Quick-pour can

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] 1. Detailed Description of the Preferred Embodiment Figures

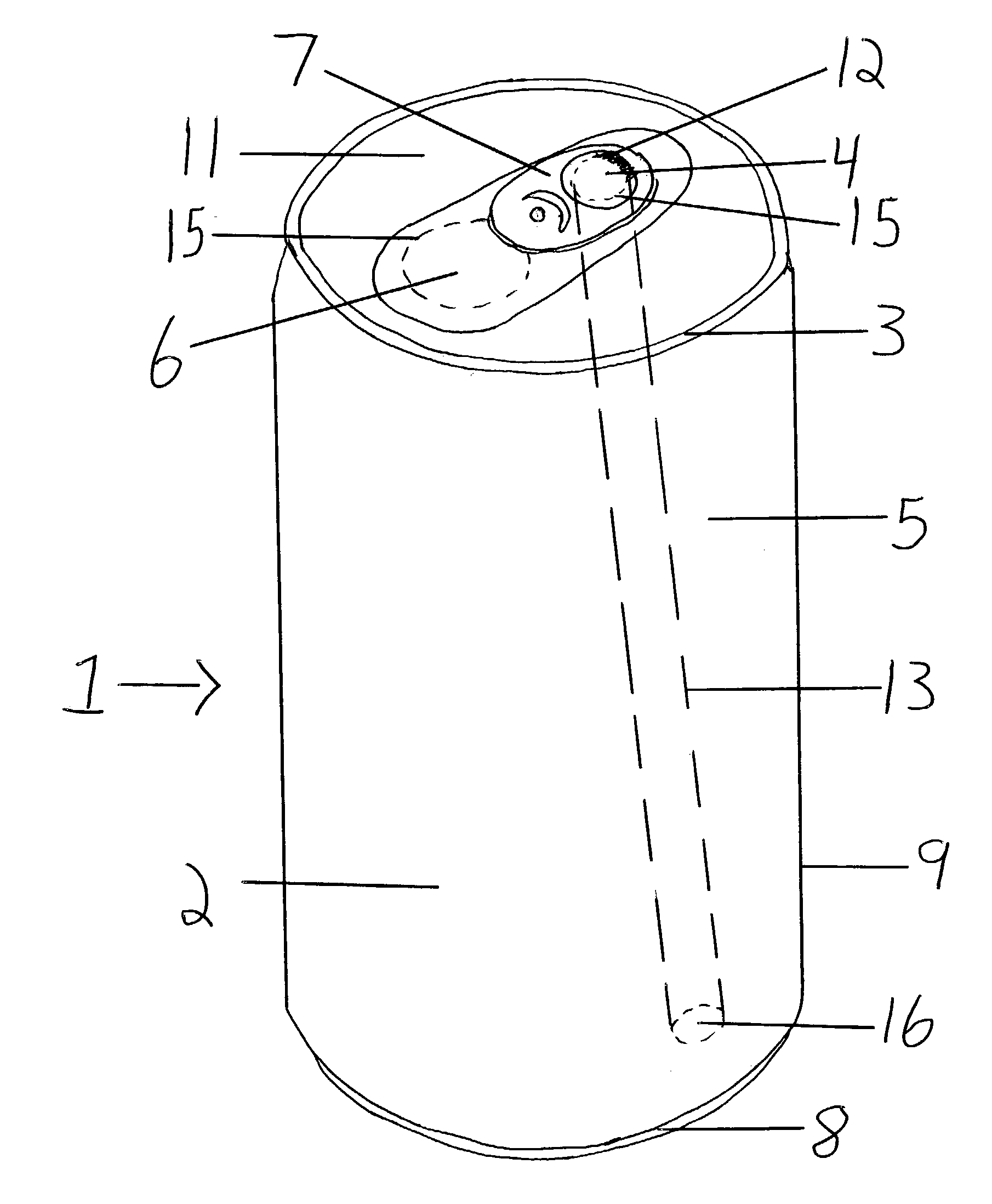

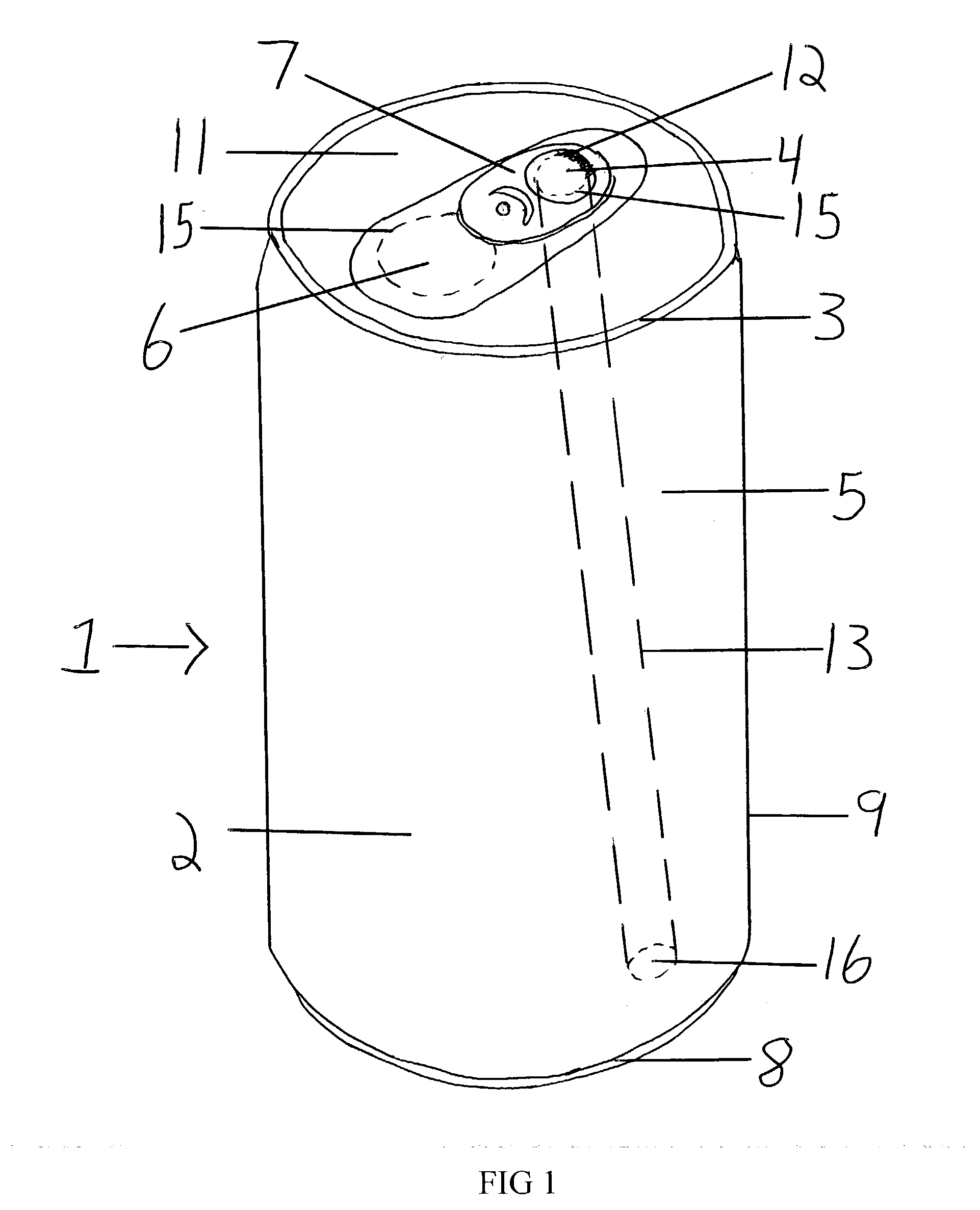

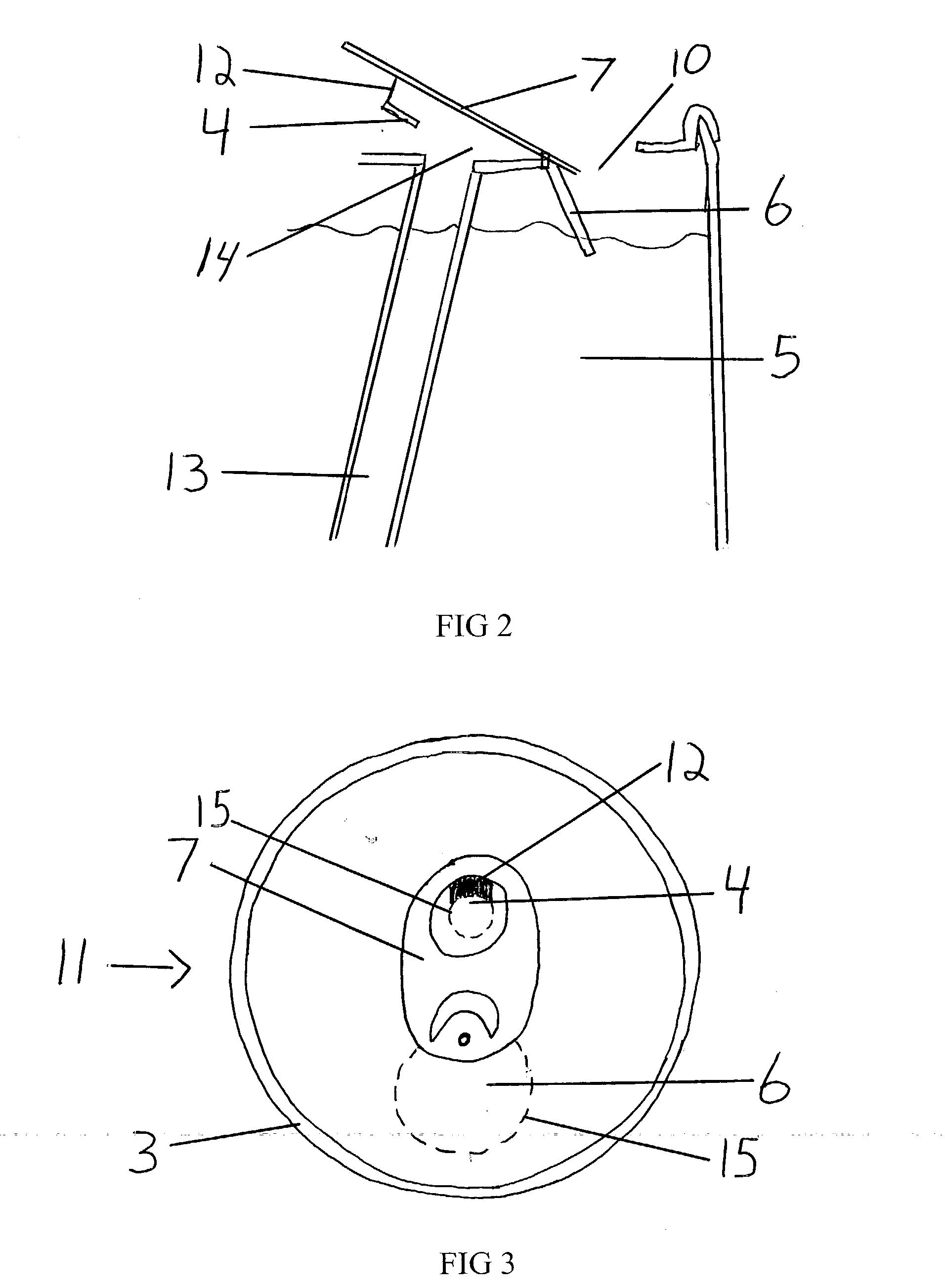

[0047] A typical embodiment of the present invention is illustrated in FIGS. 1 through 4. Referring to FIGS. 1 and 3, a dual-aperture beverage container 1 and a container top 11 are shown respectively. In the main embodiment, a container 2 consists of a container sidewall 9 that wraps around to form a hollow cylinder. The container sidewall 9 is made of metal and is effectively closed on both open ends so that it can completely seal the beverage inside. On top of the container sidewall 9 is connected the container top 11, while the bottom is sealed off with a container bottom 8. Like the container sidewall 9, the container top 11 and container bottom 8 are both made of metal. The container top 11 contains a pouring scored section 6, a tab 7, a venting scored portion 4, a container rim 3, a connecting metal 12, and a hollow venting tube 13. The container rim 3 is simply the circumference of the container top 11, securi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap