Shelf assembly for a refrigerator compartment

a refrigerator and shelf technology, applied in the field of refrigerator shelf assembly, can solve the problems of more expensive shelves, such as encapsulated shelves, and prove competitively disadvantageous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

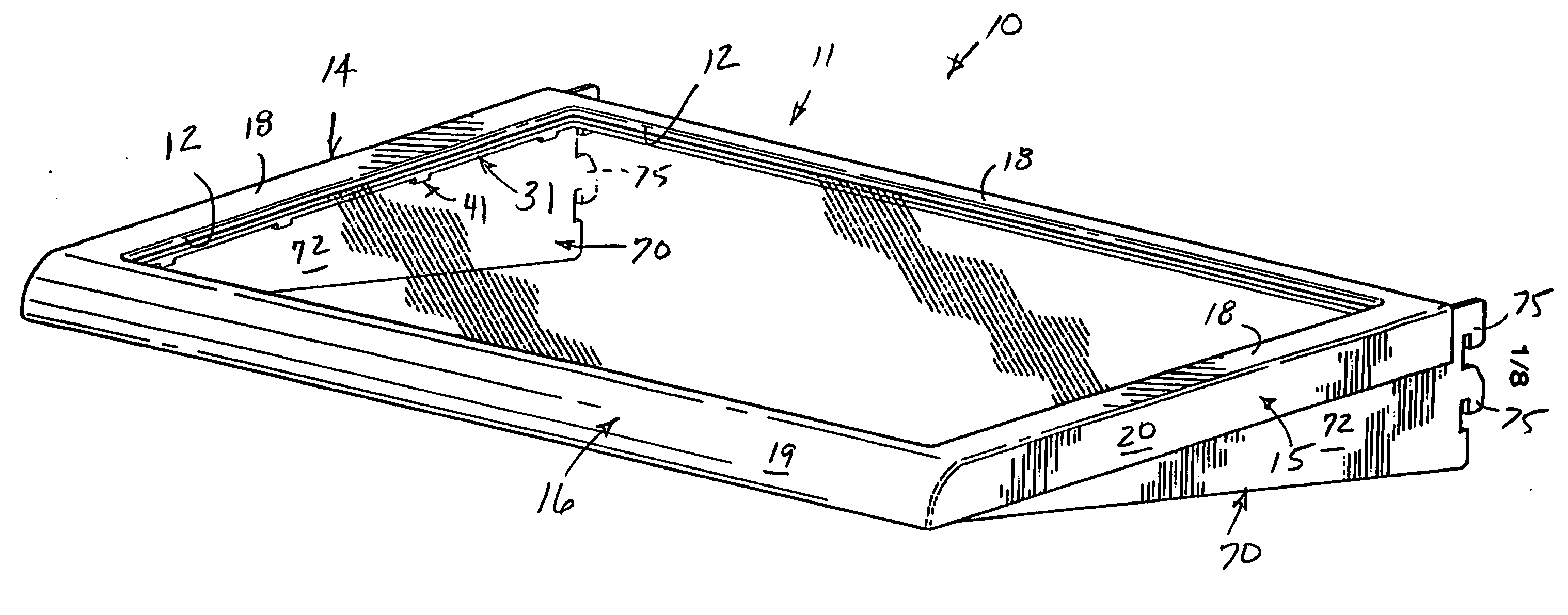

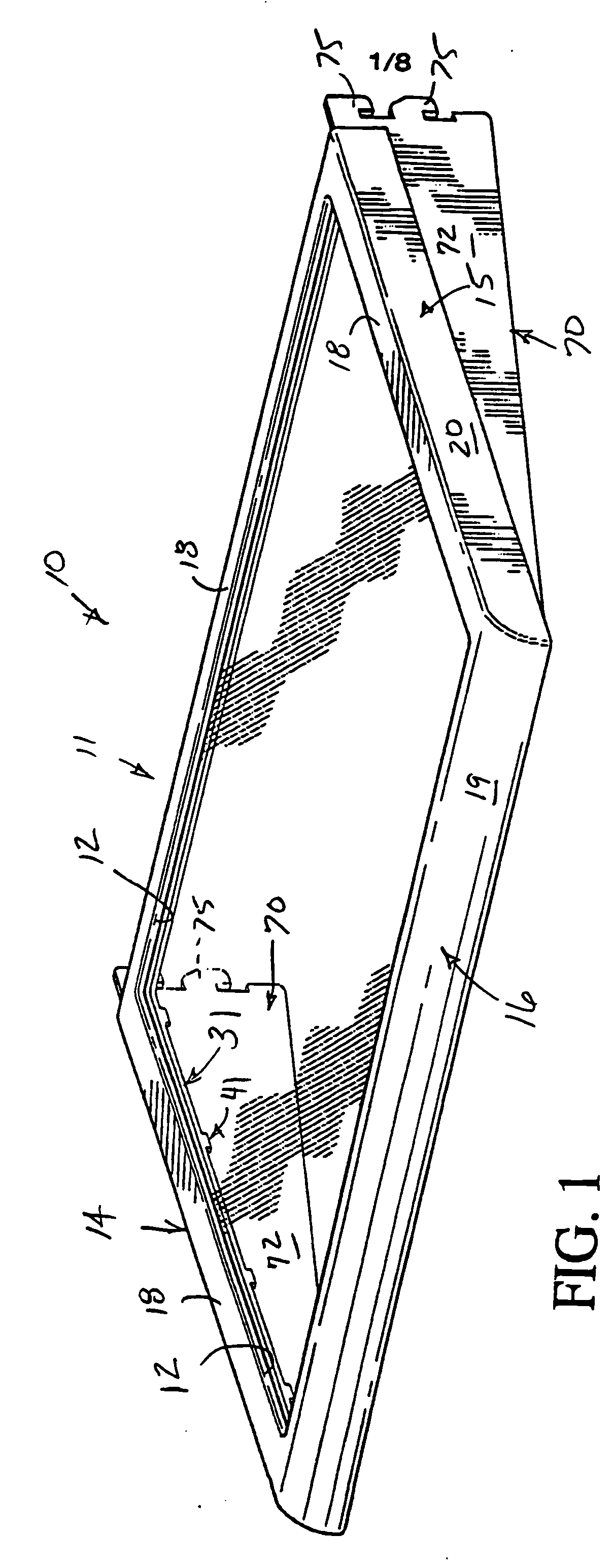

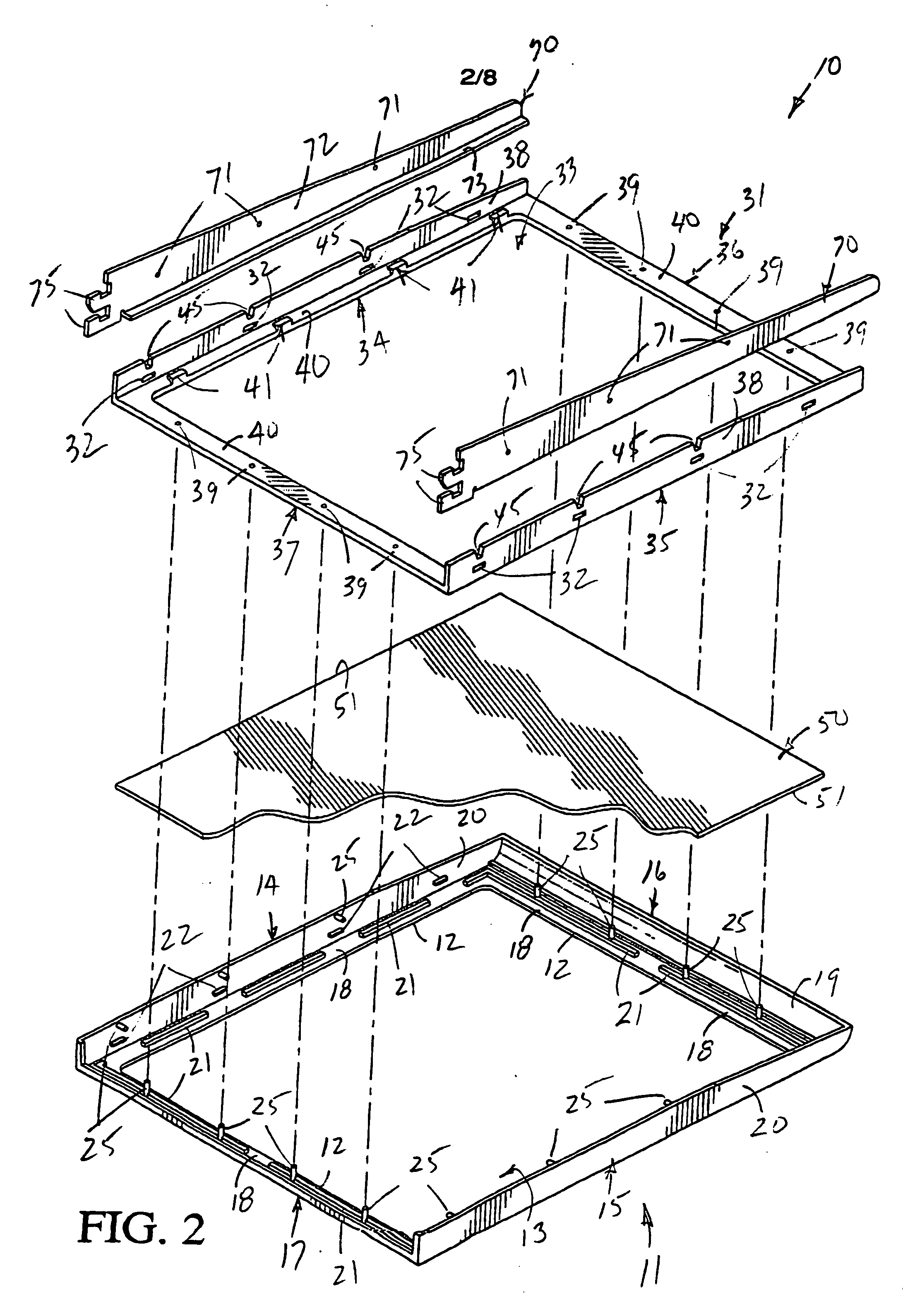

[0028] A novel shelf or shelf assembly constructed in accordance with this invention is illustrated in FIGS. 1 through 8 of the drawings and is generally designated by the reference numeral 10. The shelf or shelf assembly 10 is designed for vertical step-adjustment with respect to a conventional pair of substantially vertically disposed slotted tracks T1, T2 (FIG. 12) in a freezer and / or fresh food compartment C of a conventional refrigerator R which also includes opposite horizontally aligned and vertically spaced pairs of ledges L1, L2 in respective side walls S1, S2 of the compartment C for slidably accommodating another shelf 10′ of the invention which will be fully described hereinaftrer.

[0029] The shelf assembly 10 of FIGS. 1 through 8 and 12 is defined by a pair of substantially polygonal open polymeric / copolymeric synthetic plastic material frame members, including an upper, uppermost, outer or outermost open frame member 11 and an inner, innermost, lower or lowermost subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com