Frame system with releasable couplers

a frame system and coupler technology, applied in the direction of rod connections, fastening means, constructions, etc., can solve the problems of inability to carry loads, inability to use thin-wall materials, and inability to meet the requirements of construction, etc., to achieve quick and easy jointing of the frame components to each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

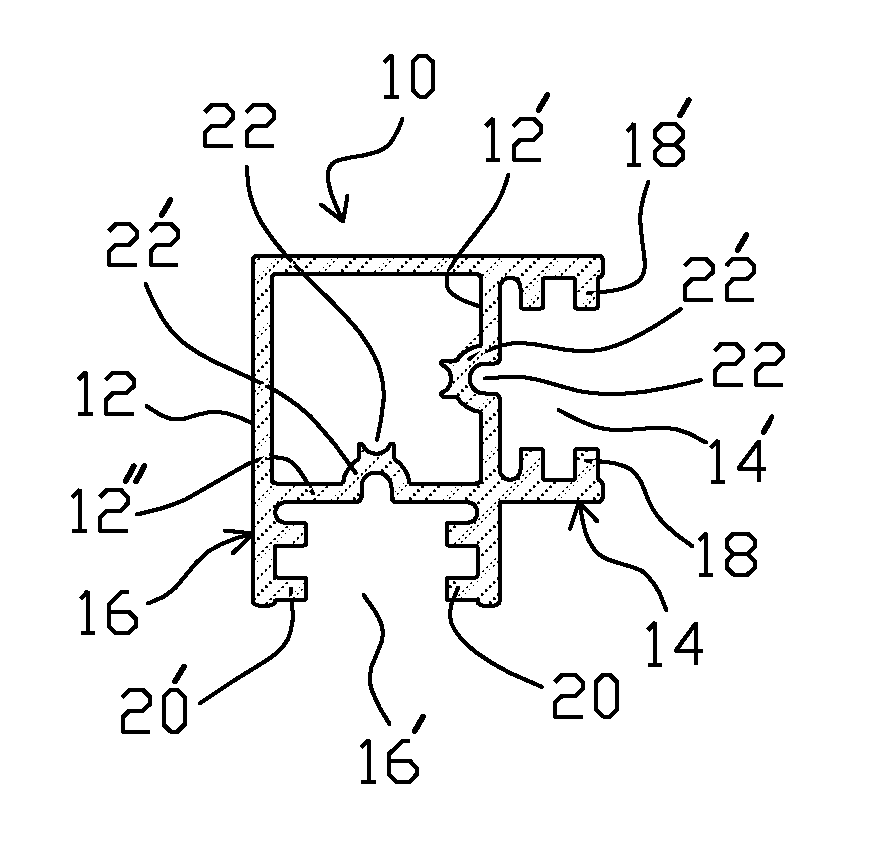

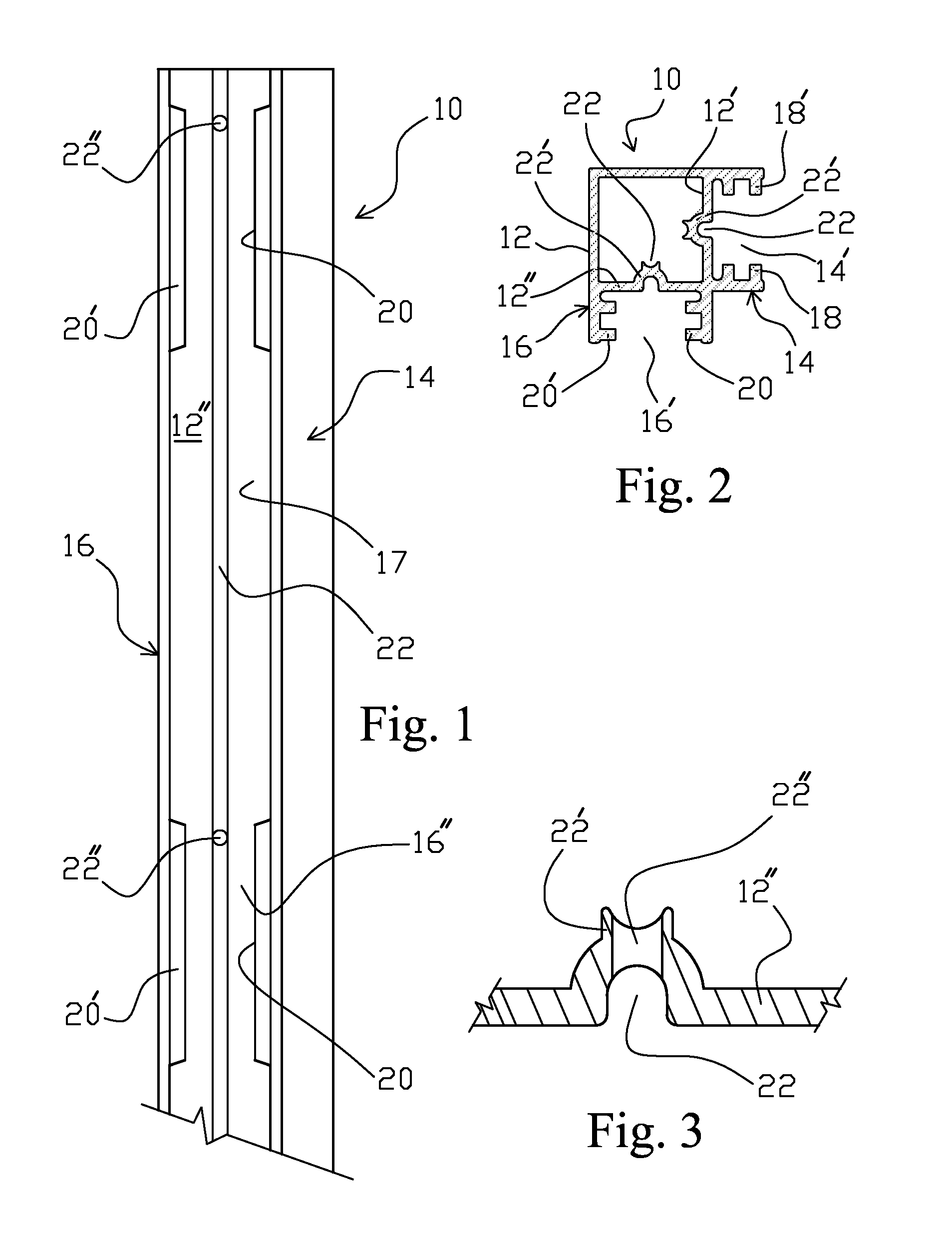

first embodiment

[0068] The sleeve 126 is loosely mounted within one of the elongated web sections 114, 116 by means of cams or wedge-elements 122 located in the interior portion of the web section in close juxtaposition to the associated surface-face or wall of the elongated main section 112 from which the respective web section 114 or 116 projects, as seen in FIGS. 25A-27. The lateral distance between the two cams 122 is such as to loosely retain the sleeve member 126 and cause compression of the sleeve member 126 as it is slid in the web section 114 or 116 and reaches the cam members 122. It is noted that sleeve member 126 is inserted into a web section 114 or 116 at one of the free ends of the web section, and then slid toward the pair of cam members. The free edge-surfaces 128 may be squeezed toward each other by the camming members 122. In any case, the free edge-surfaces 128 are to provide the equivalent of the narrower-gap section 16″ of FIG. 1, whereby these free ends are clearly visible, a...

