Ferroelectric ceramic micro refrigerator and producing method thereof

A technology of ferroelectric ceramics and micro-refrigerators, which is applied in the directions of refrigerators, refrigeration and liquefaction, machine operation mode, etc. Area of thin slices, etc., to achieve the effect of convenient cooling/heat conversion, enhanced optional work, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

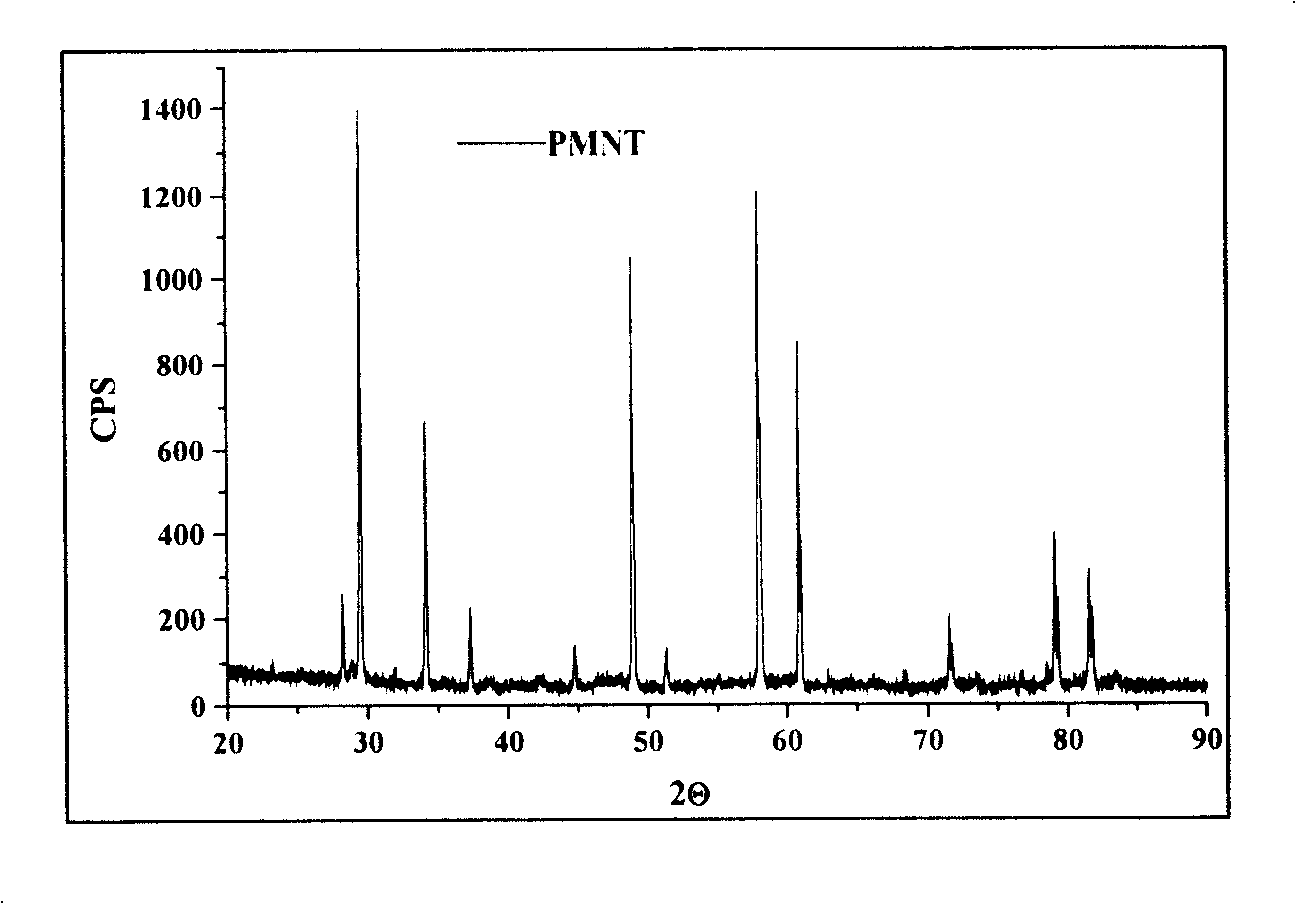

[0060] Embodiment 1: to analyze pure Pb (C 2 h 3 o 2 ) 2 Powder, chemically pure Ti(OC 4 h 9 ) 4 Solvent and Mg(C 2 h 3 o 2 ) 2 and electron pure Nb 2 o 5 Powder, etc. as raw materials, according to Pb (Mg 1 / 3 Nb 2 / 3 )O 3 with PbTiO 3 A formulation with a mol ratio of 85 / 15, with an excess of 4 mol% of Mg and 5 mol% of Pb. First, the above-mentioned PMNT raw materials meeting the stoichiometric ratio are miscible in an organic solvent of ethylene glycol ether to obtain a white sol. The sol is put into a ball mill jar and fully ball milled for 8 hours. At this time, various raw material components are mixed at a molecular level to obtain a PMNT precursor. The PMNT precursor was placed in an infrared oven to fully dry and gel at 120°C, and then placed in a resistance furnace for pre-calcination at 450°C and 750°C for 2 hours respectively to obtain PMNT pre-crystallized powder. The PMNT pre-crystallized powder is pressed into a green body with a mold at 120Mpa; f...

Embodiment 2

[0061] Embodiment 2: to analyze pure Pb (C 2 h 3 o 2 ) 2 Powder, chemically pure Ti(OC 4 h 9 ) 4 Solvent and Mg(C 2 h 3 o 2 ) 2 and electron pure Nb 2 o 5 Powder, etc. as raw materials, according to Pb (Mg 1 / 3 Nb 2 / 3 )O 3 with PbTiO 3 A formulation with a mol ratio of 85 / 15, with an excess of 6 mol% of Mg and 8 mol% of Pb. First, the above-mentioned PMNT raw materials meeting the stoichiometric ratio are miscible in an organic solvent of ethylene glycol ether to obtain a white sol. The sol is put into a ball mill jar, and is fully ball milled for 10 hours. At this time, each raw material component is mixed at a molecular level to obtain a PMNT precursor. The PMNT precursor was placed in an infrared oven to fully dry and gel at 180°C, and then placed in a resistance furnace for pre-calcination at 490°C and 800°C for 2 hours respectively to obtain PMNT pre-crystallized powder. The PMNT pre-crystallized powder is pressed into a green body with a mold at 160Mpa; f...

Embodiment 3

[0062] Embodiment 3: to analyze pure Pb (C 2 h 3 o 2 ) 2 Powder, chemically pure Ti(OC 4 h 9 ) 4 Solvent and Mg(C 2 h 3 o 2 ) 2 and electron pure Nb 2 o 5 Powder, etc. as raw materials, according to Pb (Mg 1 / 3 Nb 2 / 3 )O 3 with PbTiO3 A formulation with a mol ratio of 85 / 15, with an excess of 5 mol% of the Mg component and 7 mol% of the Pb component. First, the above-mentioned PMNT raw materials meeting the stoichiometric ratio are miscible in an organic solvent of ethylene glycol ether to obtain a white sol. The sol is put into a ball mill jar and fully ball milled for 9 hours. At this time, each raw material component is mixed at a molecular level to obtain a PMNT precursor. Put the PMNT precursor into an infrared oven to fully dry and gel at 160°C, then put it into a resistance furnace and pre-fire it at 470°C and 800°C for 2 hours respectively to obtain PMNT pre-crystallized powder. The PMNT pre-crystallized powder is pressed into a green body with a mold at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com