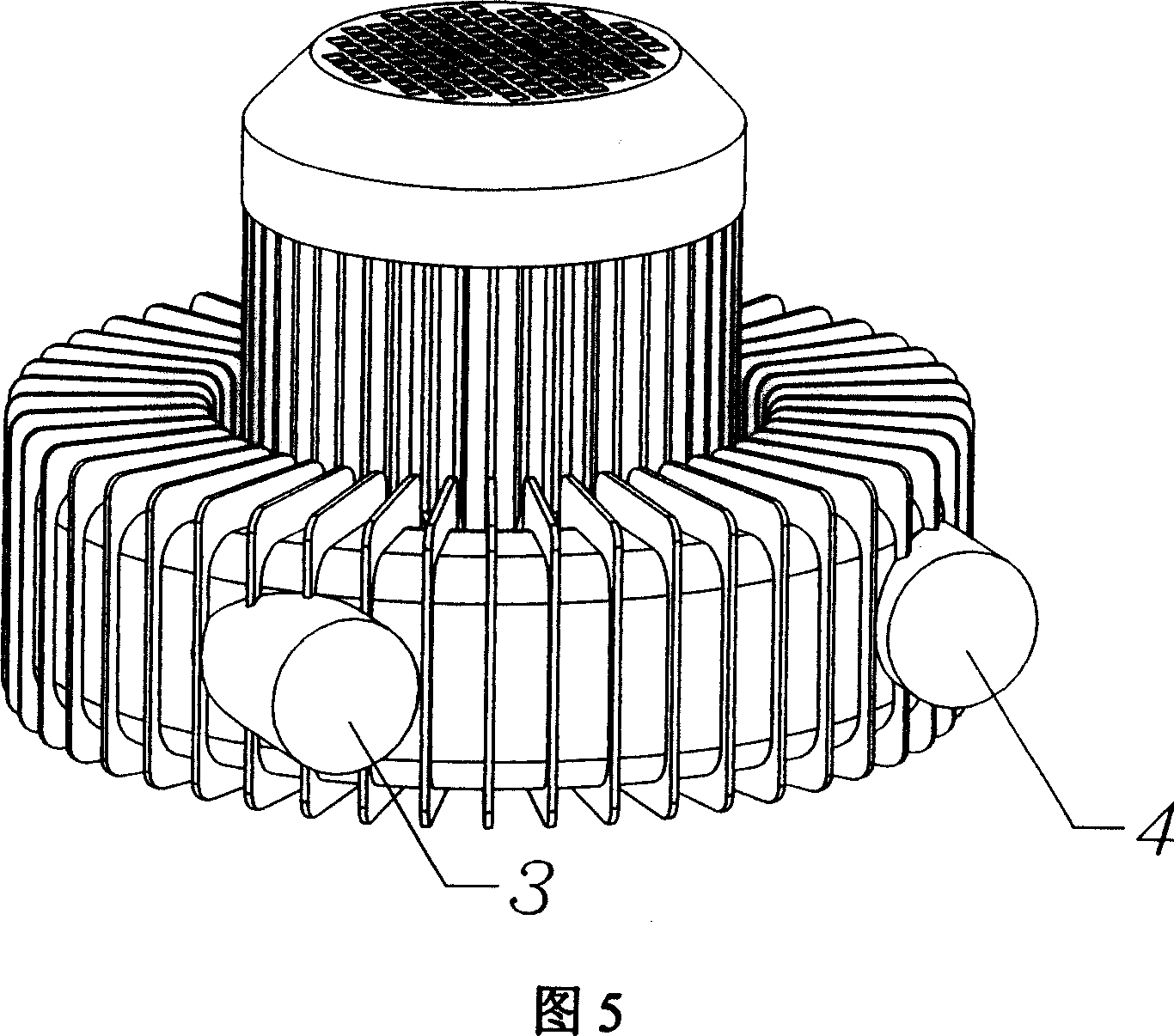

[0040] As shown in Figure 5, a kind of fuel cell engine air conveying device of 50 kilowatts normal pressure operation, the air suction port 3, the air outlet 4 of this device are arranged on the circumferential surface of the air drum 1, and the air suction port 3, the air outlet 4 It is arranged radially with the wind drum 1; other structures are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com