Yard hydrant with drain port air line

a technology of air line and yard hydrant, which is applied in the field of yard hydrant, can solve problems such as inacceptable cross-connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

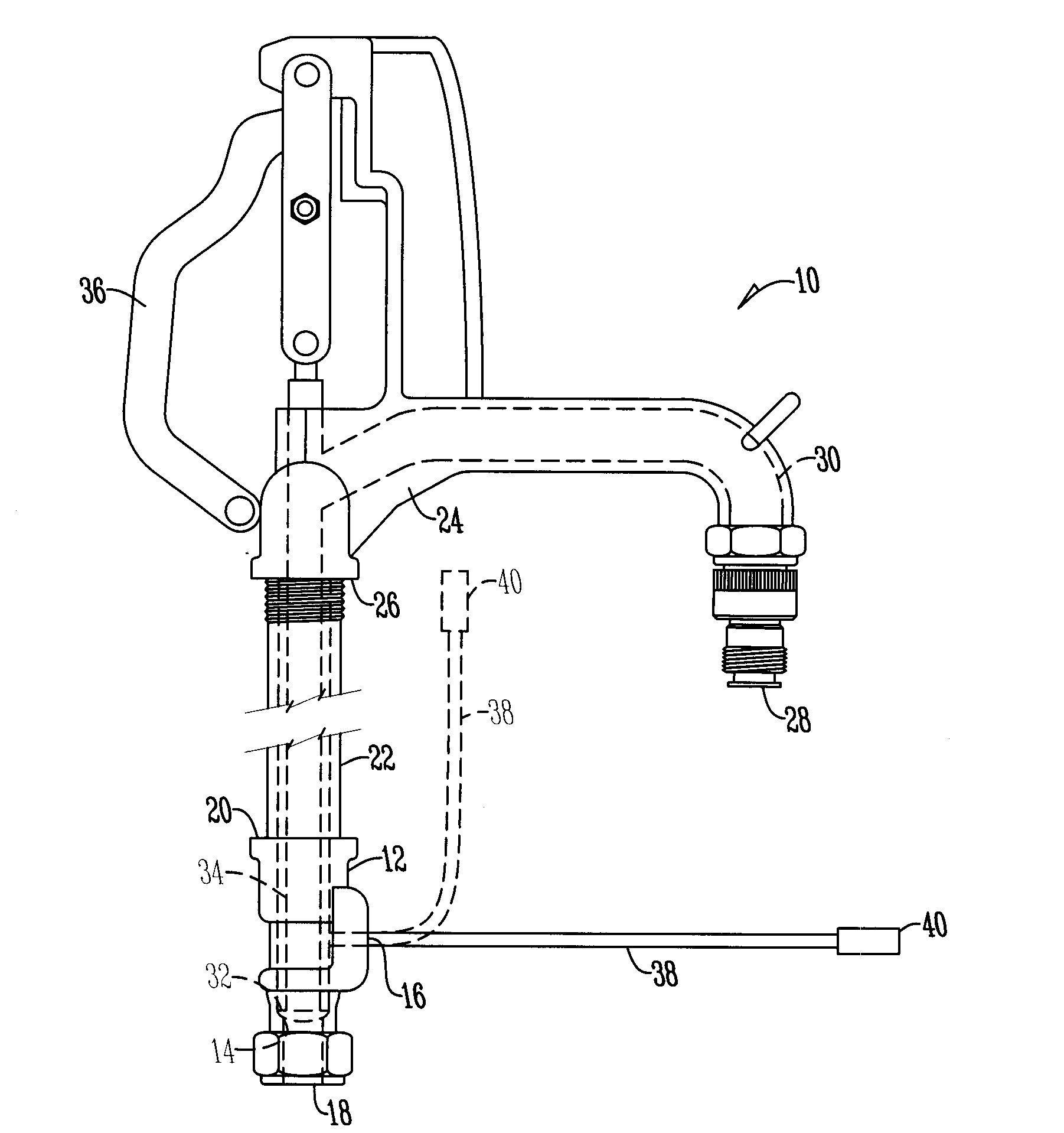

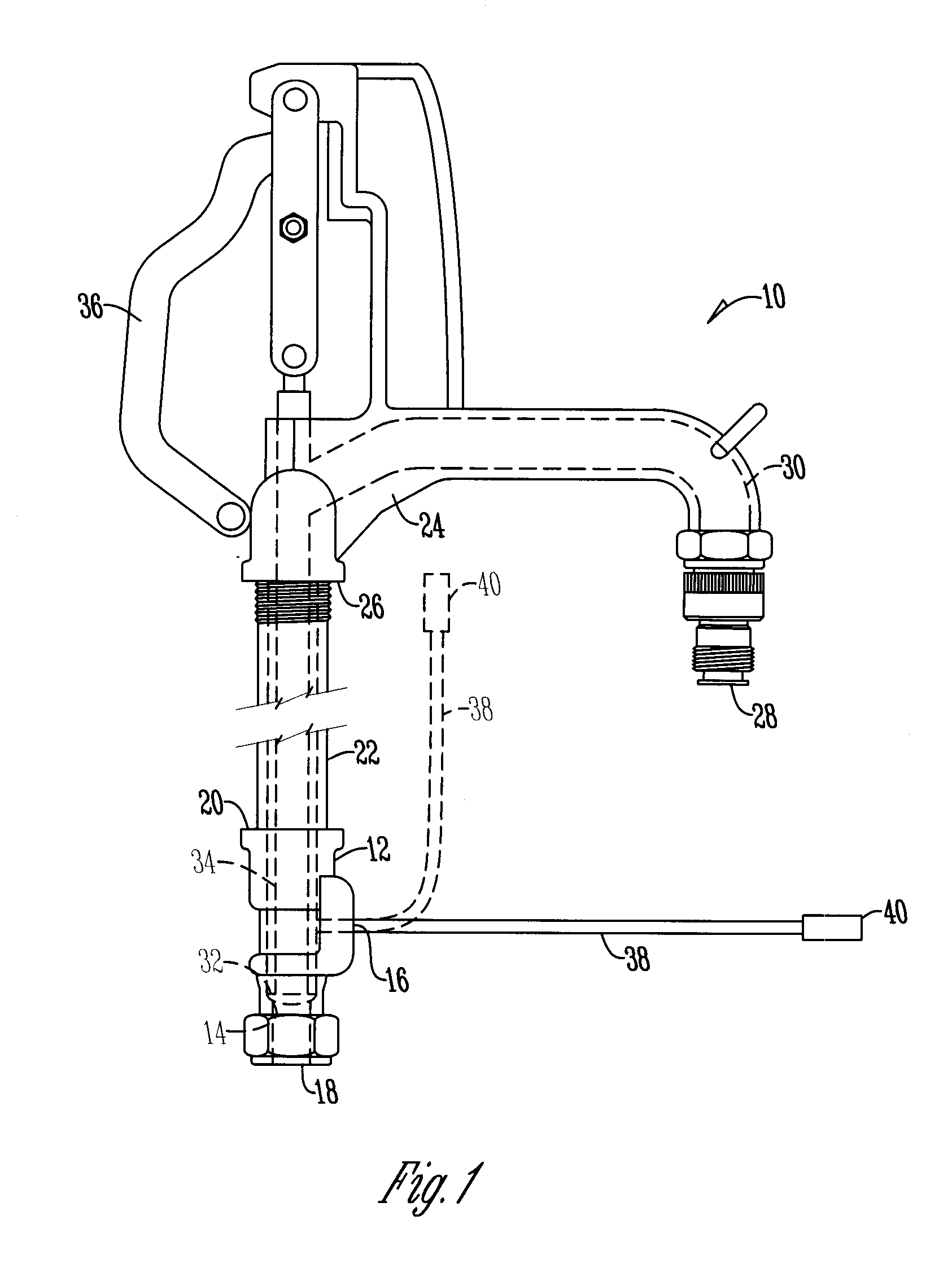

[0008] A yard hydrant 10 has a valve body 12, a valve seat 14, a drain port or hole 16, an inlet 18 which is connected to a source of pressurized water (not shown) and an outlet 20 at its top. Connected at one end to the valve body 12 is a standpipe 22 that extends vertically and is connected to a head casting 24 at the opposite end.

[0009] The head casting 24 has an inlet 26 coupled to the standpipe 22 and a discharge conduit or outlet 28 that preferably extends outwardly from the head casting 24 and a fluid conduit 30 that extends between the inlet 26 and the outlet 28.

[0010] Disposed within the valve body 12 is a closure valve plunger 32 that is connected to a valve stem or actuator rod 34 that extends from the closure valve 32 through the standpipe 22 and is connected to an actuator device 36 attached to the head casting 24 such as a lever or handle.

[0011] Mounted adjacent to the drain port 16 is an air line 38. The air line 38 is mounted to the drain port 16 in any convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com