Multifunctional rotatable tool storage device

a multi-functional, tool technology, applied in the field of multi-functional rotatable tool storage devices, can solve the problems of insufficient space utilization of these methods, waste of valuable space in an already crowded garage or tool shed that could be used for other purposes, and inappropriate use of garden implement storage devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

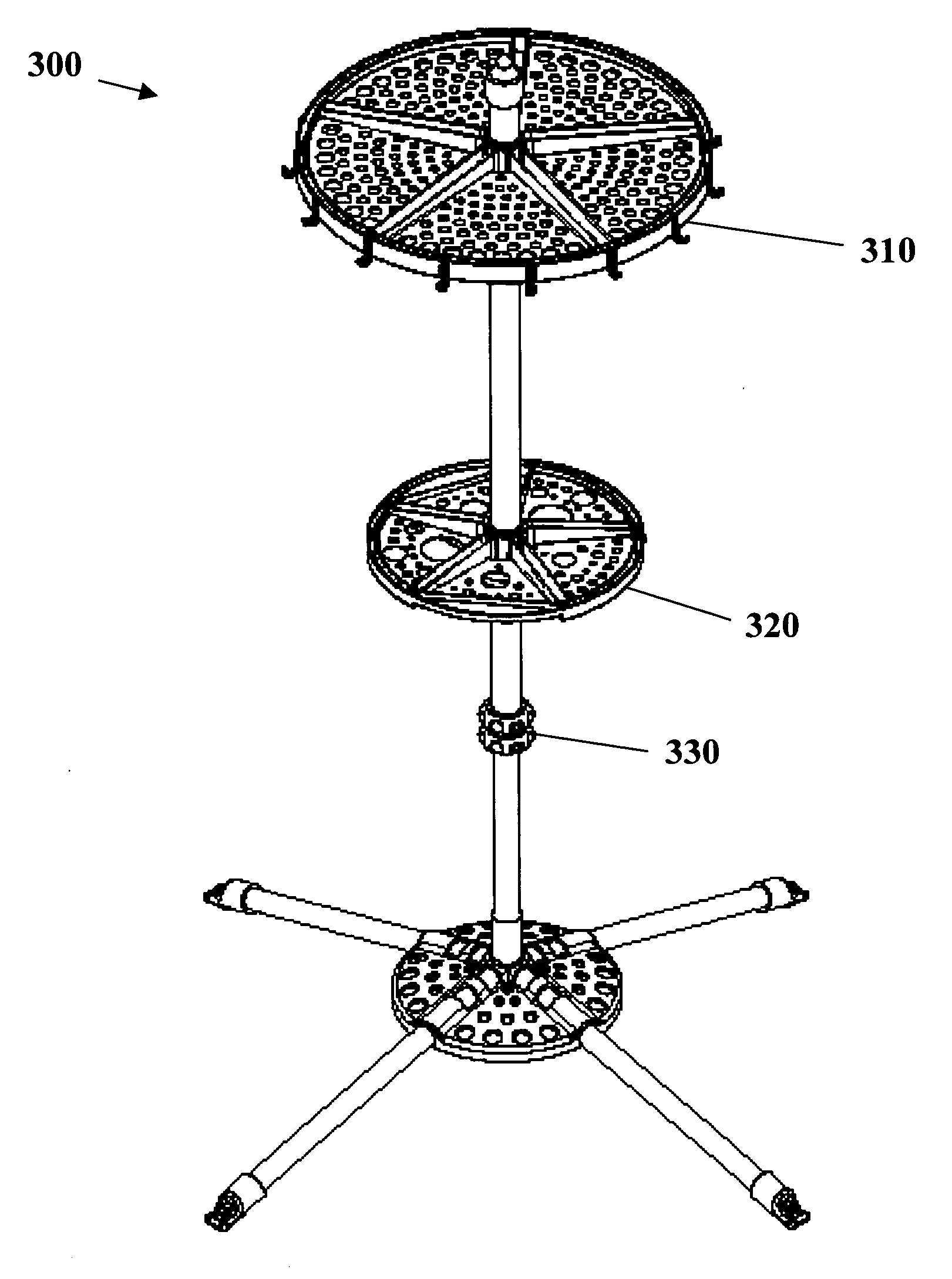

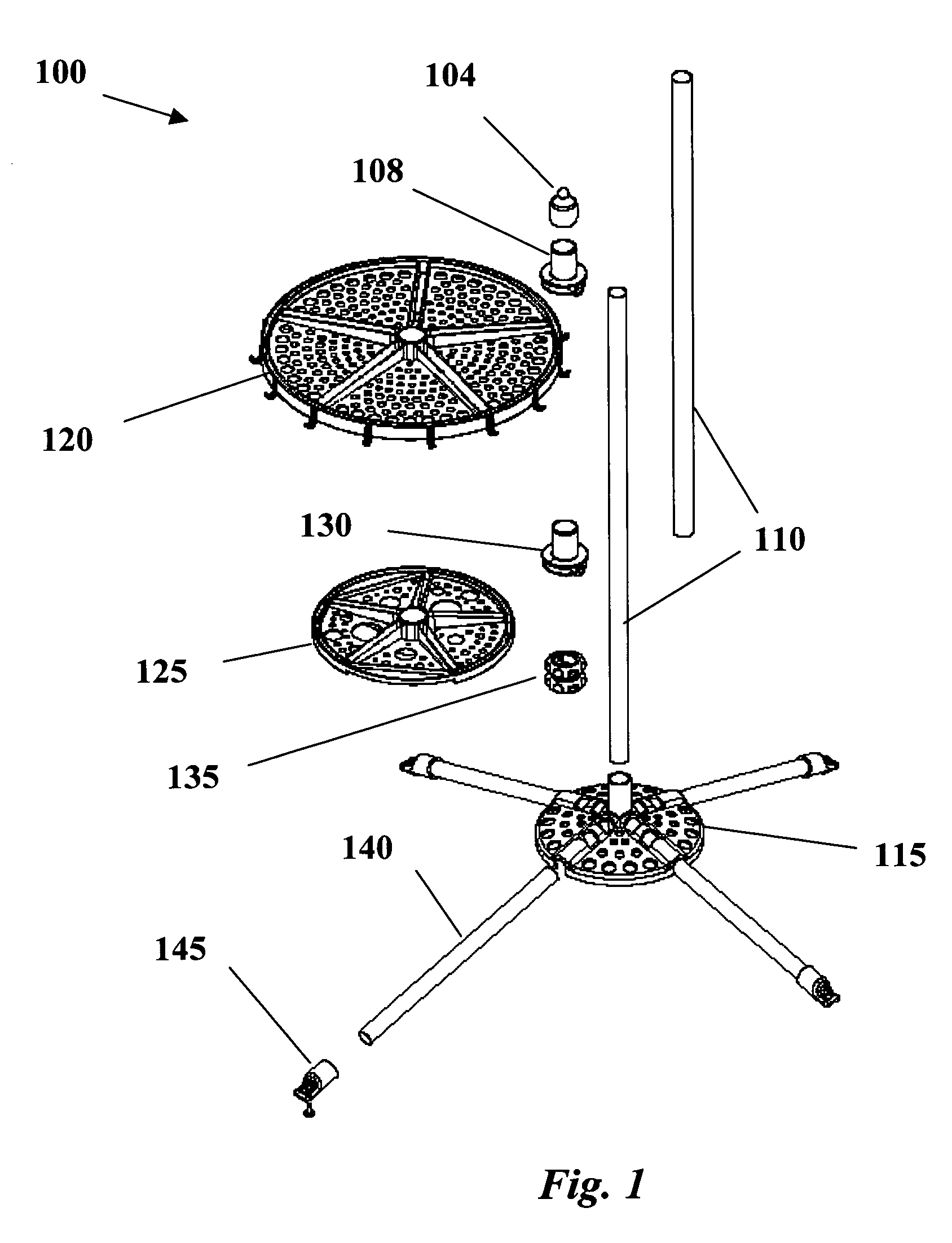

