Washing machine including a shipping protection arrangement

a protection arrangement and washing machine technology, applied in other washing machines, cleaning using liquids, textiles and paper, etc., can solve the problems of container wall deformation, container wall destruction or deformation, and rod solutions known in the prior art are not suitable for suds containers made of plastic, etc., to prevent the effect of destroying or deforming the container wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

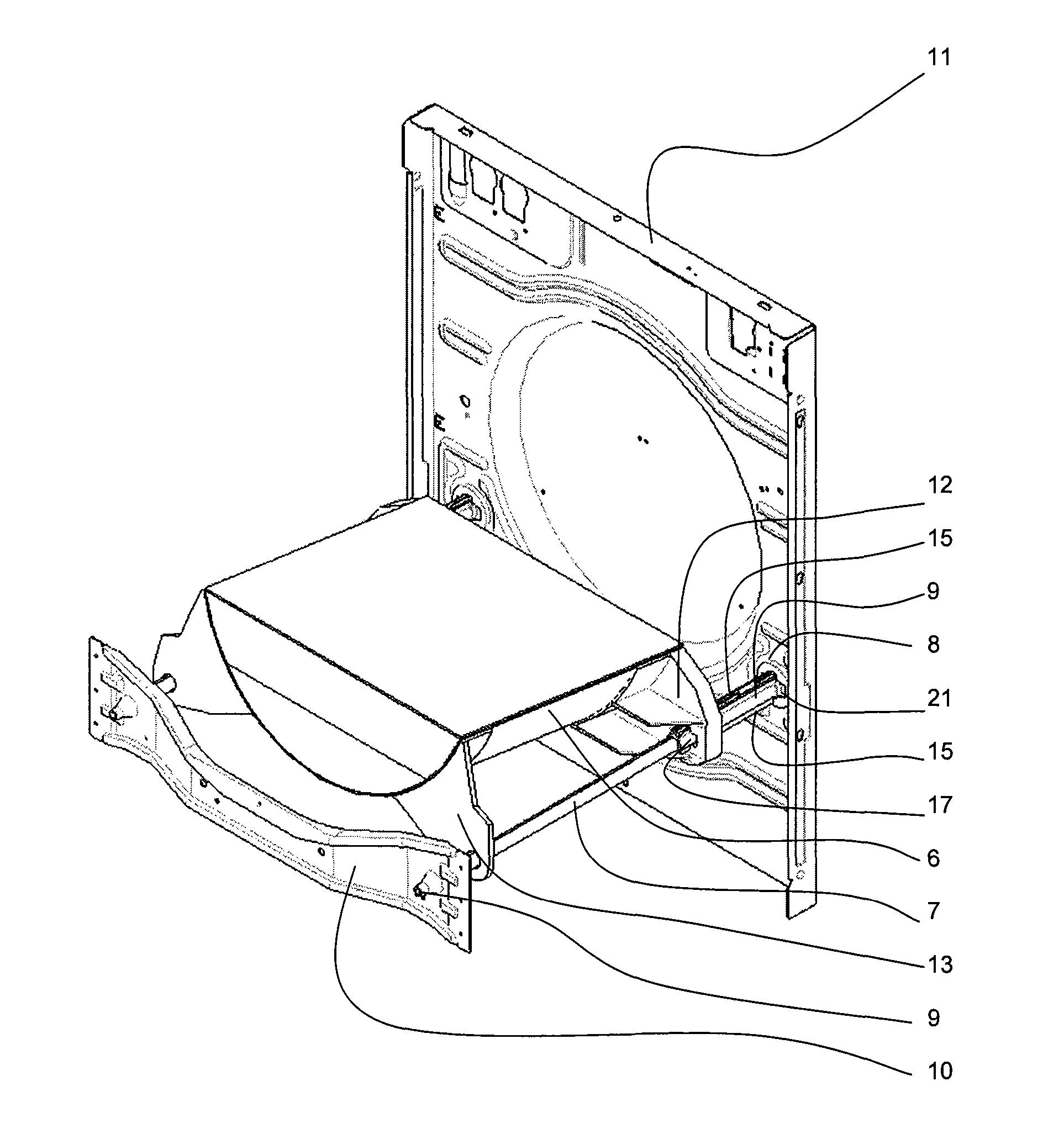

