Fiber orienting technology for a grinding machine

a technology of fiber orienting and grinding machine, which is applied in the field of fiber orienting technology for grinding machine, can solve the problems of poor quality of meat, dead spots and turbulence in the meat flow, and achieve the effects of less myosin activity, less myosin release and mixing, and better bite/binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

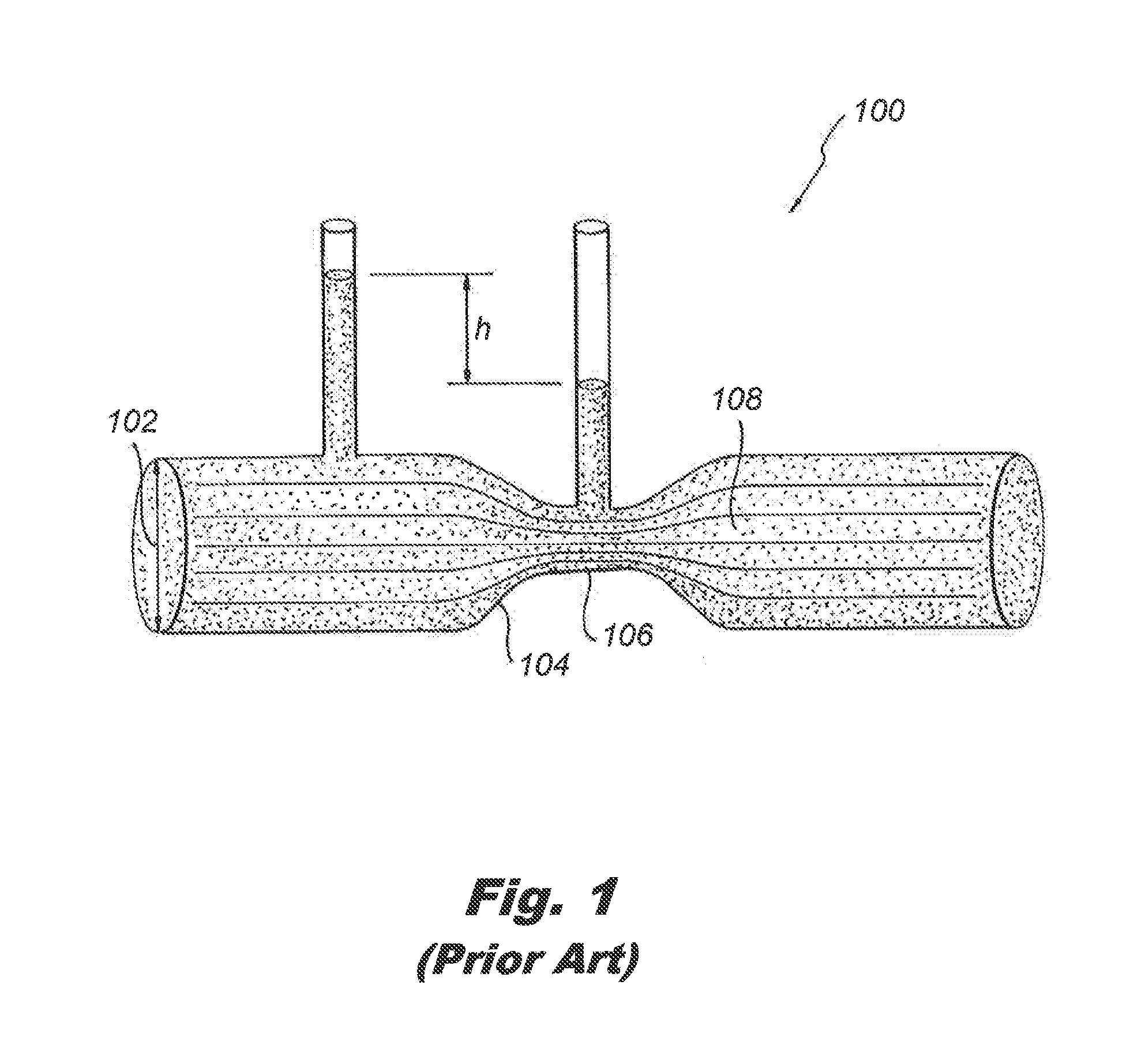

[0044]FIG. 1 shows a prior art venturi 100 comprising a diameter 102 angle transition 104, throat length 106 and discharge 108.