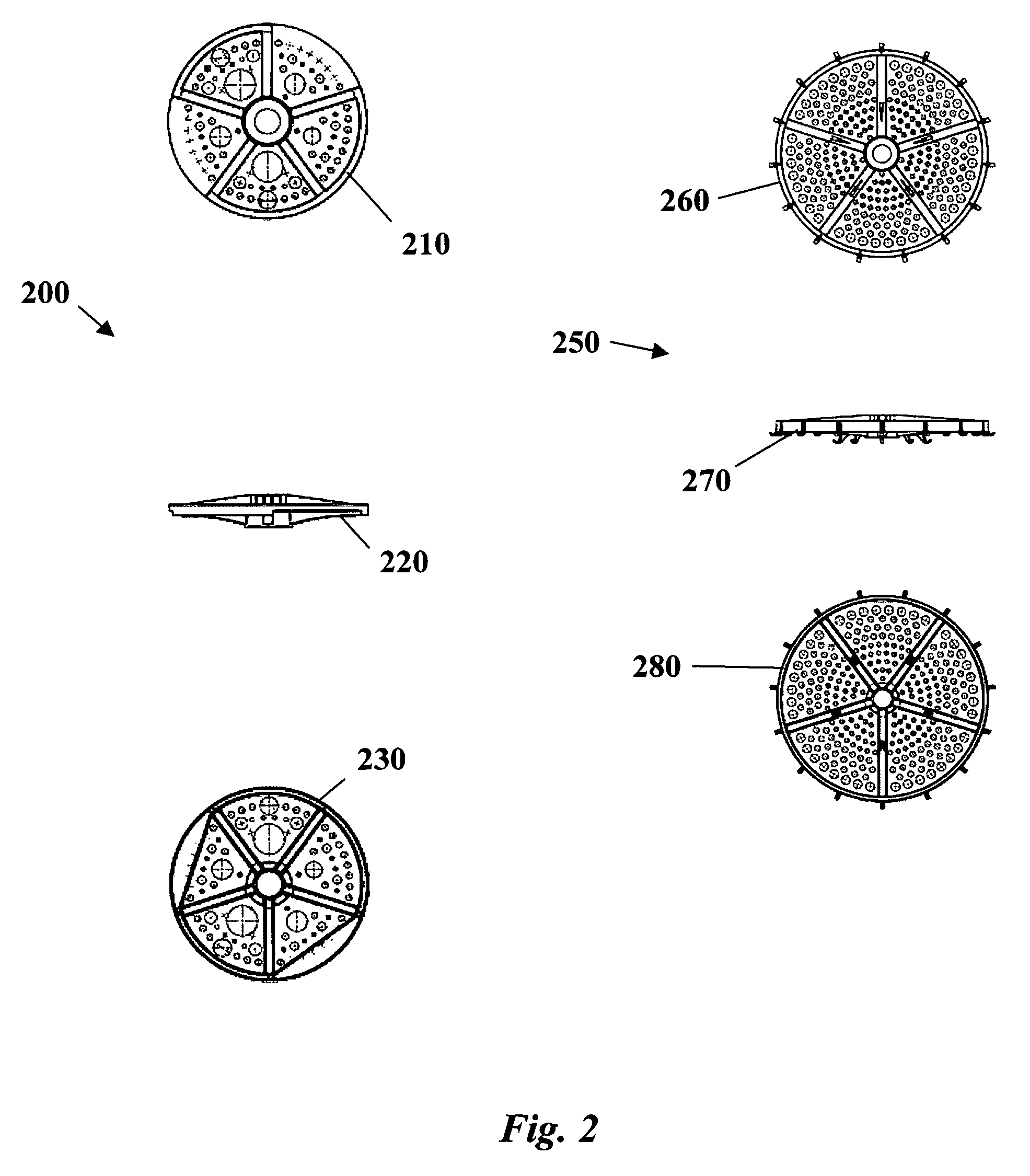

[0021]FIG. 1, numeral 100, shows the elements of the instant invention in a floor model. Concentric tubes 110 are of two different diameters and one slides into the other to create a telescopic shaft. A first table 120 and second table 125 are shown that have a central hole for insertion of the tubes of the telescopic shaft. Both tables are rotatable. Flange spindles 108 and 130 are used to position the first and second table in place on the shaft. In addition a stop collar 135 fits over the telescopic shaft to control the extension length of the shaft. One possible mobile floor stand design 115, with legs 140 and leg levelers 145 accepts one end of the telescopic shaft. A decorative end cap 104 is used on the top of the telescopic shaft. This combination of tables, tubes, flange spindles, and stop collar can be used to generate a variety of configurations for storage possibilities for a floor mounted unit.

[0022]FIG. 2 shows the two tables from FIG. 1 in more detail and from differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com