Palladium-aluminium oxide catalyst and its preparation process

A technology of alumina and catalyst, applied in the field of palladium-alumina catalyst and its preparation, can solve problems such as complicated operation process and questionable firmness of palladium plating layer, and achieve the goal of reducing the thickness of Pd layer, saving cost and reducing the amount of Pd Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

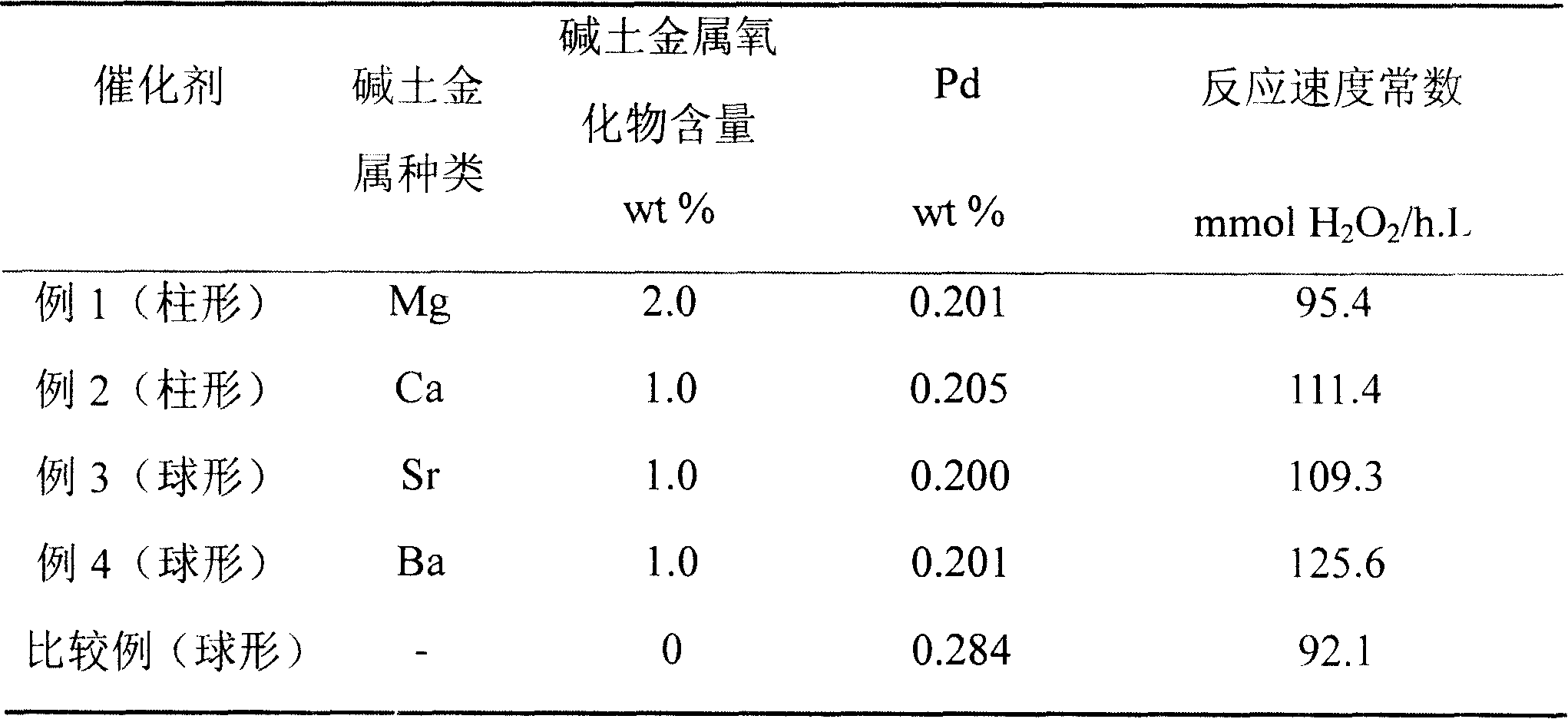

Examples

preparation example Construction

[0010] The preparation method of the catalyst of the present invention is prepared by an impregnation method at normal temperature (10-45° C.), and is characterized in that the preparation process includes the following steps: (a) impregnating the alumina support with an alkaline earth metal nitrate or acetate solution, and Convert alkaline earth metal salts into oxides at a temperature of 500-995°C (depending on the starting crystal phase of the alumina used); (b) add an appropriate amount of palladium chloride and an equal weight of sodium chloride (or take the molar amount of sodium and palladium) Sodium chloride and palladium chloride with a ratio of 2:1) are dissolved in water to form sodium chloride palladium (NaCl 2 PdCl 4 ) aqueous solution, the temperature of the immersion solution is about 10-45°C; (c) a certain amount of dry pre-coated alkaline earth metal oxide with a BET surface area of 60-130m 2 / g of alumina is added to the sodium chloride palladium solution,...

Embodiment 1

[0017] Weigh 30g γ-Al 2 o 3 As a carrier, its shape and size are φ3×5-20 (mm) columnar, impurity Na 2 O2 / g in a 250ml glass beaker. Mix 18ml evenly. will absorb Mg(NO 3 ) 2 The alumina after the aqueous solution is placed in an oven at about 80-120°C for dehydration for about 60 minutes, then transferred to a high-temperature furnace and calcined at 900-995°C for ~10 hours in the atmosphere, and then lowered to room temperature. As a benchmark, the loading of MgO on the carrier is about 2%wt.

[0018] Place the alumina carrier after the above treatment in a 250ml glass beaker, and pour 70ml of Na 2 PdCl 4 solution, impregnated for 60 min under slow stirring, and after filtering out the catalyst and draining, washed with deionized water until the washing water was washed with 2% AgNO 3 until no chloride ions were detected in the solution. Filter out the catalyst and drain it, dry it at 80-150°C for about 2 hours and bake it in a high-temperature furnace at 450-550°C i...

Embodiment 2

[0022] Repeat the process of embodiment 1, just the Ca(CH 3 COO) 2 aqueous solution. Based on the weight of the alumina carrier, the weight content of CaO on the carrier is about 1%, the weight content of metal palladium is 0.205%, and the thickness of the palladium layer on the catalyst is 55 μm.

[0023] The catalyst activity was evaluated under the same conditions as in Example 1, and the evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com