Automated three dimensional warehouse

a three-dimensional warehouse and automated technology, applied in the direction of transportation and packaging, loading/unloading, storage devices, etc., can solve the problems of under-utilization, one of the shipping or receiving devices may be at full capacity or suffer insufficient capacity, and the receiving sequence becoming a single cycl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

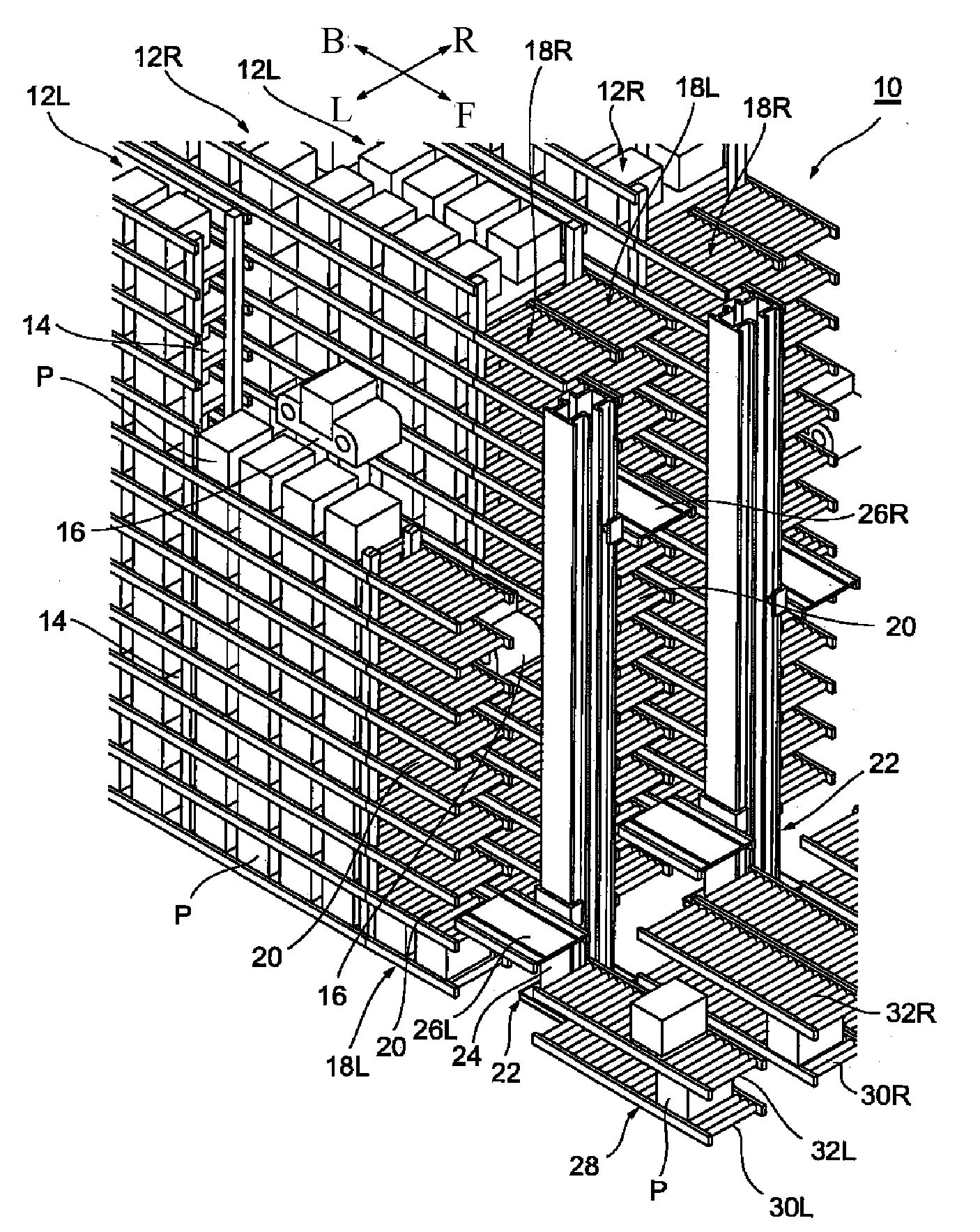

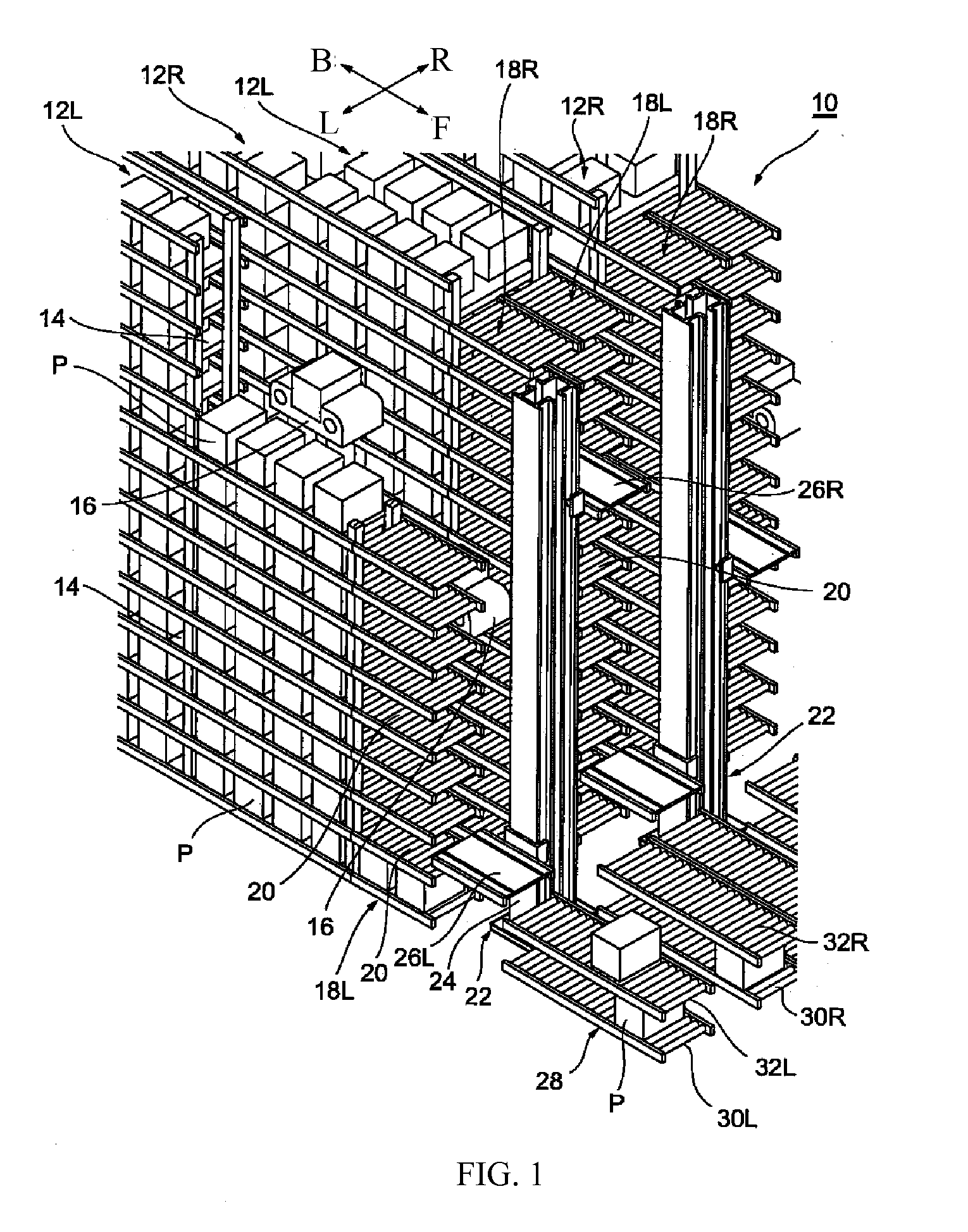

