Lacrosse head to handle attachment

a technology for lacrosse and handle attachment, which is applied in the field of lacrosse equipment, can solve the problems of poor head to handle attachment, difficult screw installation, and loose attachment of the head to the handle at the first, and achieve the effect of reducing the risk of loosening over tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. Overview

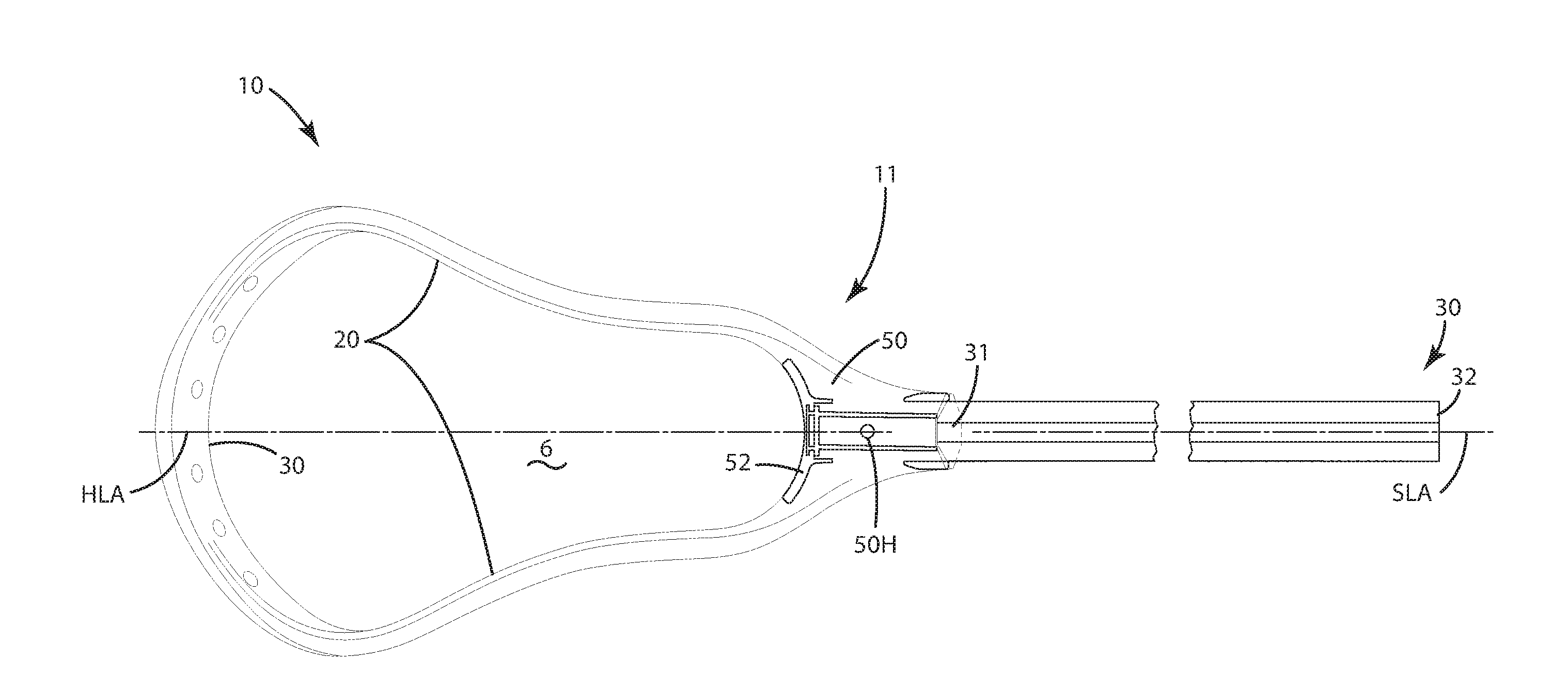

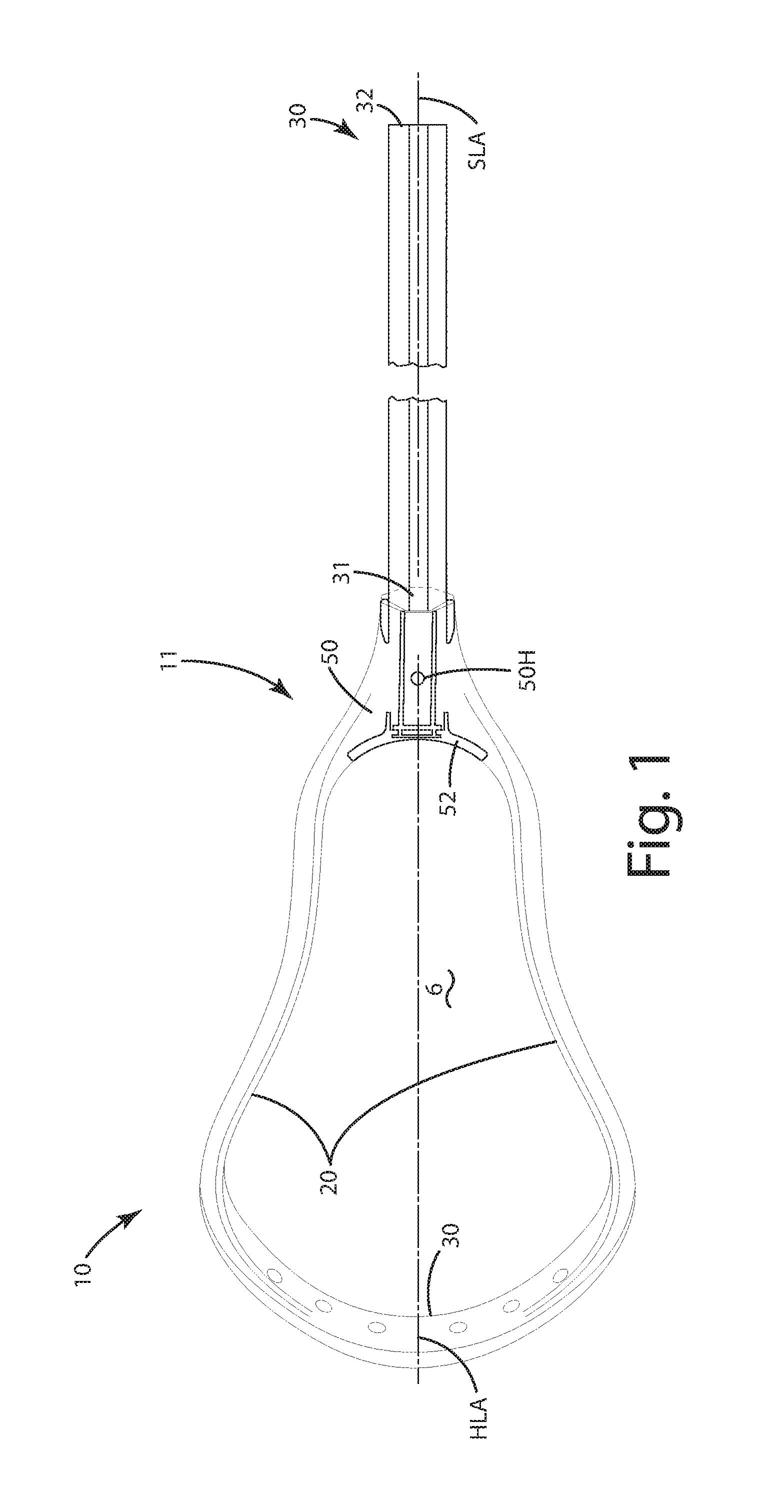

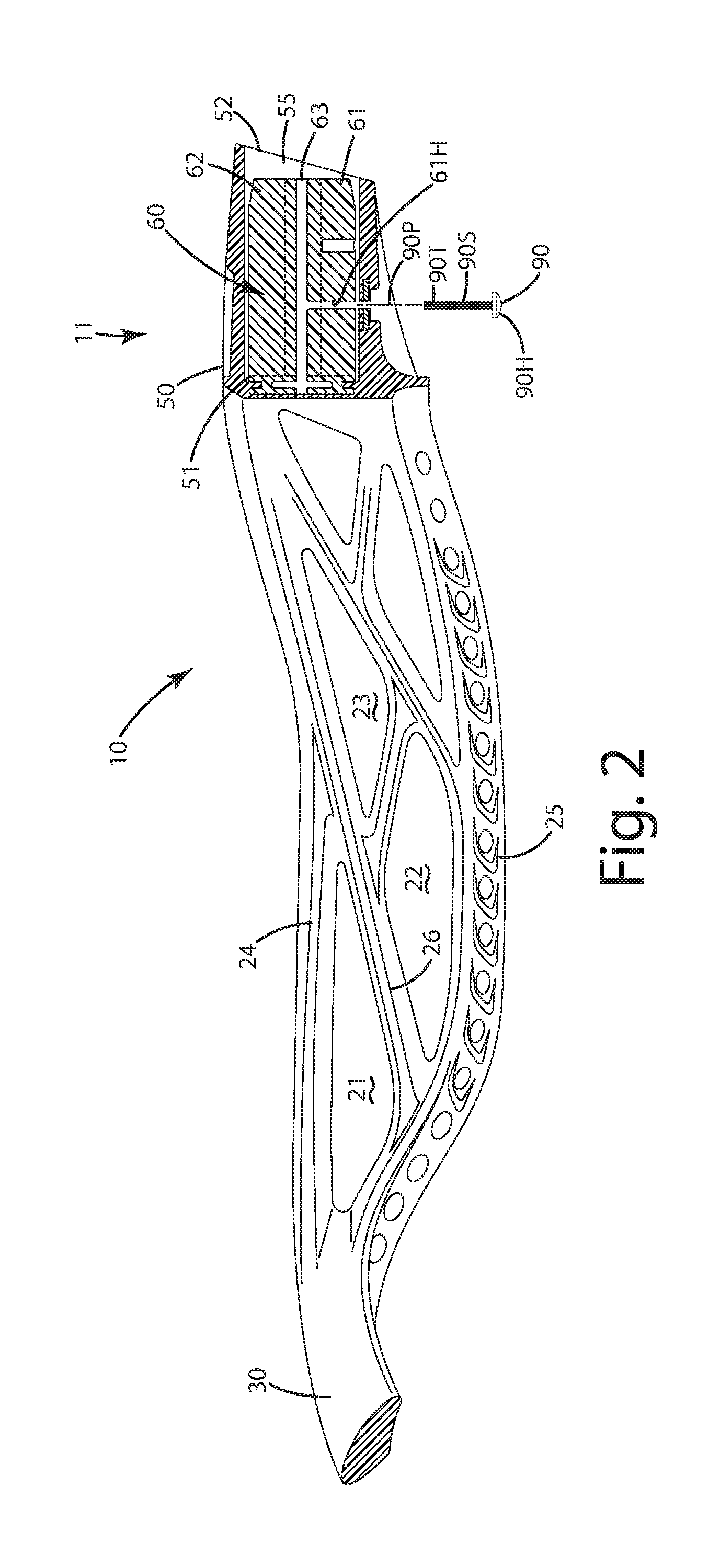

[0031]A lacrosse head of a current embodiment is shown in FIGS. 1-8 and generally designated 10. The lacrosse head 10 is attached to a lacrosse handle 30. The lacrosse head 10 can include a pair of opposing sidewalls 20 and a scoop 30 connecting the pair of opposing sidewalls 20. Located at the lower portion of the head, generally within a throat 11, is a base 50 which includes a ball stop portion 52 facing inwardly toward the ball receiving area 6. The sidewalls 20 can be of an open frame construction, that is, they can define at least one non-string hole that extends completely through the sidewalls, from the interior to the exterior, where the non-string hole reduces the weight of the head. Exemplary non-string holes are the frame holes 21, 22 and 23 shown in FIG. 2.

[0032]The sidewalls, base and scoop can circumferentiate or surround and form a periphery about the ball receiving area 6 of the head. This ball receiving area 6 of the head includes surfaces of the head th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com