Method of controlling fragmentation and recovery of waste battery and system thereof

A waste battery and recycling method technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve problems such as difficulty in ensuring economic operation, high energy consumption, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

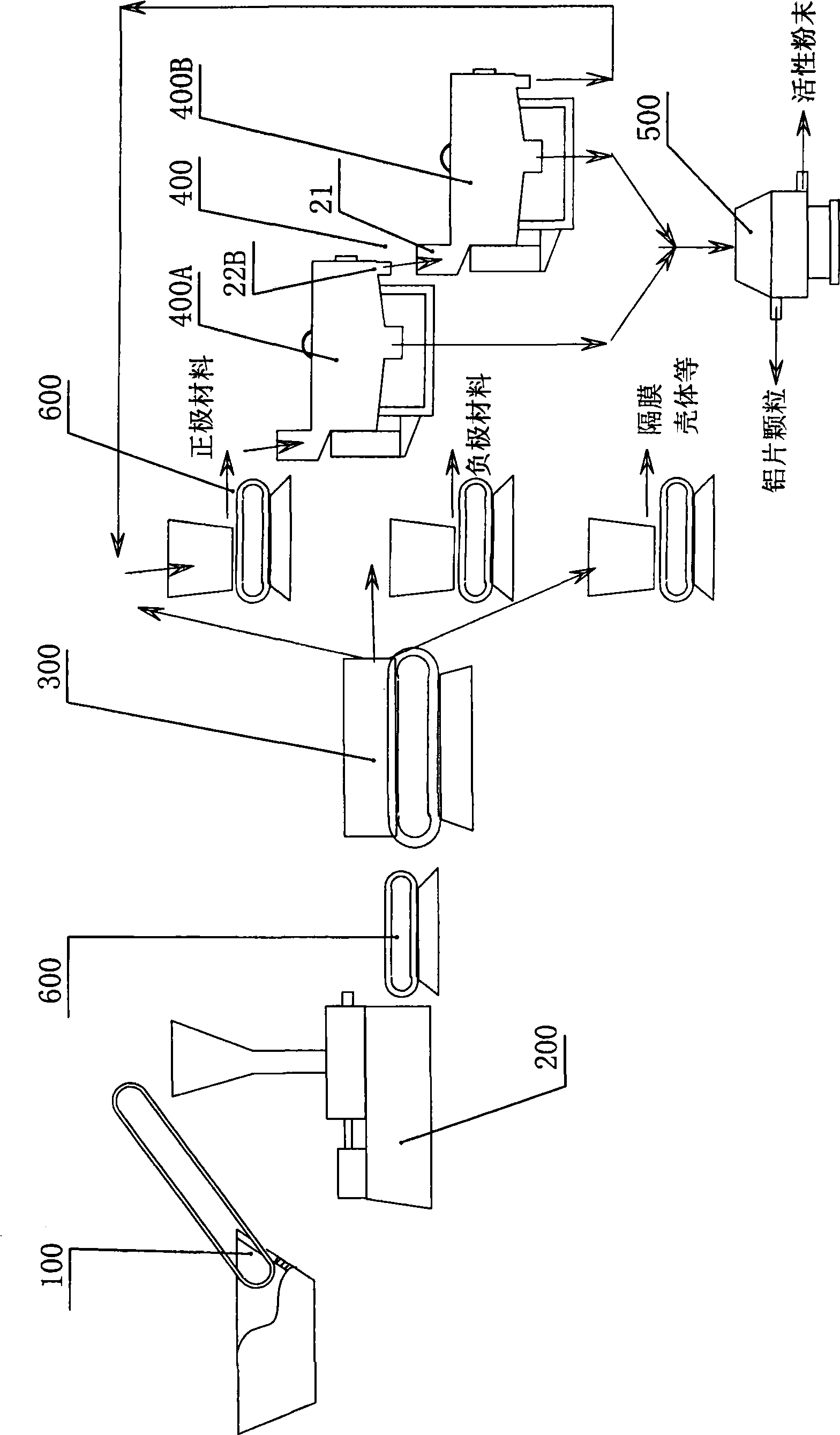

[0026] Embodiment of controlled crushing recovery method:

[0027] An embodiment of the waste battery controlled crushing recovery method of the present invention includes the following steps:

[0028] A) Sorting and categorizing the waste batteries, the sorting and categorization is to use the combination of gravity, magnetic force, shape difference and ray perspective to sort and classify the mixture of different types of waste batteries. Collect waste lithium-ion batteries;