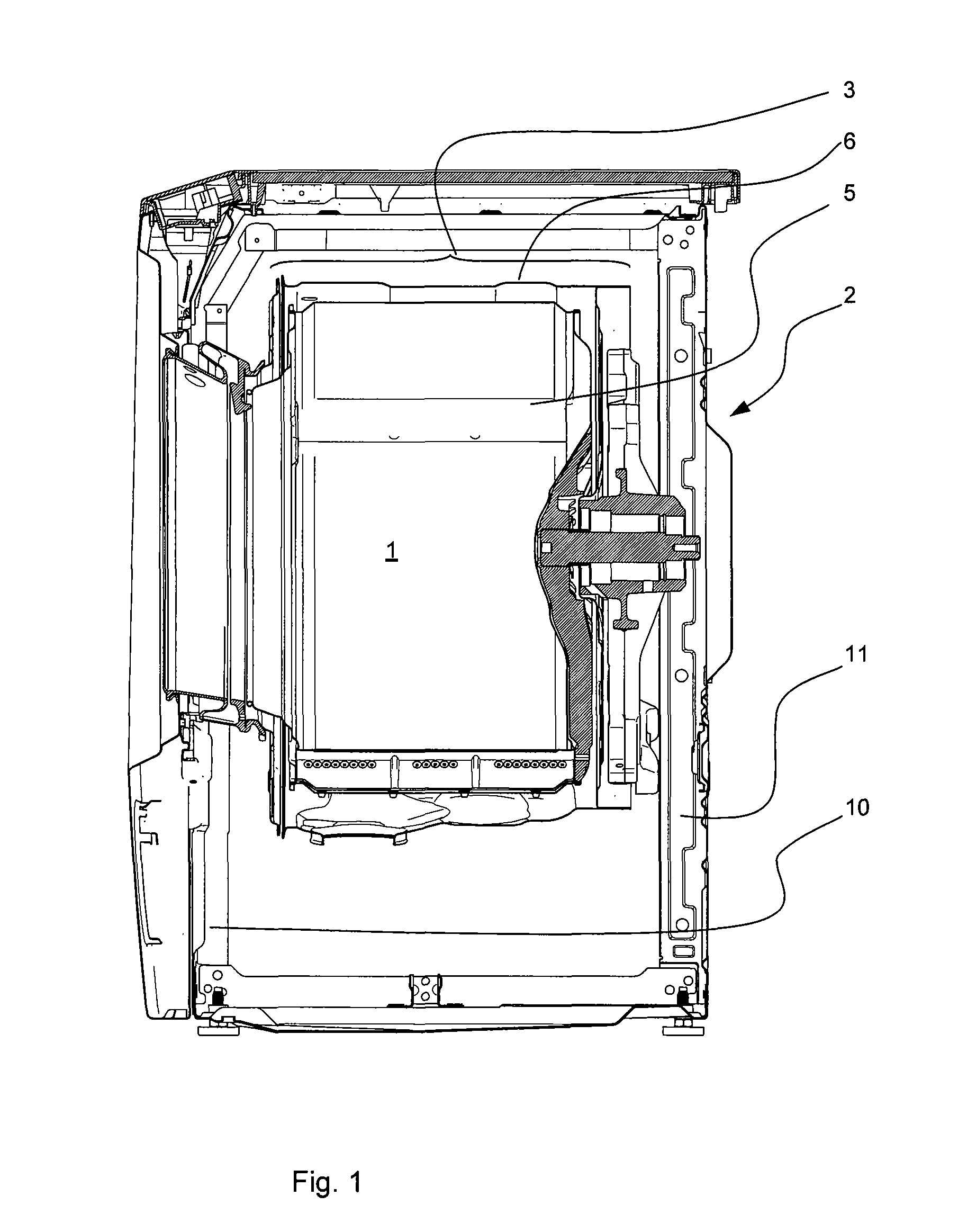

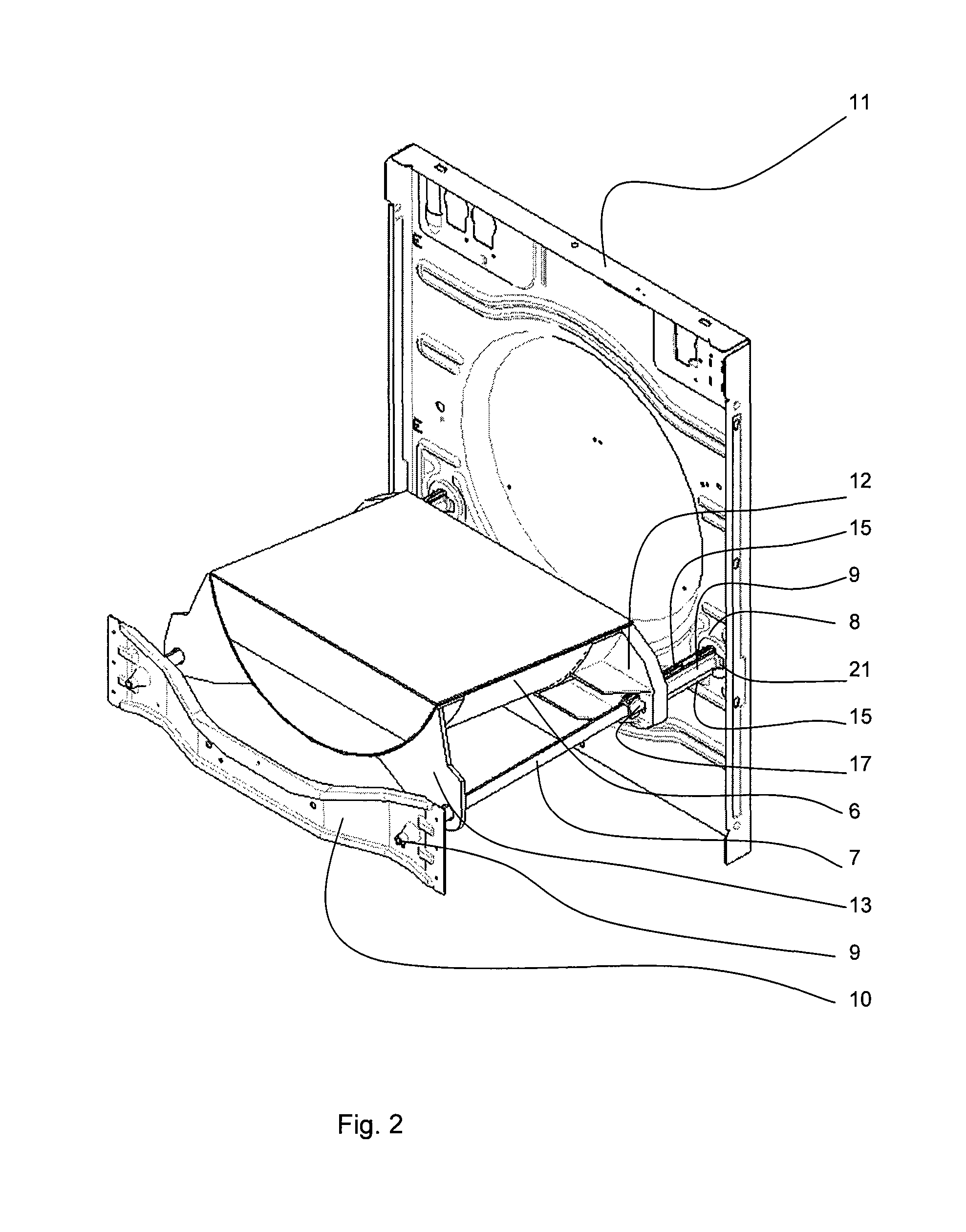

[0023]FIG. 1 is a cross-sectional overview of a washing machine 1. Housing 2 includes a rear wall 11 and a front housing part 10, said housing part 10 being either a frame element extending along the front or a front wall. Assembly 3, which includes a drum 5 and a suds container 6 enclosing drum 5, is resiliently mounted inside housing 2.

[0024]FIG. 2 shows a perspective view of the rear wall area of the appliance housing 2 of a washing machine, in which housing the washing assembly is resiliently mounted. In addition to washing drum 5 shown in FIG. 1, the washing assembly also includes a suds container 6 enclosing washing drum 5, said suds container being sketched here only schematically. Suds container 6 is protected against shocks by shipping protection devices in the form of shipping rods 7. When in the secured position, rods 7 are located in holding receptacles 9 in front housing part 10 and in further holding receptacles 8 in rear wall 11. In the central portion, rods 7 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com