Unitized bearing assembly

A technology of bearing assembly and bearing box, applied in the field of roller bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

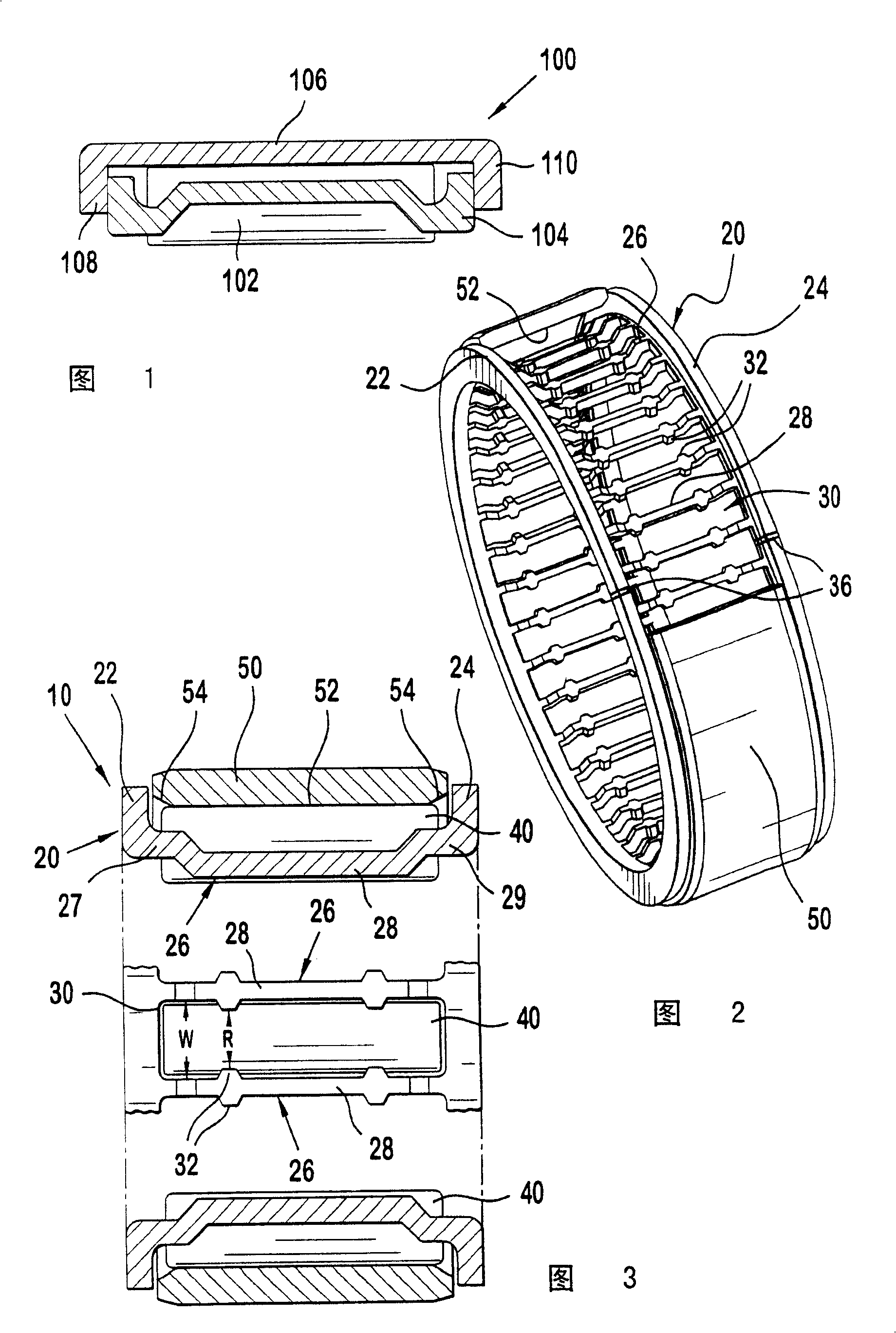

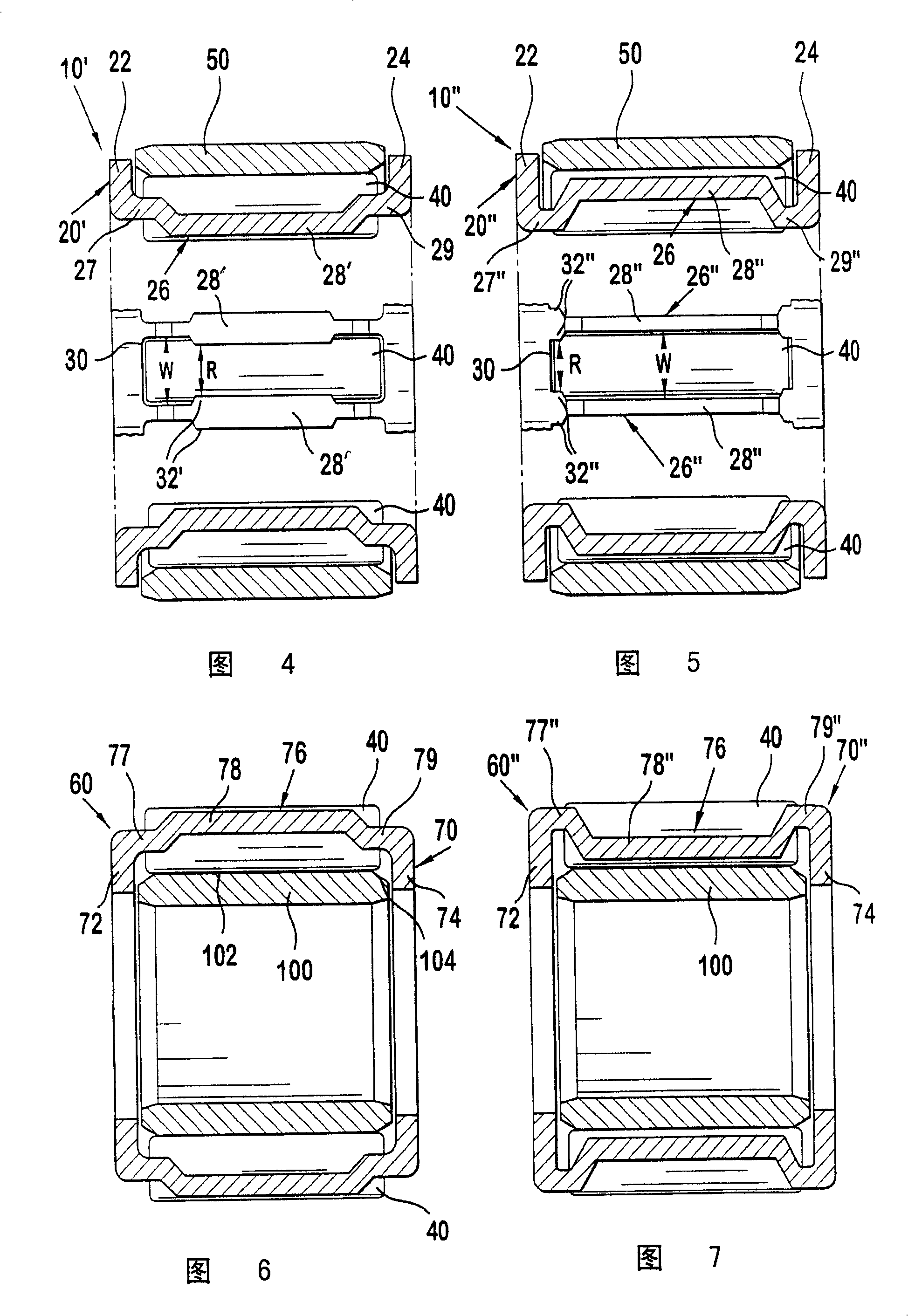

[0012] Referring to Figures 2 and 3, a bearing assembly 10 according to a first specific embodiment of the present invention is described. The bearing assembly 10 generally includes a bearing cartridge 20 , a plurality of rollers 40 and a sleeve 50 . The bearing cartridge 20 of this embodiment has radial flanges 22 and 24 connected together by a cross arm 26 . Cross arm 26 has a central portion 28 that is offset radially inwardly from laterally outward portions 27 and 29 . Bearing cartridge 20 may be manufactured from a stamped sheet rolled to form a hoop which is then welded, for example at 36 in FIG. 2 . Of course other manufacturing methods can also be used.

[0013] Adjacent spaced apart cross arms 26 define a plurality of roller retention slots or pockets 30 surrounding the bearing cartridge 20 . Each retaining slot or pocket 30 is sized to retain a roller 40 for rotation therein. In this embodiment, the radially inward central portion 28 includes a plurality of circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com