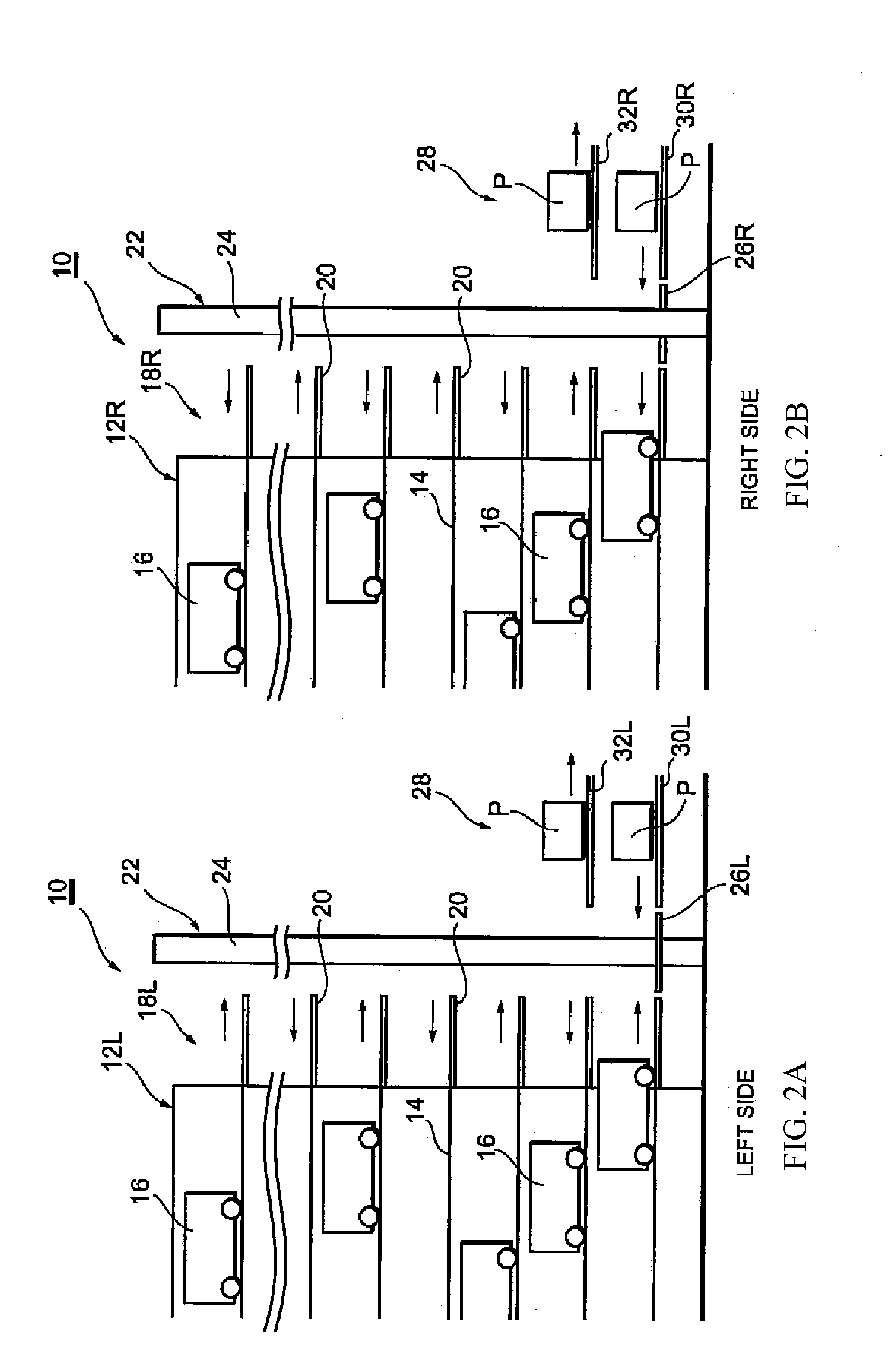

[0036]FIG. 1 is a perspective drawing of a three dimensional automated warehouse10 according to a first embodiment. As shown in the figure, the three dimensional automated warehouse 10 contains at least one pair of left and right layered stacked racks 12L and 12R. Each of the layered stacked racks 12L and 12R contain multiple layers (5 to 20, to be concrete) of shelves oriented in the same horizontal direction (front and back in FIG. 1). The layered stacked racks 12L and 12R, forming a pair, are oriented parallel to each other and separated by a given distance in between.

[0037]A transferring shuttle 16, that is mobile in the horizontal direction along the shelves 14, is implemented between the layered stacked racks 12L and 12R for each layer. The transferring shuttle 16, whose detail is not shown in the drawing, is equipped with a running platform, which can contain a package P on its mid section; a pair of arms installed in the front and back of the running platform, which can exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com