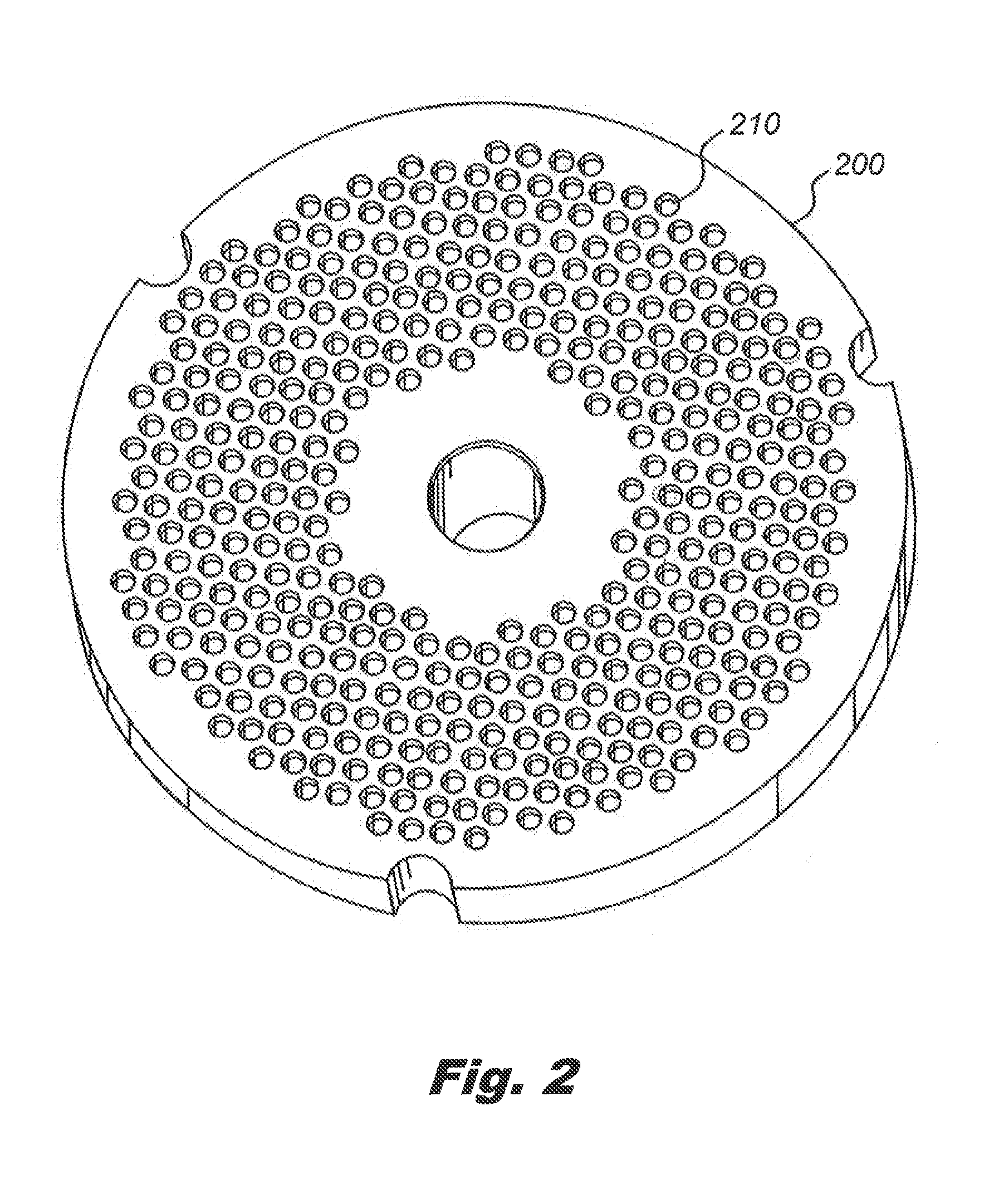

[0045]FIG. 2 shows an orifice plate 200 having apertures 210.

[0046]FIG. 3 shows a magnified view of the orifice plate 200 showing the apertures 210.

[0047]FIG. 4 shows the orifice plate 200 having the apertures 210. The apertures comprising a sphere section 212 and a cylinder section 214.

[0048]FIG. 5 shows a magnified view of the apertures 210 having a spherical section 212 and a cylinder section 214.