[0029] B) Break the casing of the lithium-ion battery by using a waste battery shell breaker, which includes a convex blade arranged in the axial die hole of the battery and a drive rod that pushes the battery to move in the axial die hole . The contents of the lithium-ion battery are collected after breaking the case, and the metal or plastic case is treated separately;

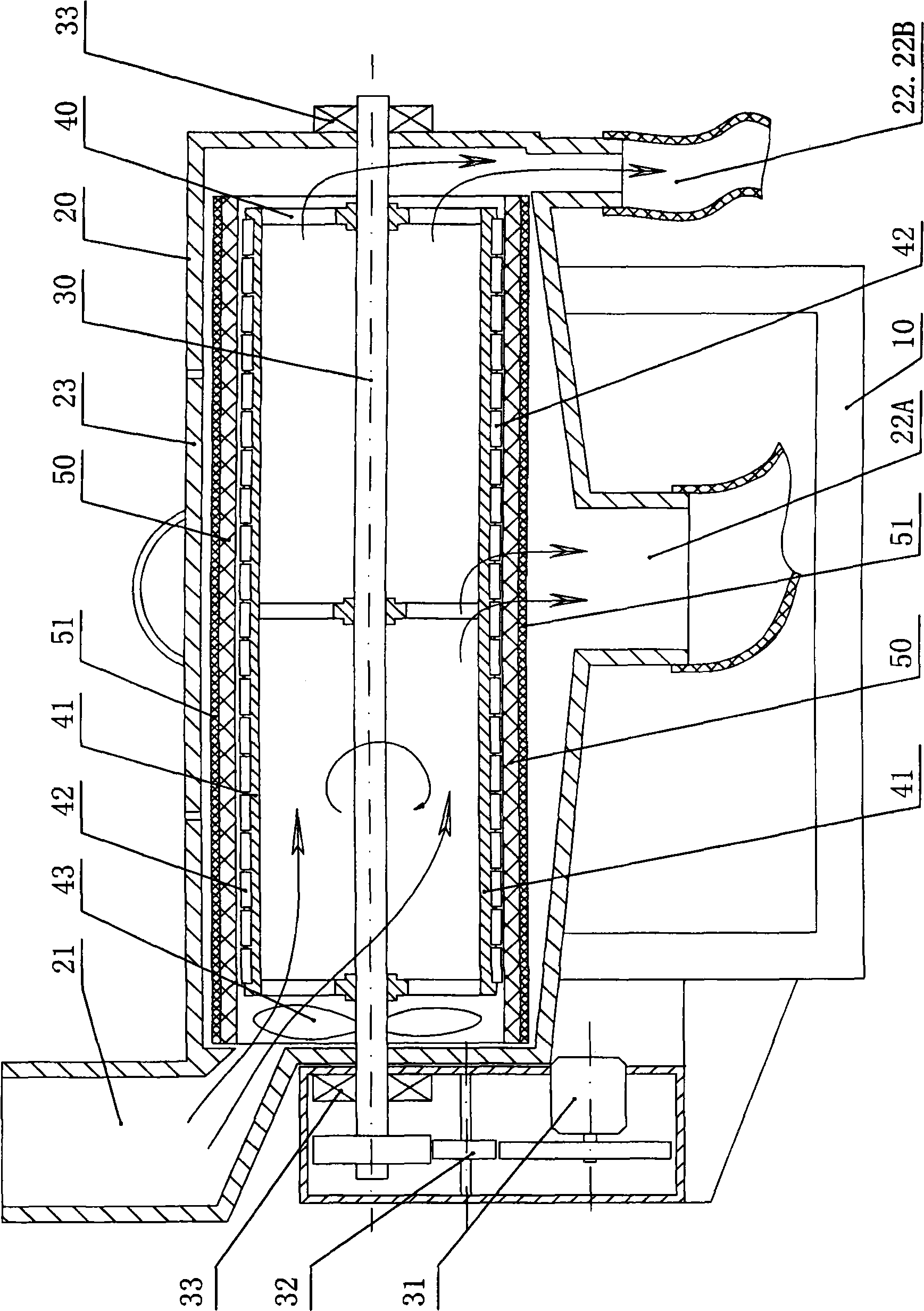

[0030] C) The collected lithium-ion battery contents are subjected to physical separation, and the physical separation adopts on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com