Golf club head

a golf club and head technology, applied in the field of golf club head, can solve the problems of complicated design of enhanced head head, and achieve the effect of excellent hitting sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0138]Hereinafter, the effects of the present invention will be clarified by examples. However, the present invention should not be interpreted in a limited way based on the description of the examples.

[Preparation of Simulation Head Data]

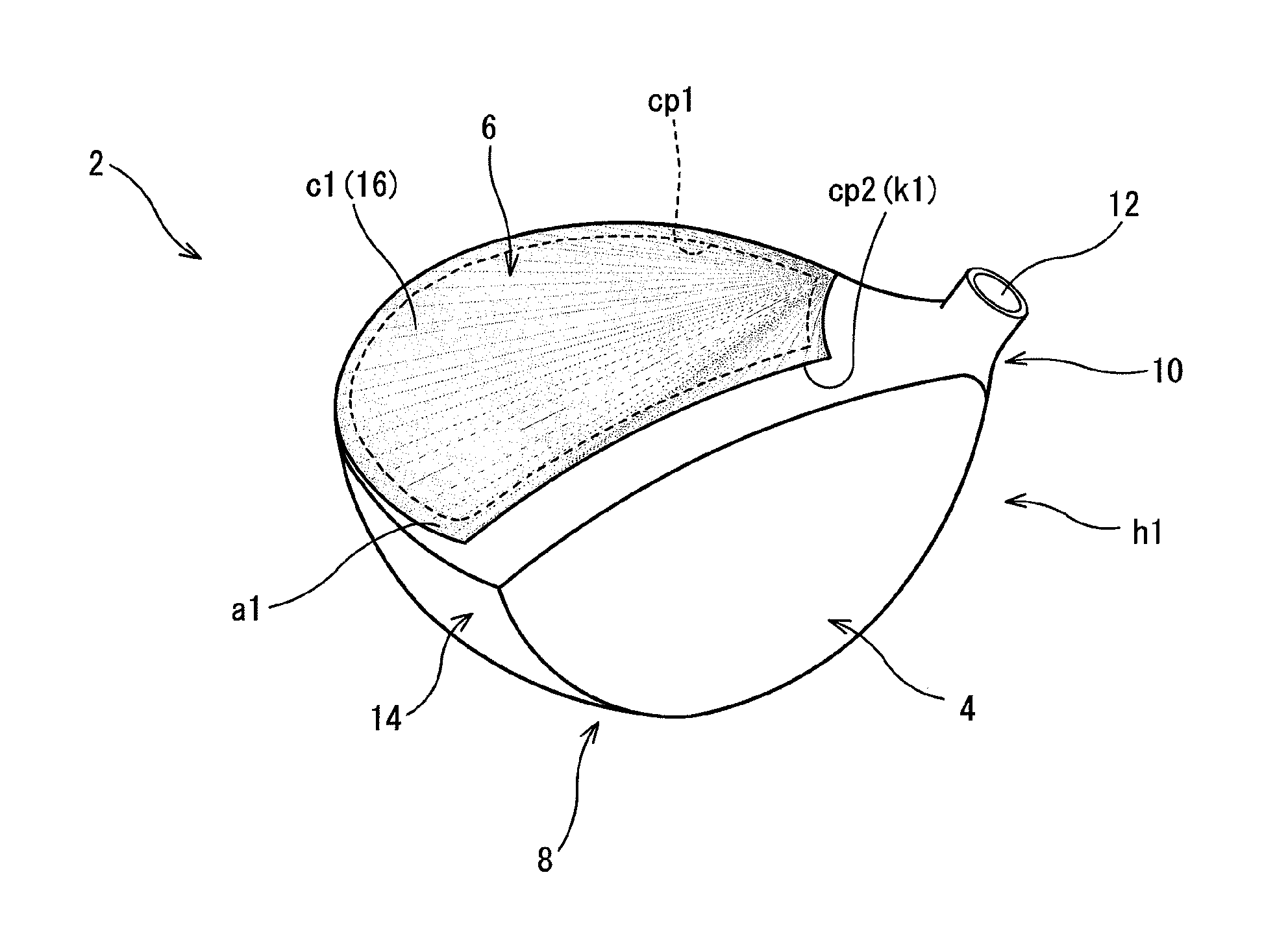

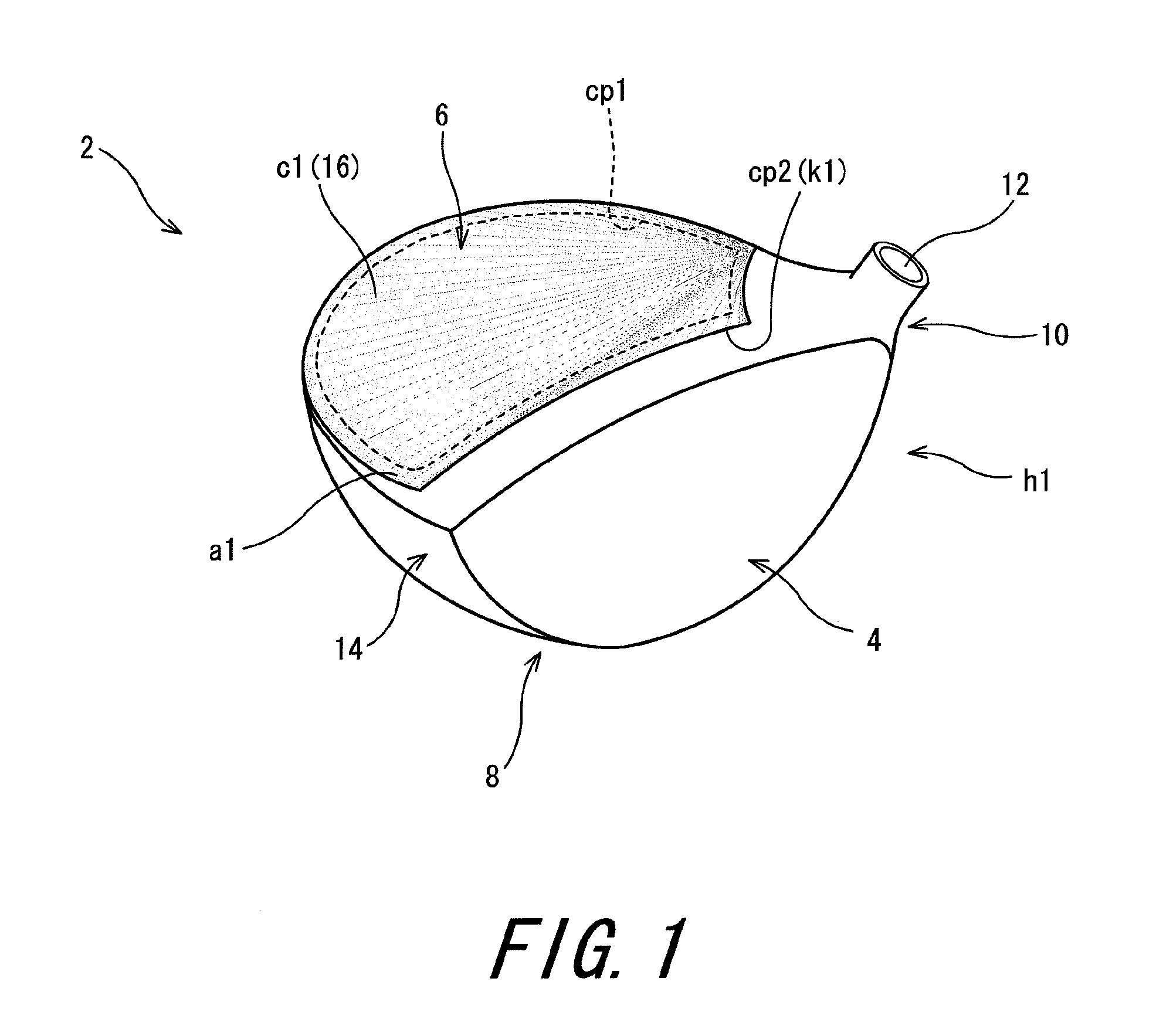

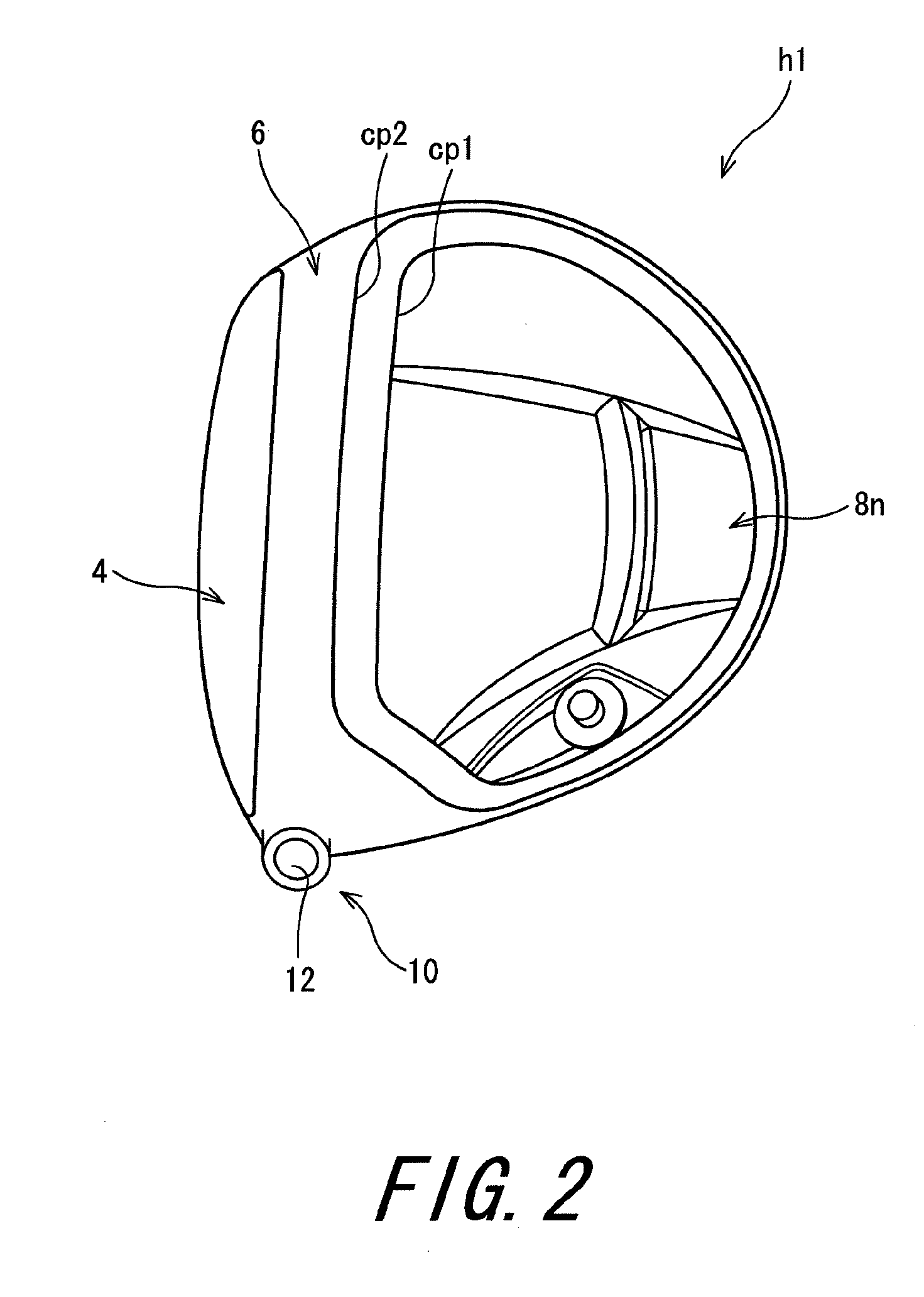

[0139]The three-dimensional data of a head shown in FIGS. 1 and 2 was prepared. The volume of the head was set to 449 cc, and the weight of the head was set to 178 g. The head was mesh-divided into a finite element using a commercially available preprocessor (HyperMesh or the like) to obtain a calculation model. FIG. 6 is a plan view of the mesh-divided head. FIG. 7 is a bottom view of the mesh-divided head. A portion painted in black in a crown of FIG. 6 shows a CFRP member. FIG. 8 is a plan view of the mesh-divided head as in FIG. 6. Unlike FIG. 6, in FIG. 8, the CFRP member is not painted in black. In FIG. 8, the position of the crown opening cp1 is shown by a thick line. The inner side of the crown opening cp1 is the CFRP single part.

[0140]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com