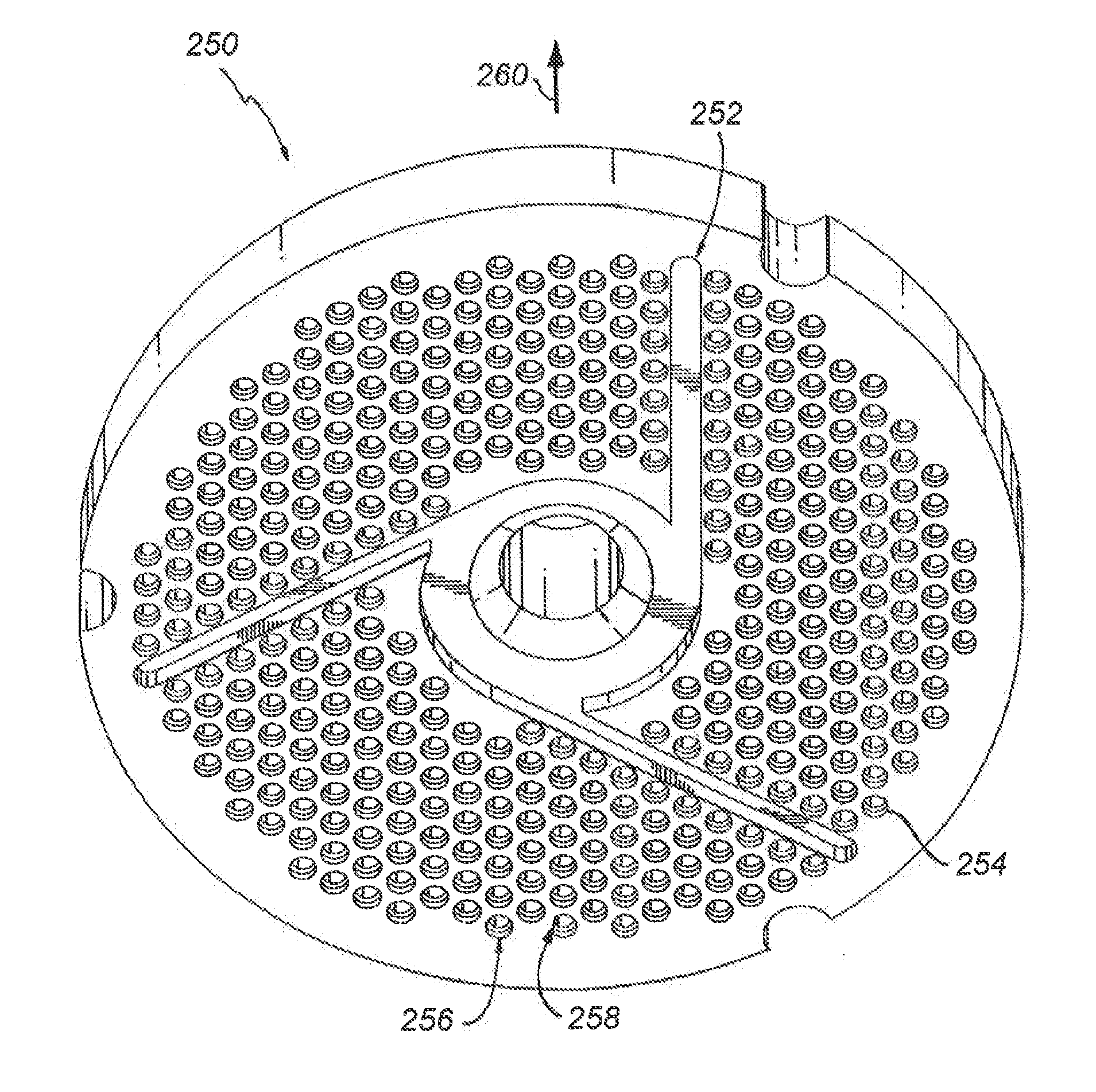

[0049]FIG. 6 shows a grinder plate 250 having a bone collection slots 252, and orifices 254 which are comprised of a spherical diameter 256 and a cylindrical diameter 258. The arrow 260 shows the direction of the meat flow.

[0050]FIG. 7 shows a bone collector tube 270 which is comprised of a waste tube 272, waste auger 274, FOT bone extraction insert 276 which is comprised of a spherical section 278 and a cylindrical section 280.

[0051]The present invention relates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com