Button actuated spill-proof lid for travel mug

a technology for travel mugs and lids, which is applied in the field of beverage containers, can solve the problems of difficult one-handed operation of mugs, latch mechanisms, and latches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

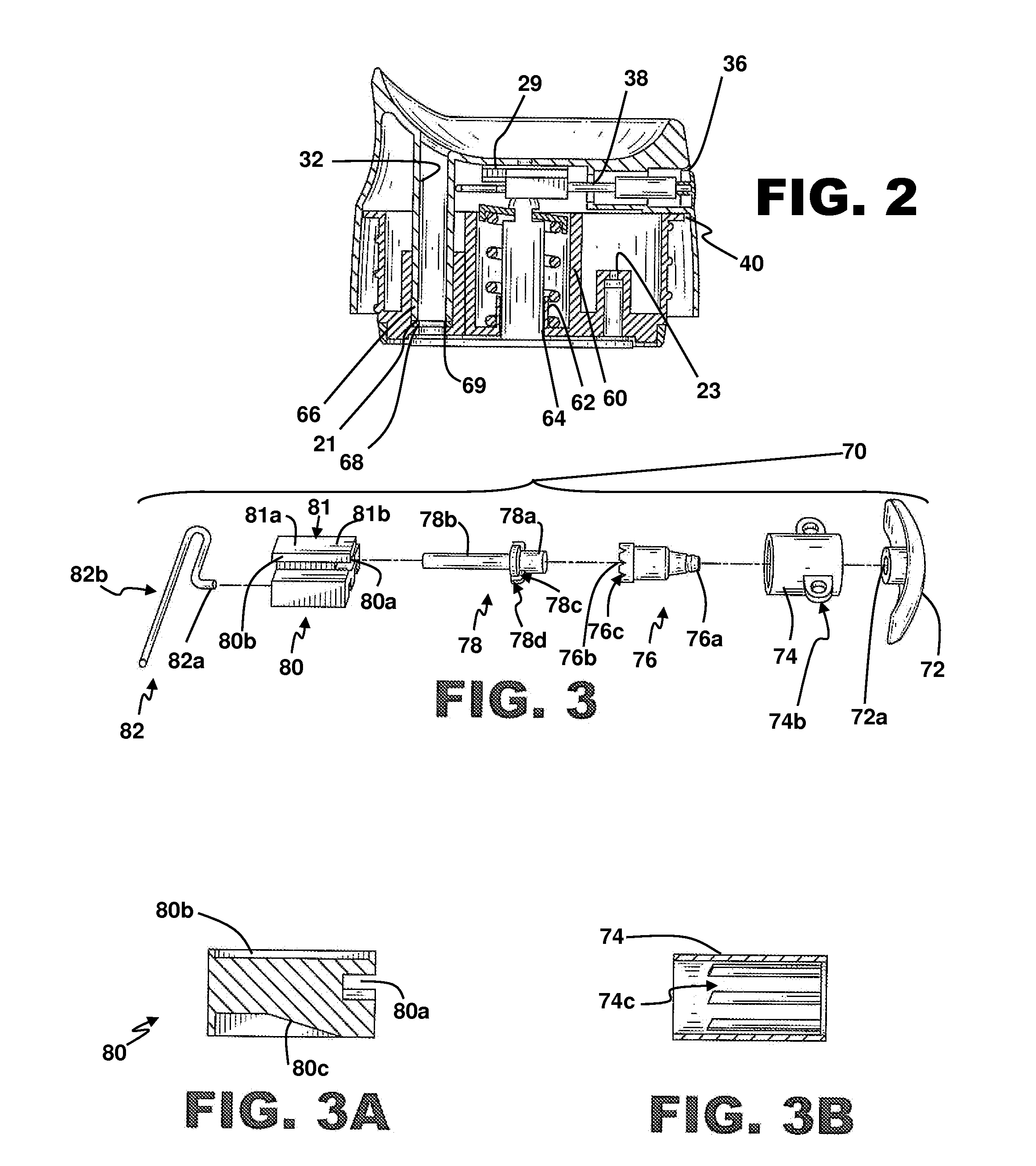

[0021]An exemplary embodiment of a mug lid assembly, hereinafter referred to as a mug lid, generally identified by reference numeral 10, is illustrated in the Figures. The mug lid 10 may comprise a top shell 20, a bottom member 50, an actuator assembly 70, and a valve assembly 100.

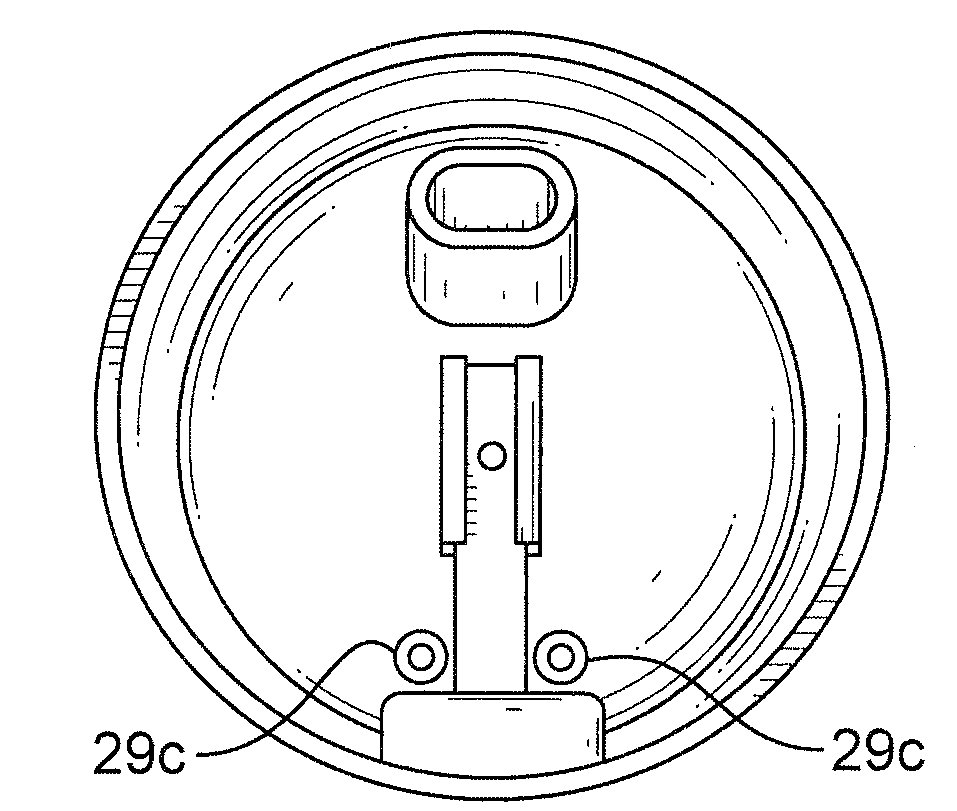

[0022]As shown in FIGS. 2-4, the bottom 50 may include an outer cylindrical wall 52 having an outer thread 53, closed at one end by a bottom wall 54, and an upper flange 55 extending from open end of the outer cylindrical wall 52. A flexible gasket 57 may be deformably mounted over a lip 58 extending from the bottom wall 54, which forms a water-tight seal when engaged with an appropriate mug. An intermediate cylindrical wall 60 and an inner cylindrical wall 62 joined to the bottom wall 54 encircle a valve shaft aperture 64 located in the central region of the bottom wall 54. An oval wall 66 spaced between the intermediate cylindrical wall 60 and the outer cylindrical wall 52 defines a drink passage seat 68...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com