Boronizing treatment and heat treatment process of martensitic stainless steel for steam turbine nozzle set

A martensitic stainless steel and treatment process technology, applied in heat treatment equipment, heat treatment process control, metal material coating process and other directions, can solve the problems of difficulty in boron atoms and hinder boron infiltration, to simplify the treatment process and overcome the difficulty in infiltration. The effect of boron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

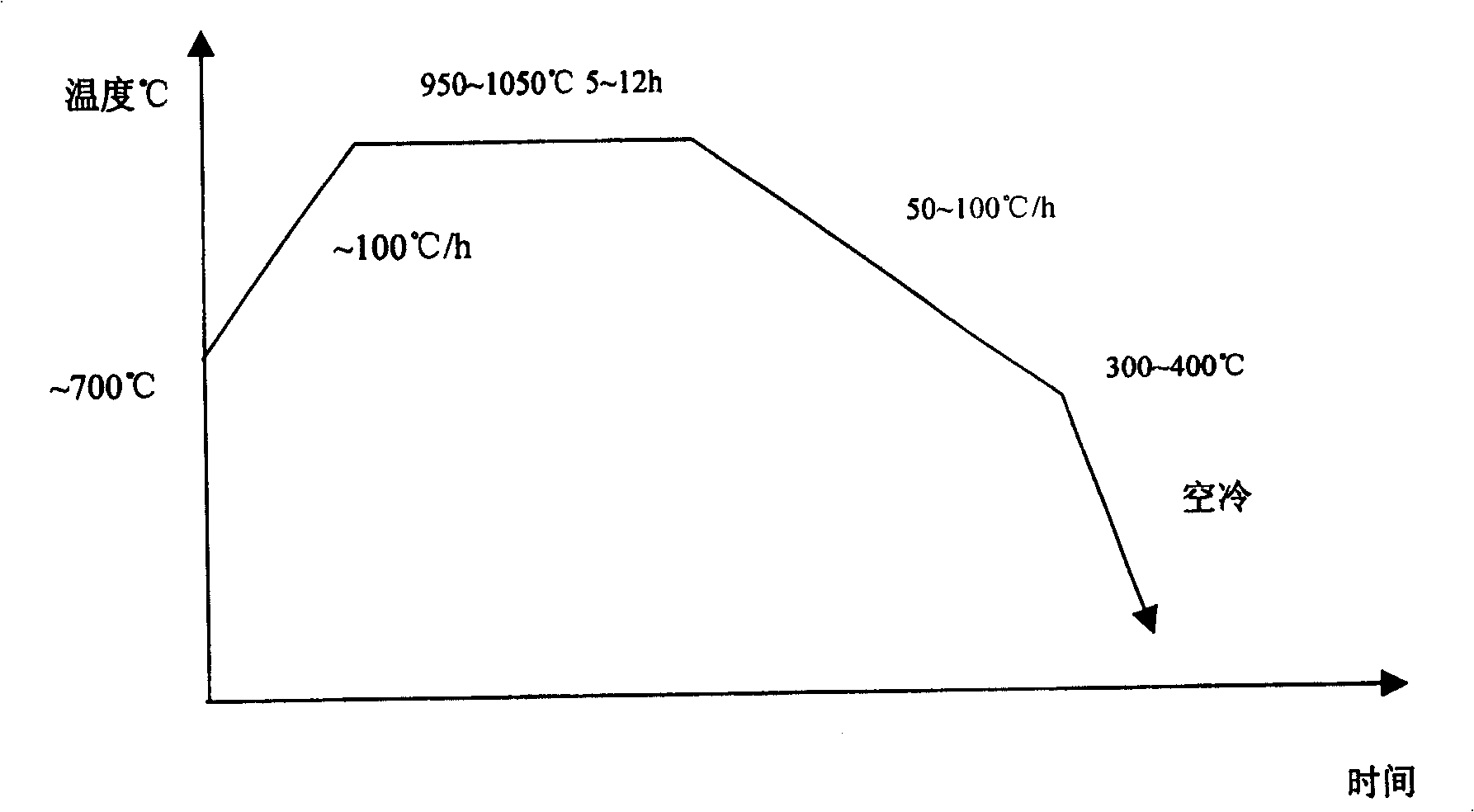

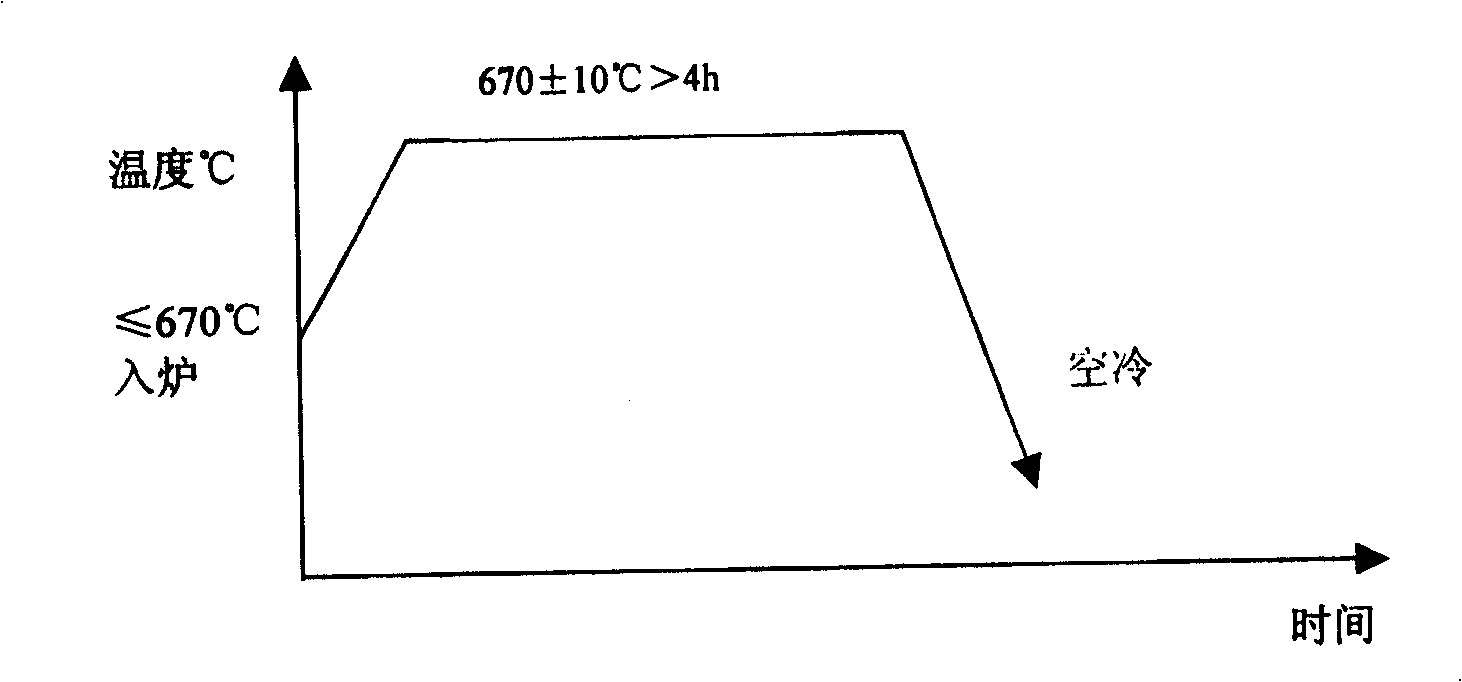

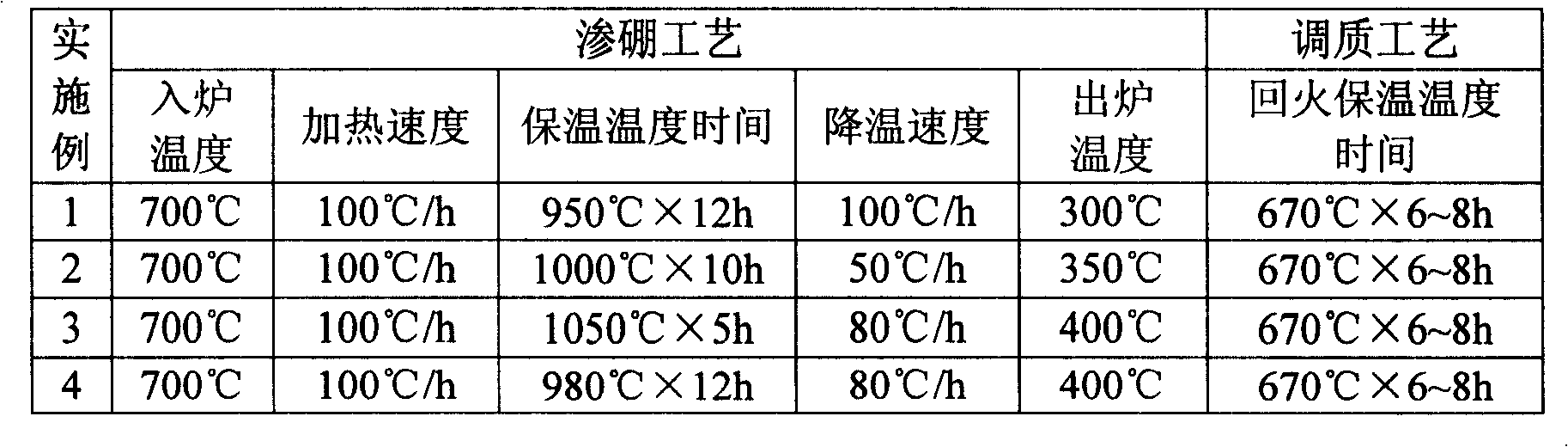

[0031] Table 1 shows the experimental data of the embodiment of the martensitic stainless steel boriding treatment process and quenching and tempering (tempering) heat treatment process for the steam turbine nozzle group.

[0032] Table 1

[0033]

[0034] Table 2 is the boronizing layer detection and matrix material detection data of the embodiment.

[0035] Table 2

[0036]

[0037] After analyzing the detection data of the embodiment, it can be obtained that: after the martensitic stainless steel used for the nozzle group of the steam turbine undergoes the boronizing process, the boronizing depth reaches 0.08-0.14mm, and the boronizing layer hardness is HV 100g : 1500~1900, boronizing layer structure is FeB Fe 2 B compound. At the same time, the performance (hardness, strength, plasticity, structure, etc.) of the matrix structure of the nozzle group material is within the scope of the original quenching and tempering treatment performance requirements. As a result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com