Method and apparatus for forming structural members

a structural member and contouring technology, applied in the field of structural member manufacture, can solve the problems of wrinkling of the plies, time-consuming manual layup process,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention now will be described more fully with reference to the accompanying drawings, in which some, but not all embodiments of the invention are shown. This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth. Like numbers refer to like elements throughout.

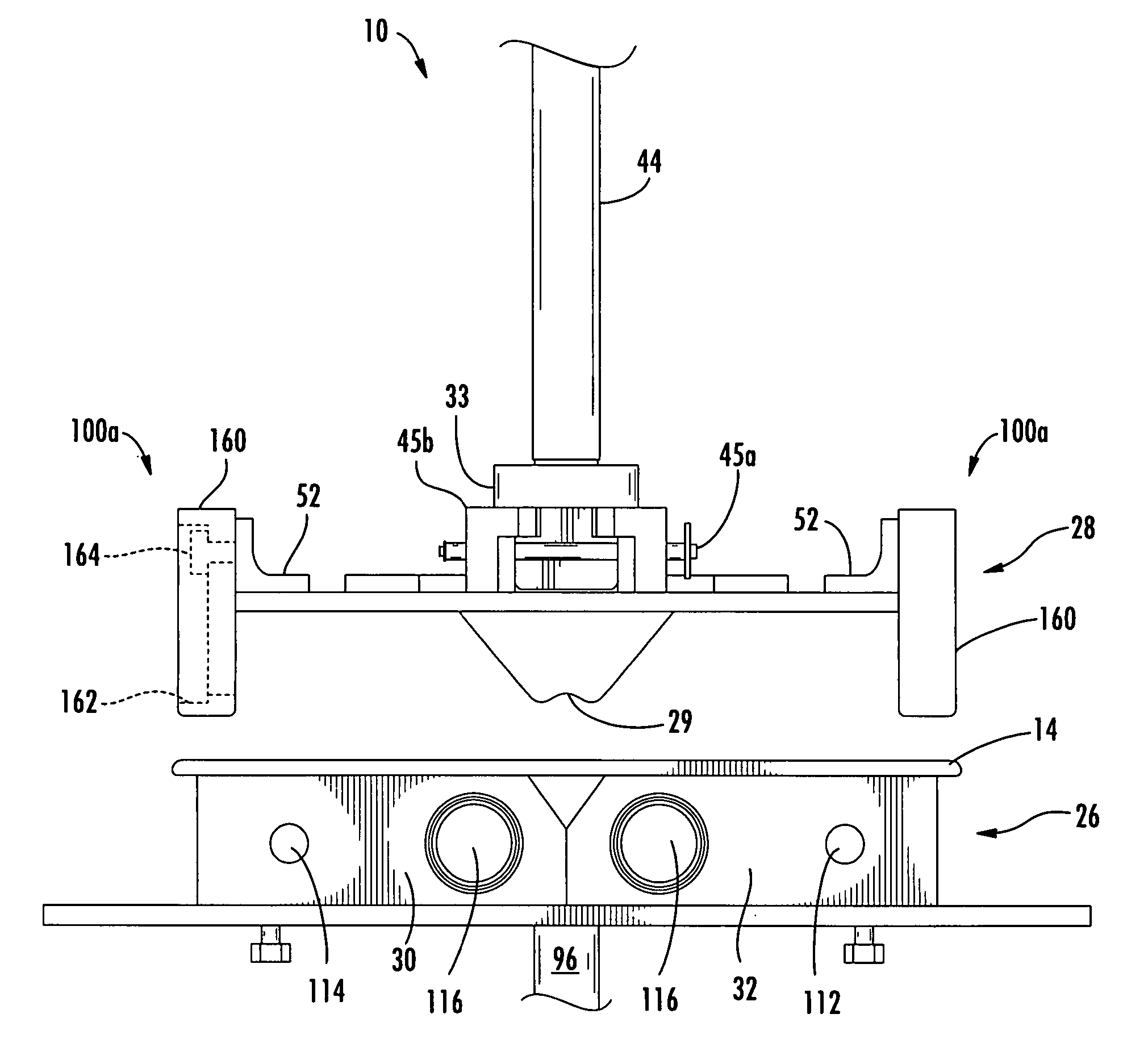

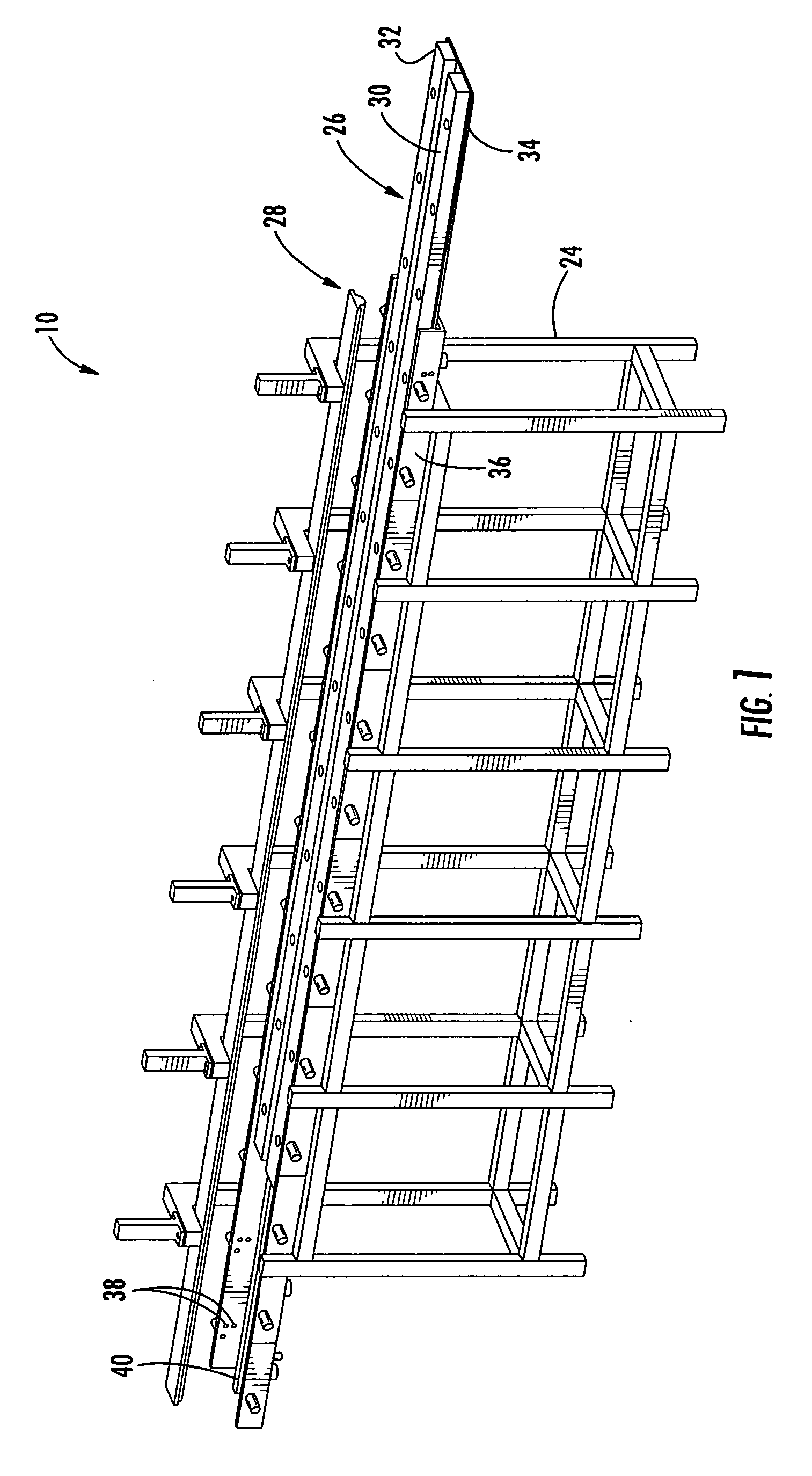

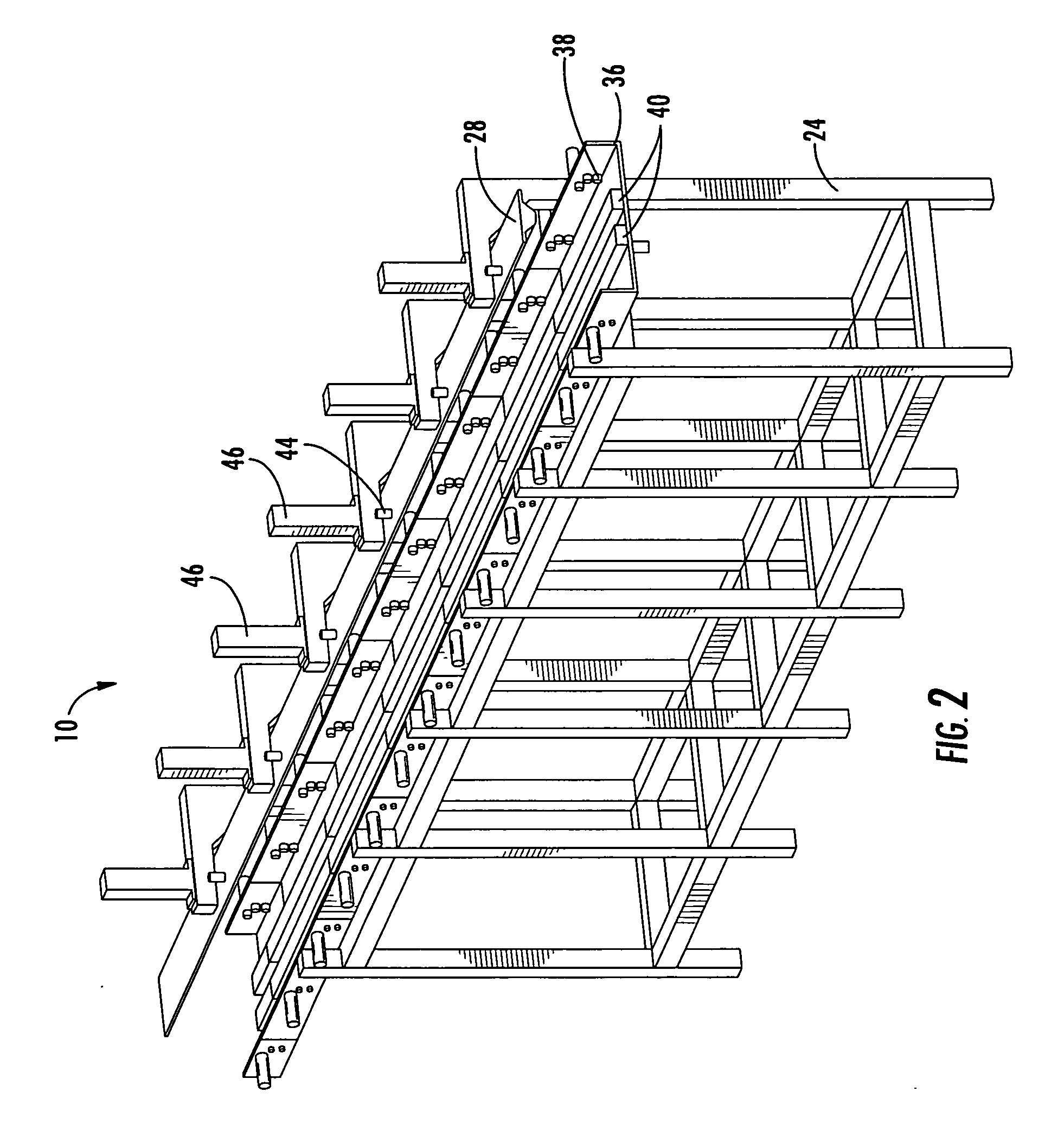

[0039] Referring now to the drawings, and in particular to FIGS. 1, 5, and 12, the apparatus 10 for forming structural members 12 according to one embodiment of the present invention can be used for forming structural members 12 of various sizes and configurations. The configuration shown in FIG. 12 and described throughout this description is a hat stringer for making a hat section stiffened composite. While shown as generally straight, the stringer may be curved or have complex curvature, as appropriate for the intended application. The structural members 12 are typically manufactured from a blank or charge 14. In particular, the charge 14 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Electric charge | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com