Vehicle seat incorporating a seat back panel

a seat back and vehicle seat technology, applied in the field of vehicle seat back incorporating a seat back panel, can solve the problems of reducing weight components that must still provide structural rigidity, difficult to meet the above-mentioned design goals, and difficult to perform maintenance on seat assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

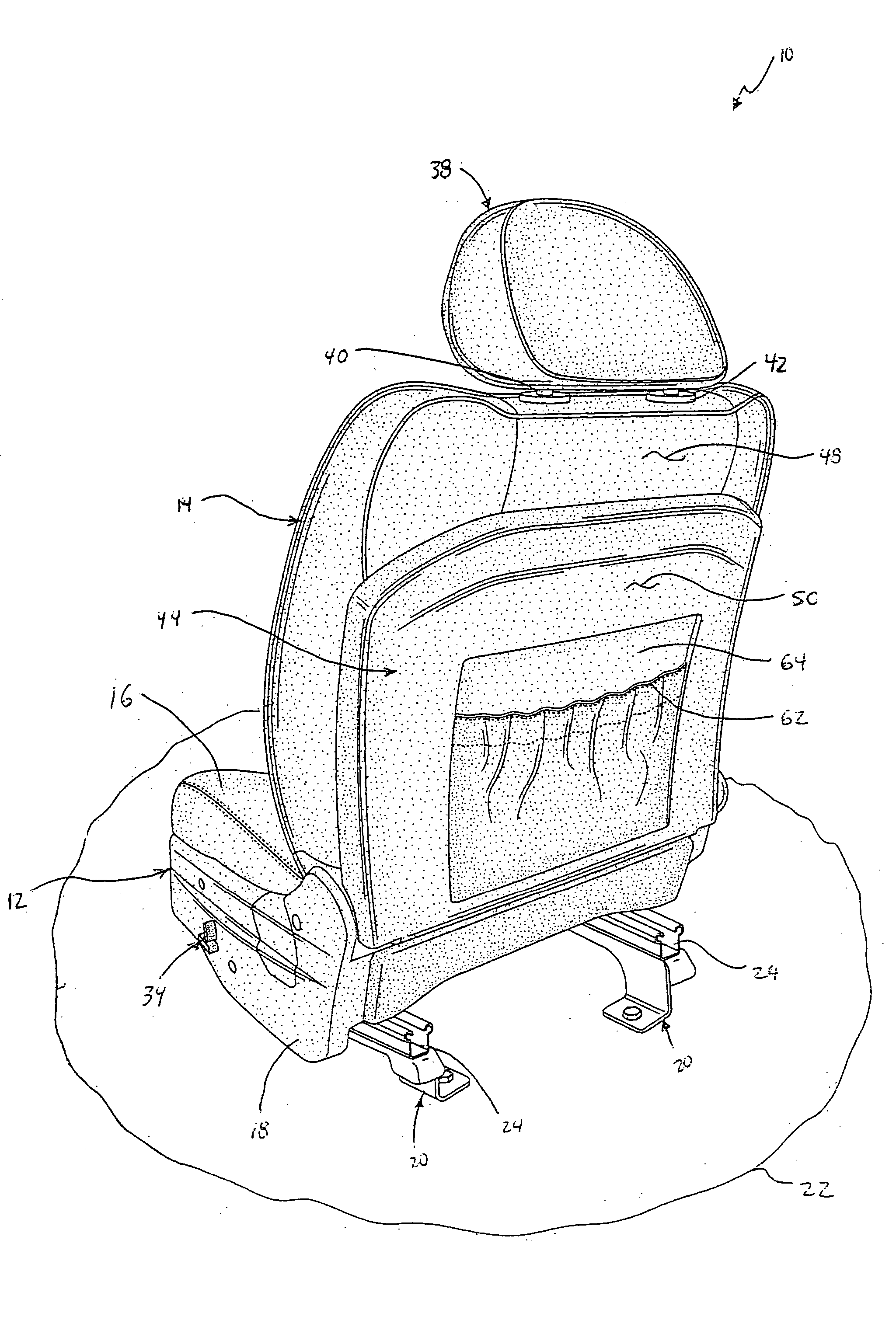

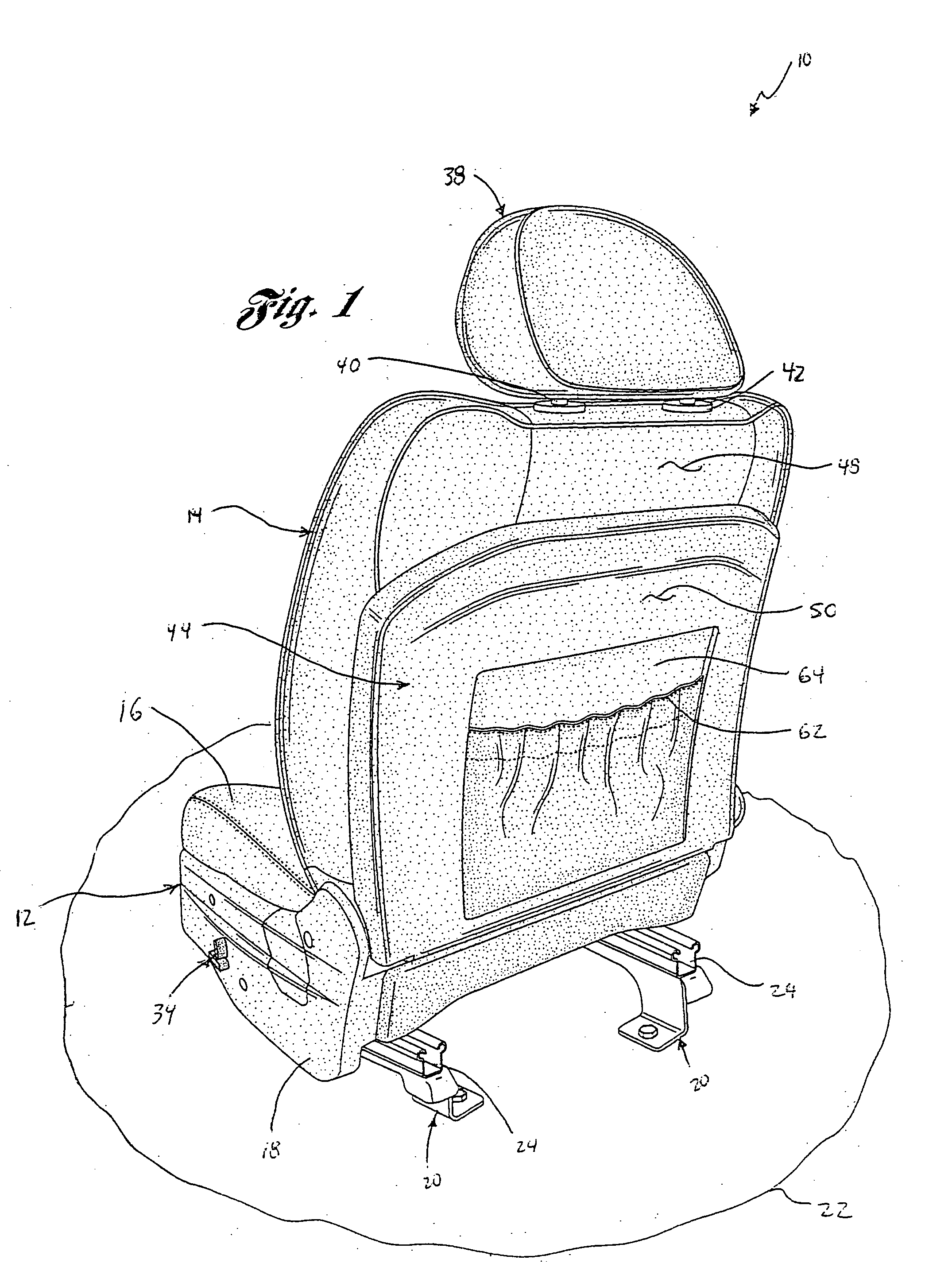

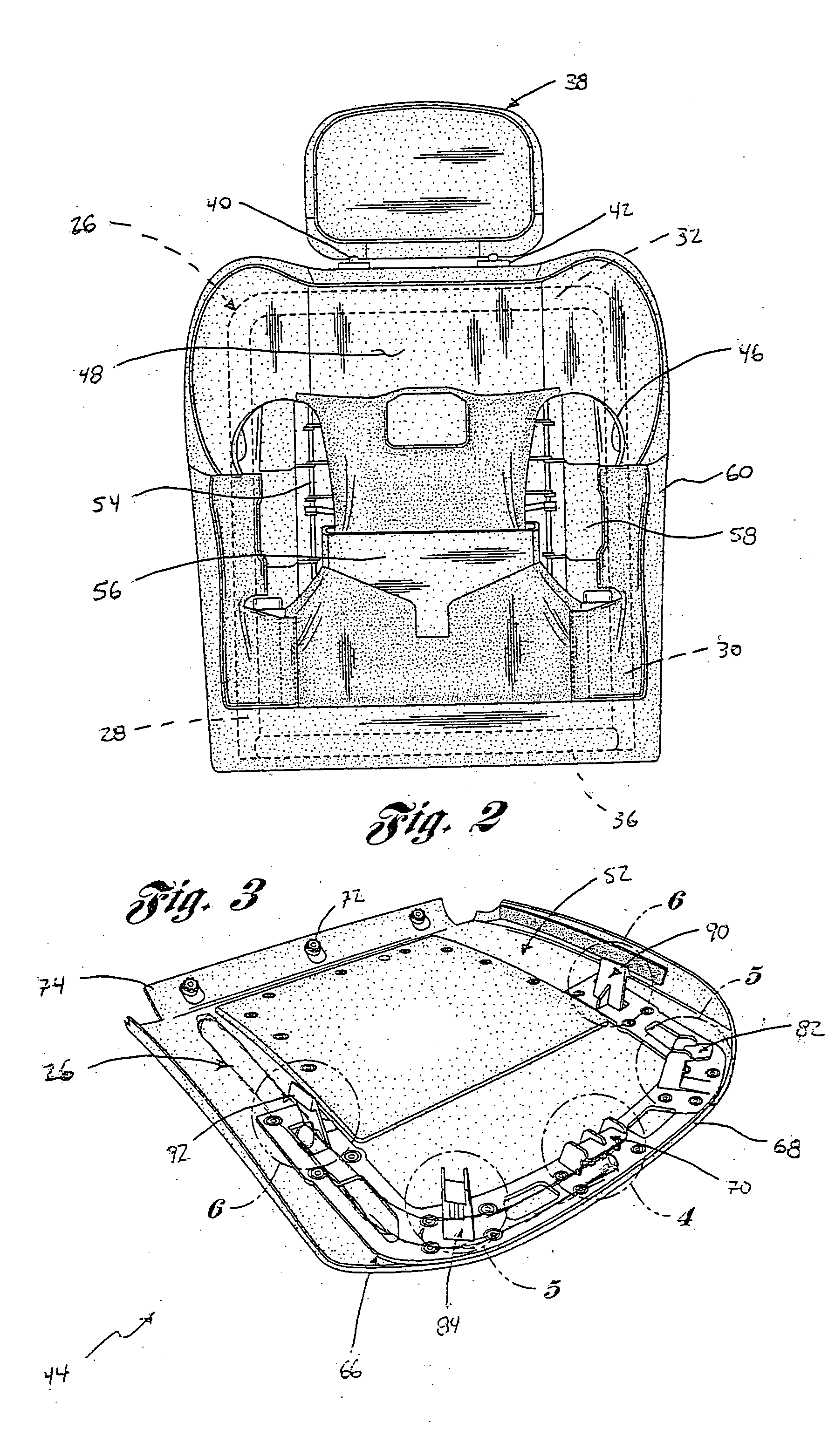

[0015] Referring now to FIG. 1, a vehicle seat assembly 10 is illustrated having a seat bottom 12 and a pivotally connected seat back 14. Seat bottom 12 is conventional in design and can be constructed in accordance with any known manner. Seat bottom 12 generally includes a structural frame (not shown) covered by an outer finish cover material 16 extending about a foam pad layer or other suitable seating material. It is contemplated that cover material 16 may include fabric, vinyl, leather or other materials used in the vehicle passenger compartments based on manufacturing requirements. The upper portion of seat bottom 12 is designed to support the lower body portions of an occupant of the vehicle.

[0016] Seat bottom 12 includes a base 18 adjustably mounted to a support assembly 20. As shown in FIG. 1, support assembly comprises a pair of rails 20 mounted to the floor 22 of the vehicle. Each rail 20 includes a channel 24 extending longitudinally through the rail which receives a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com