Outsole with anti-slip tread

a technology of anti-slip rubber and outsole, which is applied in the direction of fastenings, uppers, bootlegs, etc., can solve the problems of large loss of contact area and little traction of outsoles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

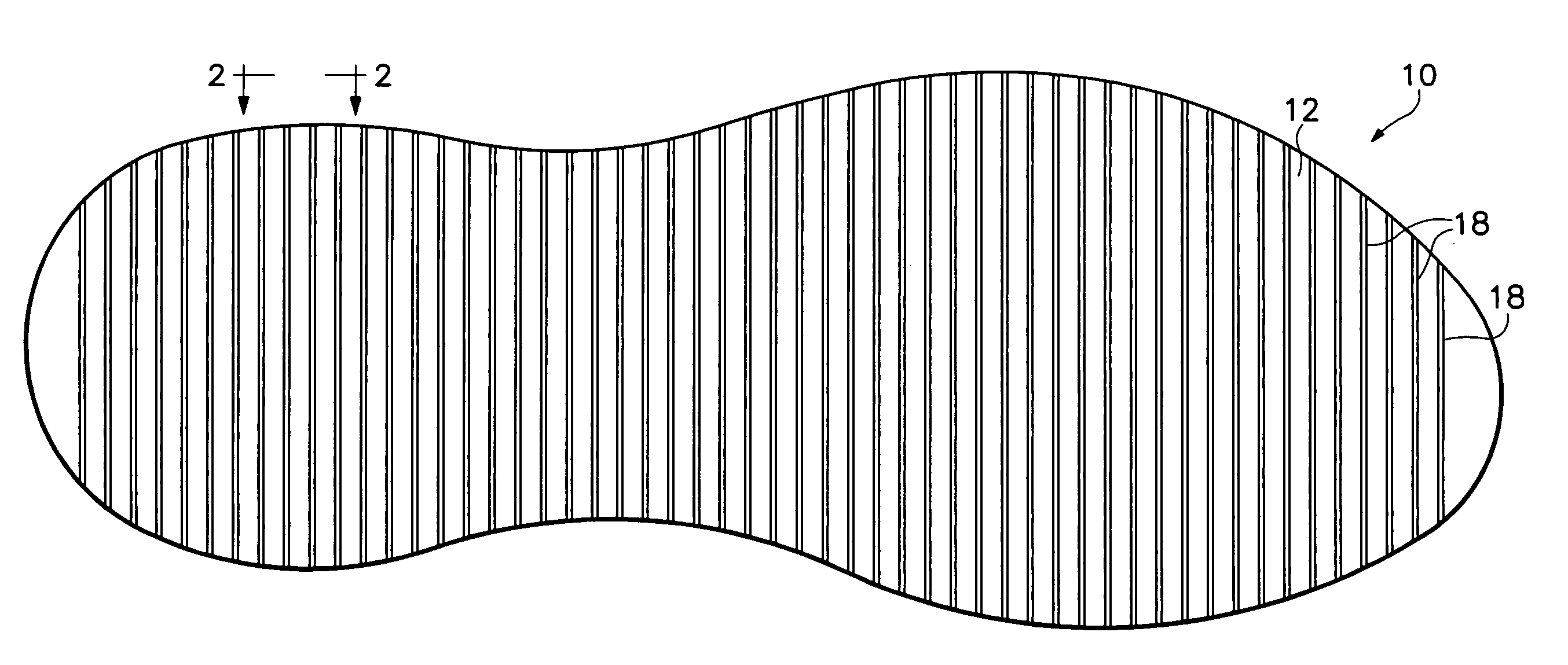

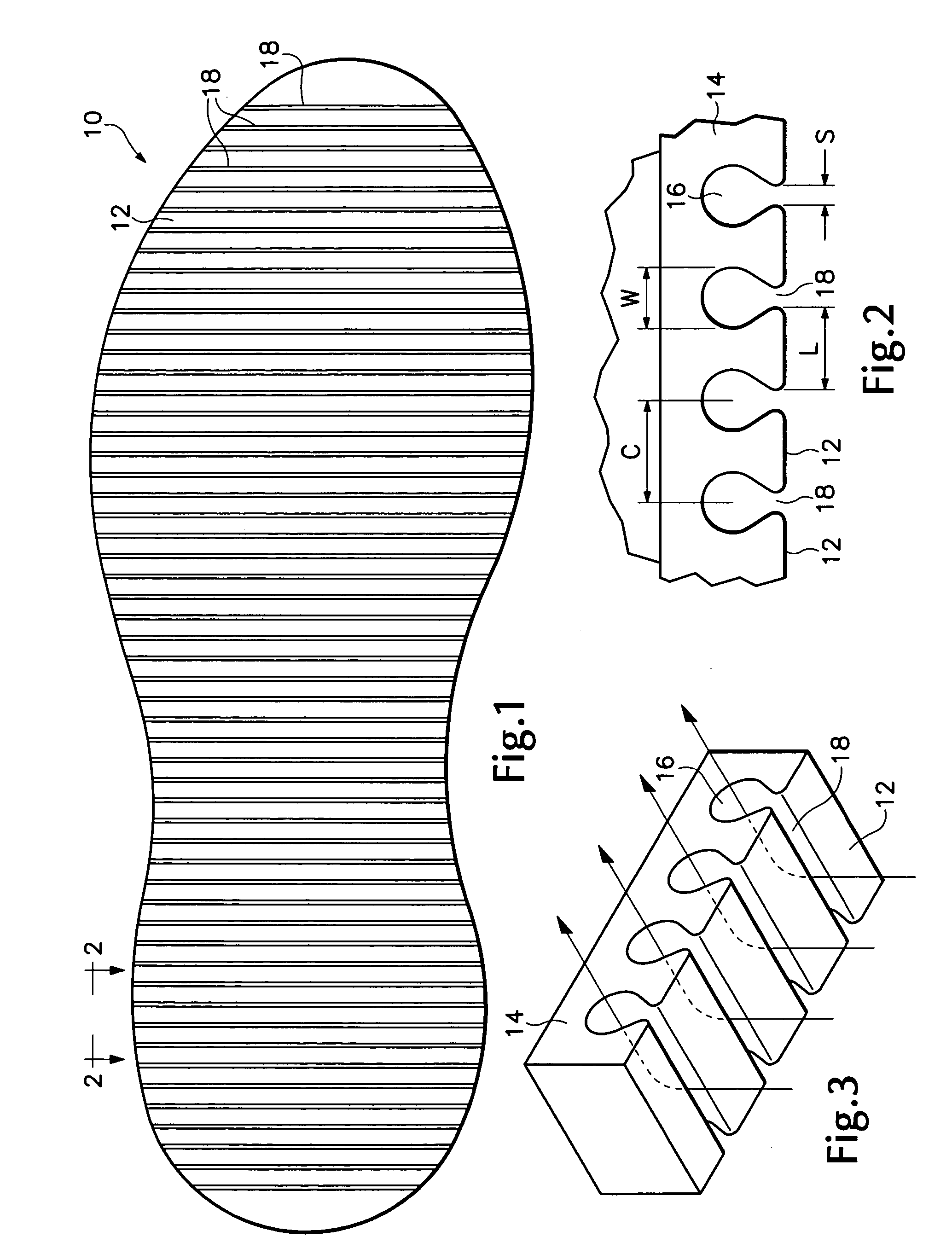

[0007] Referring now to the drawings, a footwear outsole 10 has a generally planer outwardly facing contact surface 12 and a sidewall 14 that extends around the periphery of the contact surface and is substantially normal to the contact surface. Extending through the outsole are a plurality of conduits 16 having opposed ends which open out of the sidewall. In the embodiment illustrated the conduits are egg-shaped in cross-section, but they could have almost any shape. In the embodiment illustrated the conduits are arrayed in parallel, spaced-apart rows and extend completely across the outsole normal to its longitudinal axis. In a preferred embodiment the conduits are equally spaced and are separated from one another by a distance c. They have a maximum width w along the longitudinal axis of the outsole.

[0008] The conduits 16 open out of the contact surface 12 of the outsole 10 through slots 18 which are formed in the contact surface. The slots 18 have a width s which is less than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com