Battery system thermal management

hermal management technology, applied in the field of thermal management, can solve the problems of prior art generally failing to provide a power supply system thermal management and operation, and achieve the effect of improving the power supply system and the method of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

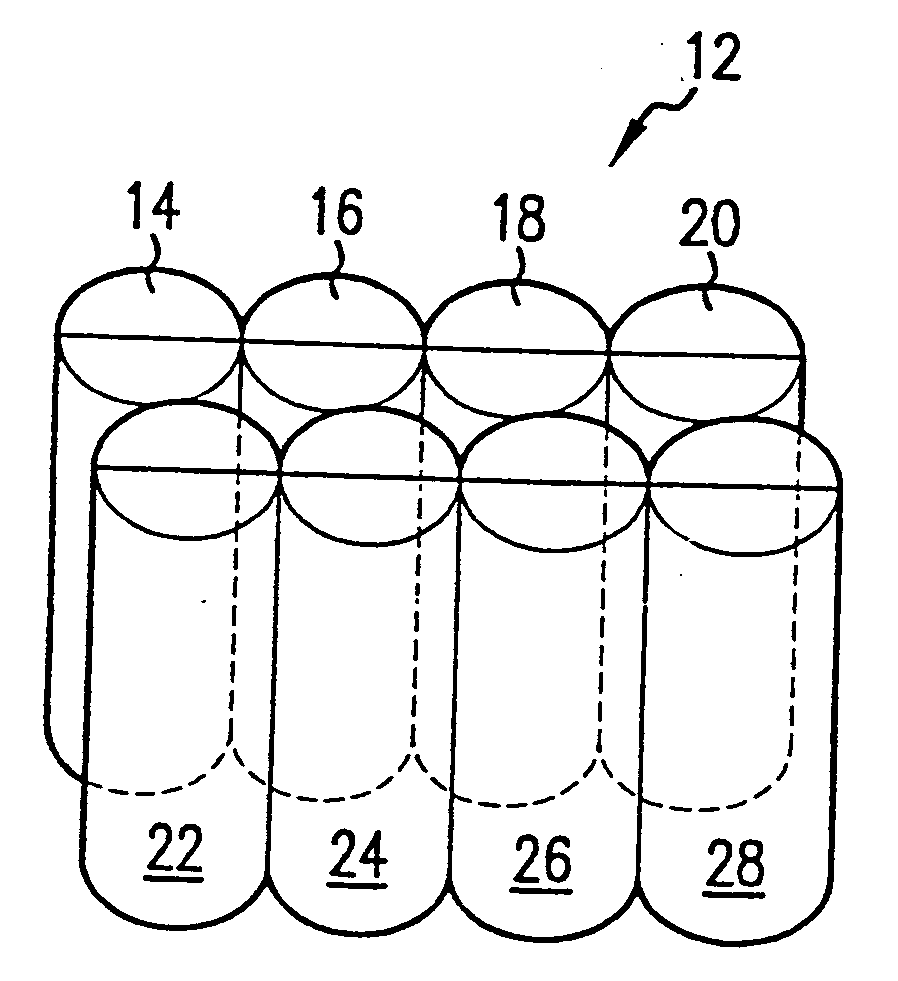

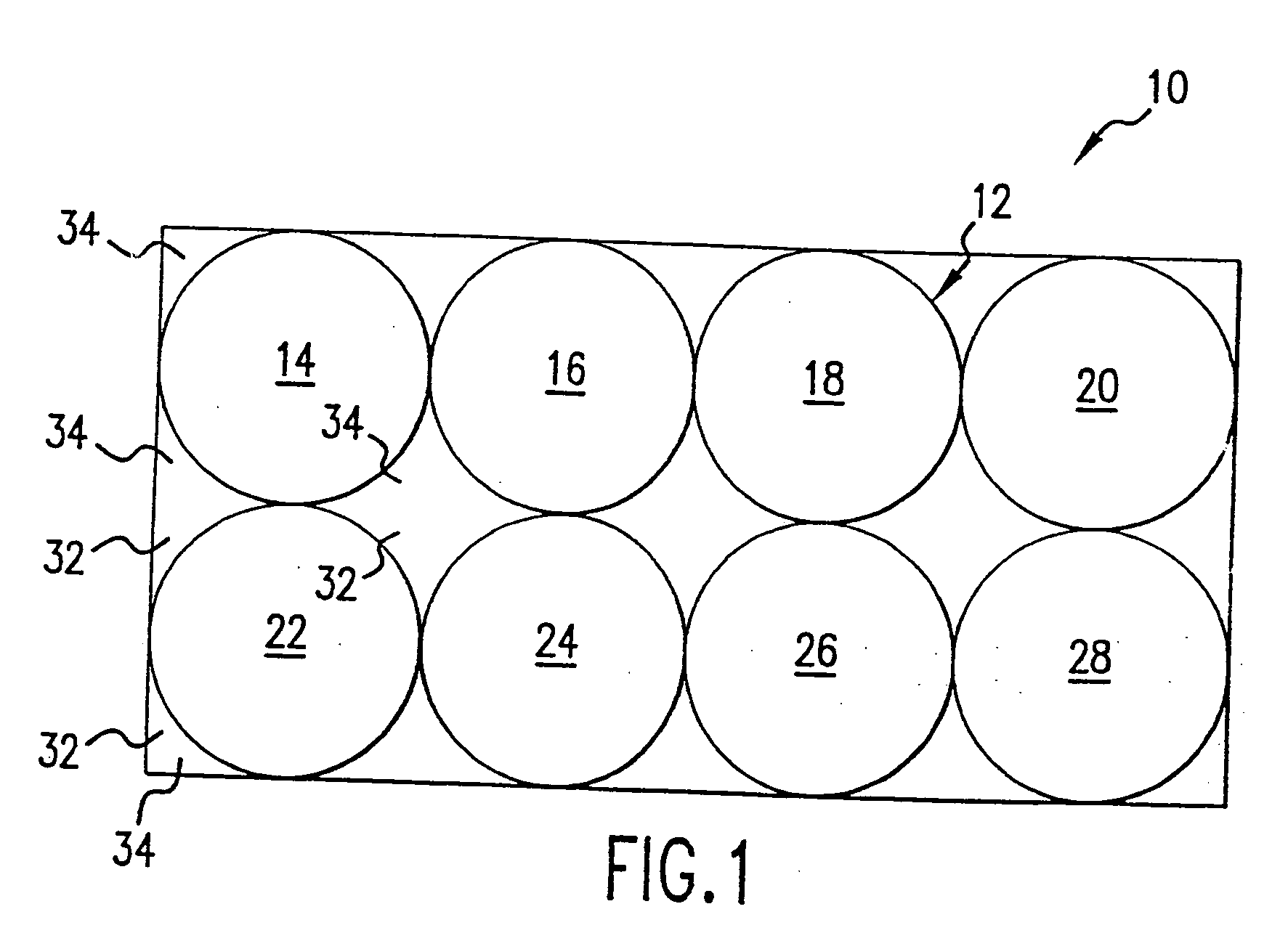

[0076] For purposes of these simulation examples, battery module quadrants corresponding to those shown and described above relative to FIGS. 11, 12 and 13 were evaluated at four selected cooling rates, e.g., h=0, 10, 50 and 100 W·m−1·K−1, respectively, with temperature measurements at the locations designated “1”, “2”, “3”, “4” and “5”, as shown on FIGS. 11, 12 and 13, respectively. As shown, the point or location designated “1” is a cell present on the inner side or region of the module. The point or location designated “2” is a cell present on the outer side or region of the module. The point or location designated “4” correspond to the center or central region of the respective module quadrant.

