Wireless communication between tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

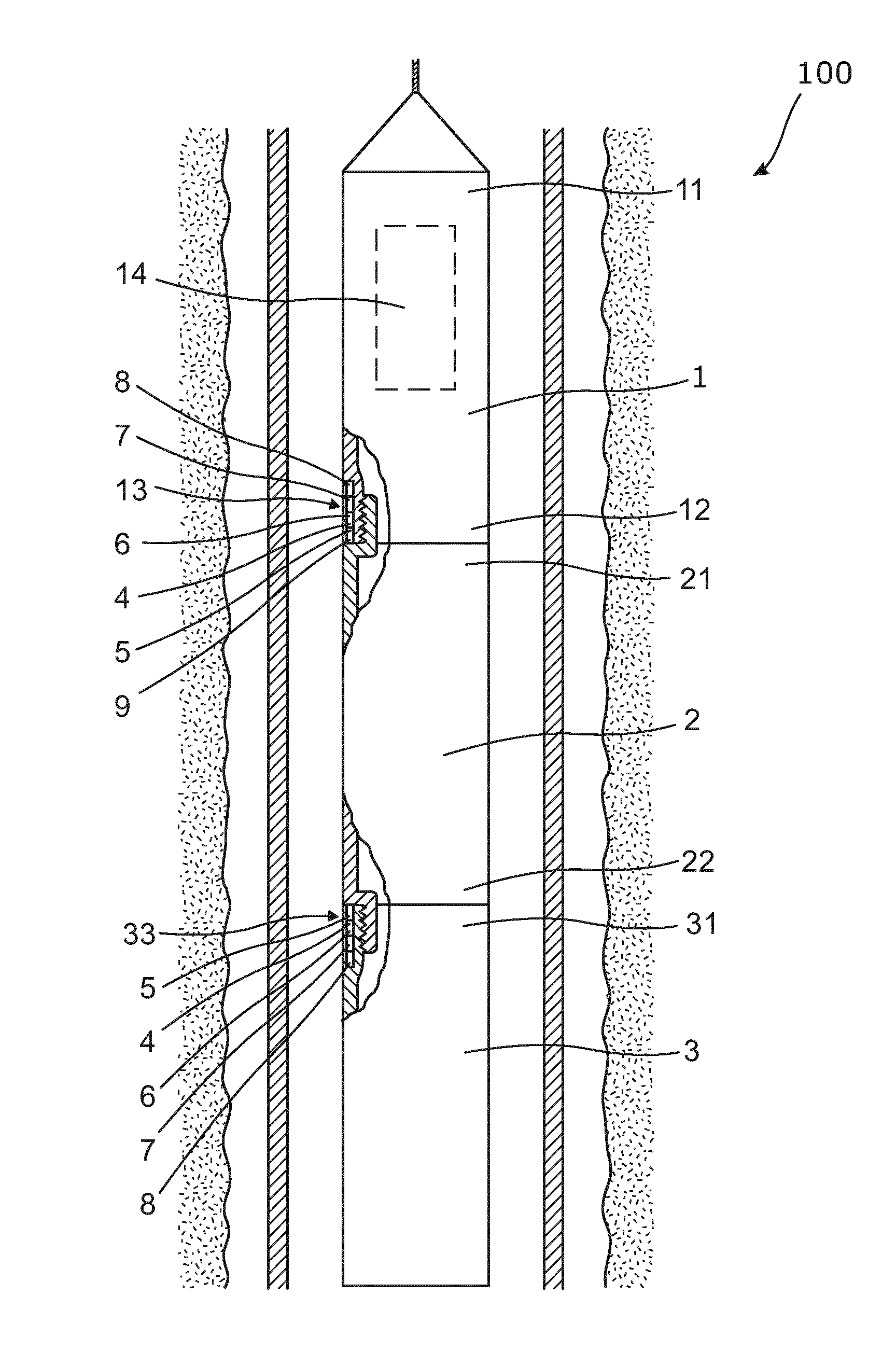

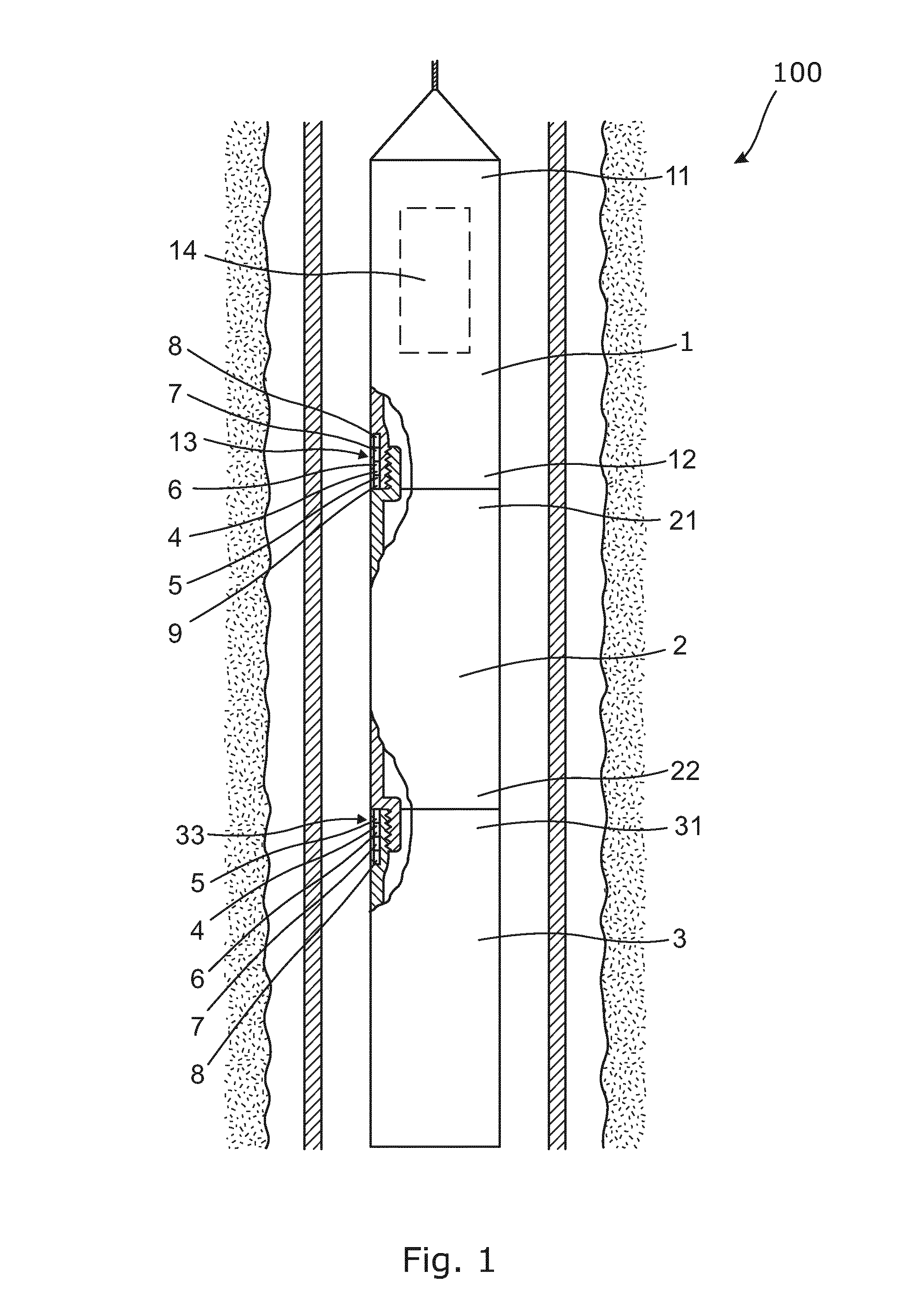

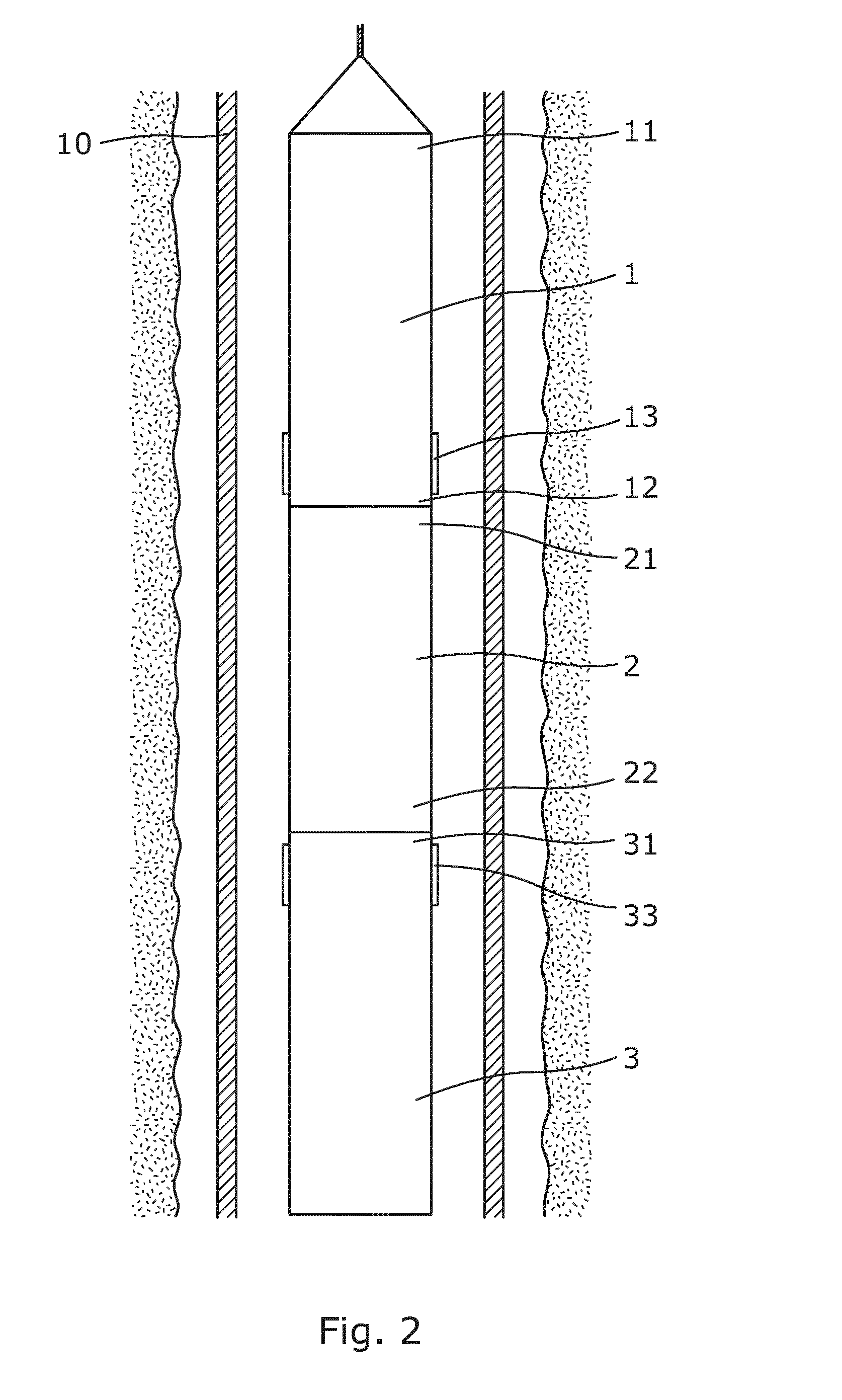

[0059]FIG. 1 shows a downhole tool system 1 comprising three tools; a first 1, a second 2 and a third 3 tool, arranged as a tool string. The first tool 1 is connected to a wireline at its first end 11 to power the tool string. In its second end 12, the first tool 1 is connected to a first end 21 of the second tool 2 by means of a threaded connection firmly connecting the first 1 and second 2 tools. In its second end 22, the second tool 2 is connected to a first end 31 of the third tool 3, also by means of a threaded connection.

[0060]Two operators may work together to perform a well operation in the sense that a tool of one operator is arranged between the tools of another operator. Thus, the first 1 and the third tool 3 come from a first operator and the second tool 2 comes from a second operator. Since the first 1 and third 3 tools are separated by the second tool 2, communication between the tools of the first operator cannot take place inside the tools in the conventional way sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com