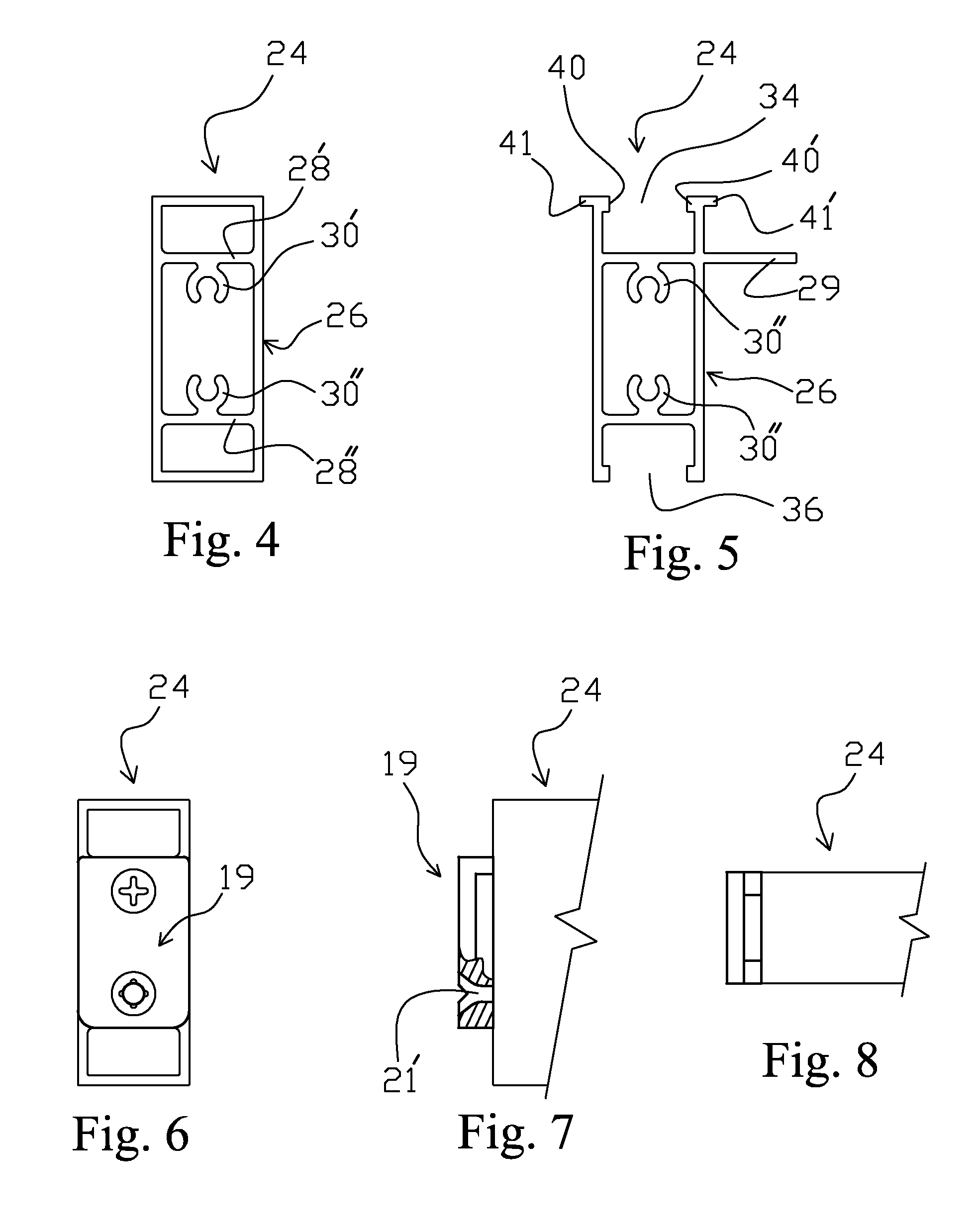

second embodiment

[0072] In a modification the coupler component 118 of the second embodiment shown in FIG. 31A, a double connector 118′ is provided by which the ends of two rail components may be coupled together, in the manner shown in FIG. 39. The double connector 118′ consists of two regular coupler components 118 arranged back-to-back such that the narrower sections 164 face toward each other and are separated by a central spacer element 170, defining an upper and a lower cutout or recess 170′, 170″ in each of which is flush-mounted a bent end 172 of one of the wider sections 168. This double connector 118′ is used for connecting together two post components parallel to each other, as shown on FIG. 39, with the parallel-arranged, or back-to-back, post components being oriented 180m degrees opposite to each when mounted in such a back-to-back connection. For those rail components that are also provided with web-sections similar to web-sections 14 and 16 of the post component 10, the double connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com