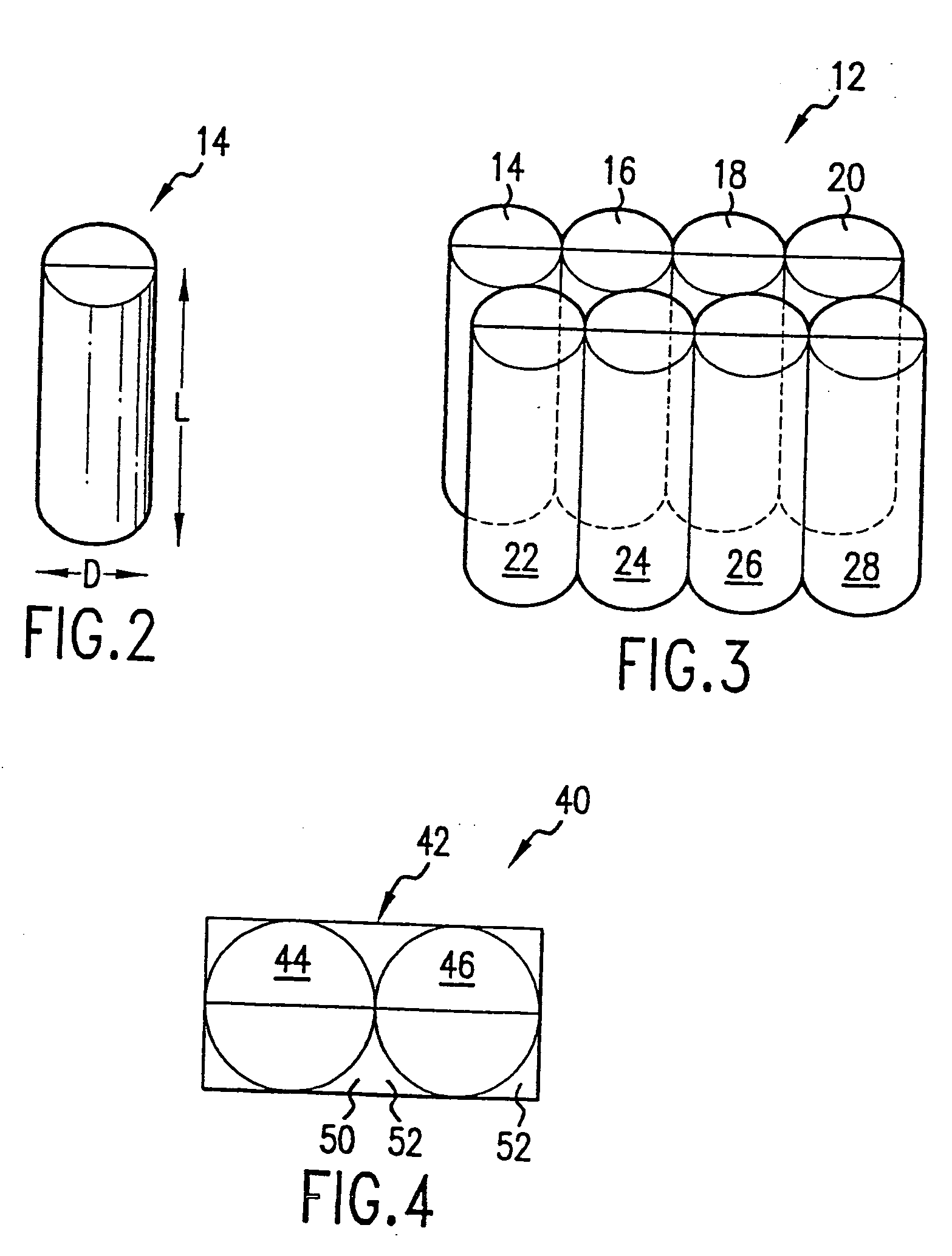

[0077] In each case: [0078] a. each of the four electrochemical cells were Li-ion cells each having a capacity of 1.8 Ah with a diameter (corresponding to D shown in FIG. 2) of 18 mm and a height or length (corresponding to L shown in FIG. 2) of 65 mm. The four cells in each of the module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com