Carbon brush

A carbon brush and silicon carbide technology, which is applied in the manufacture of brushes, current collectors, electrical components, etc., can solve the problems of hindering the stable control of radio interference and insufficient control of radio interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

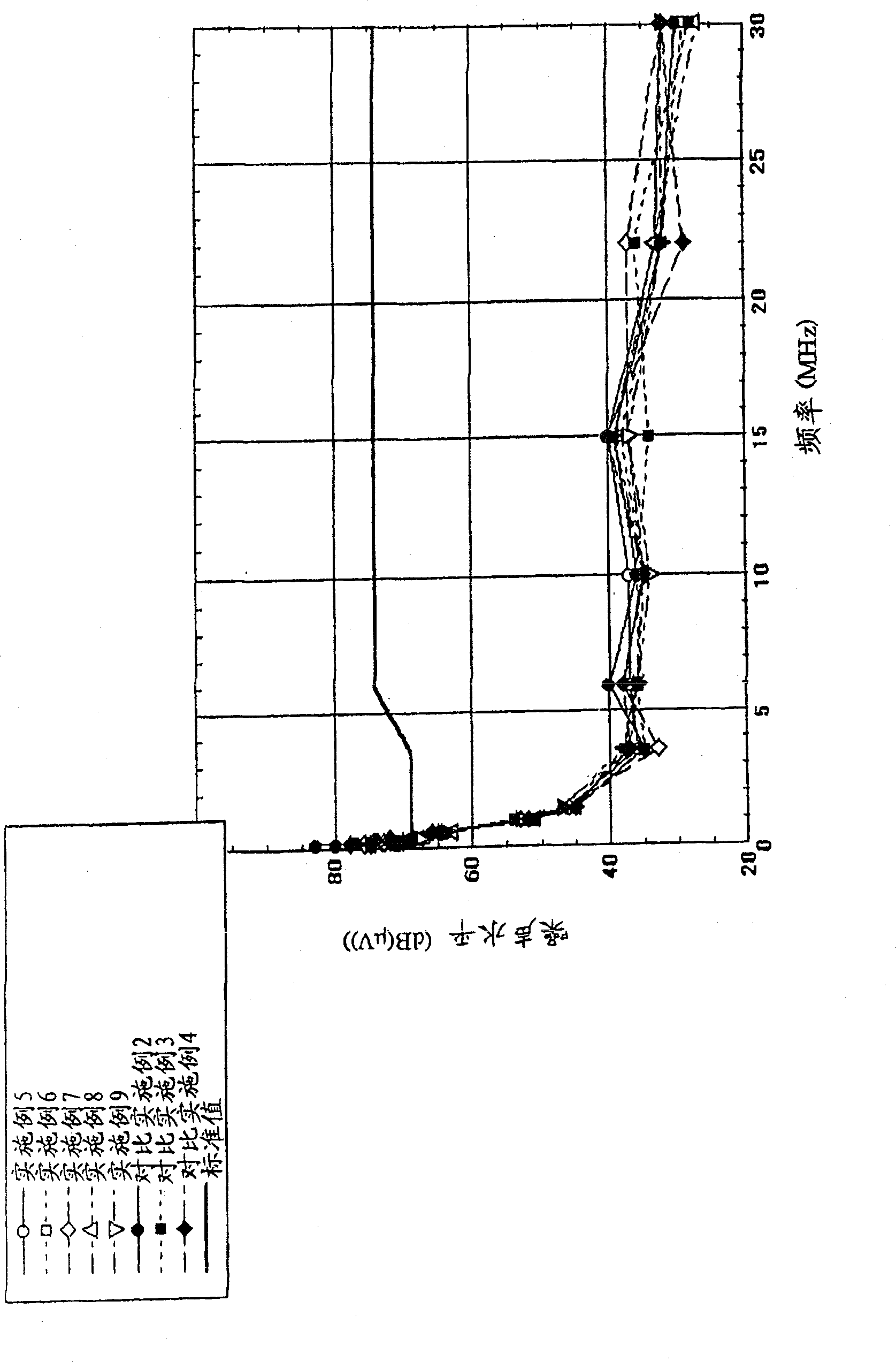

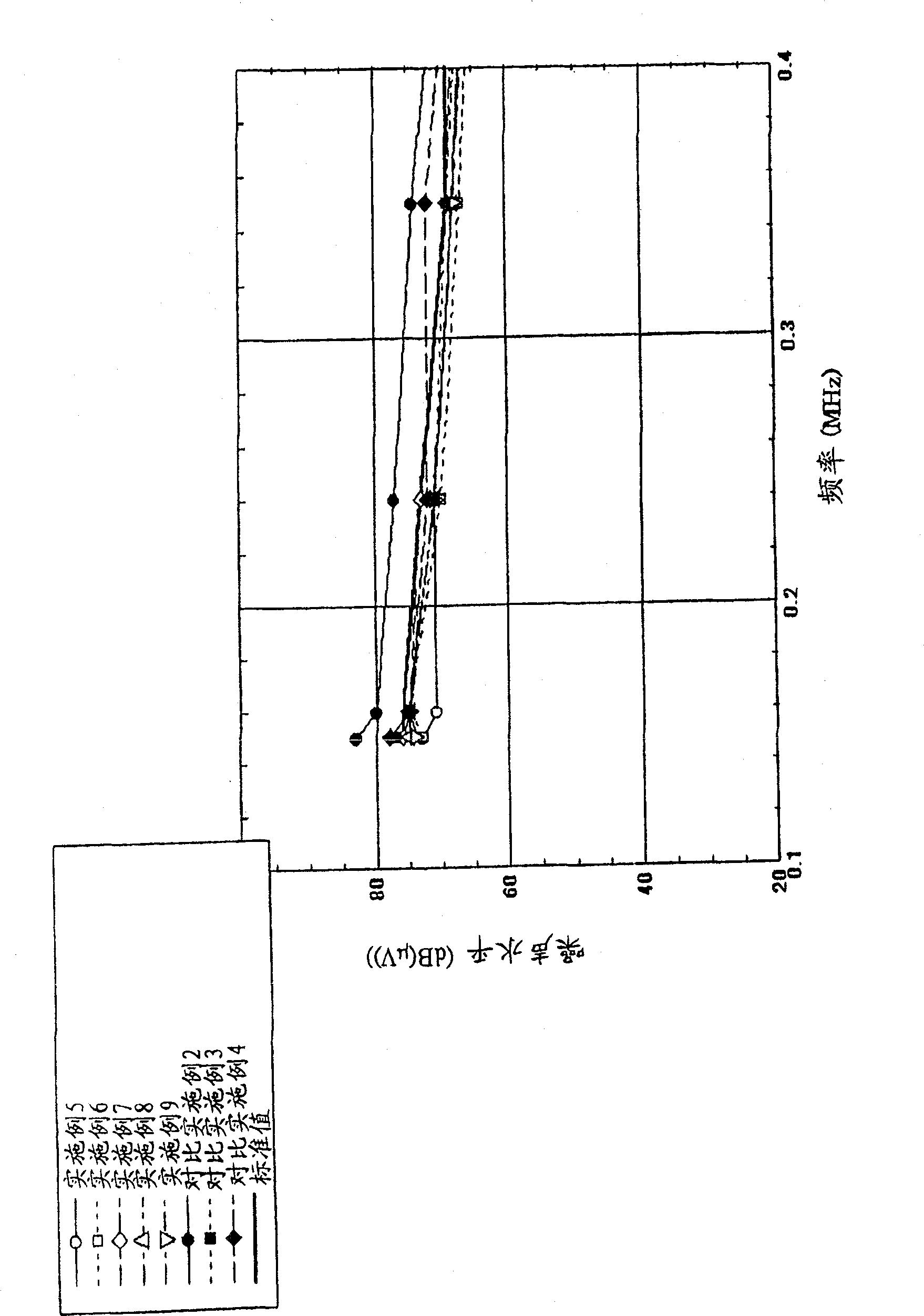

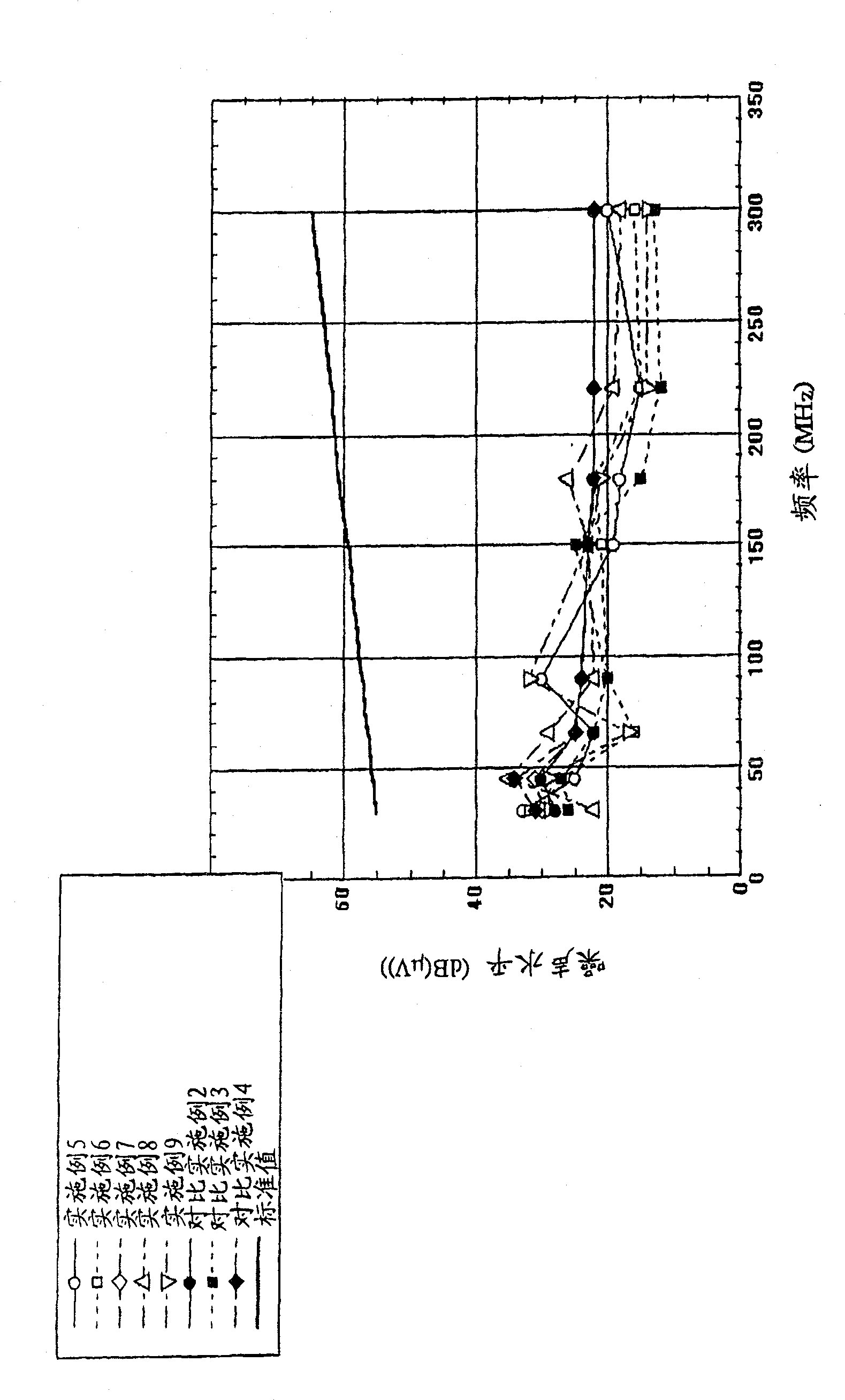

Examples

Embodiment 1

[0033] To 70 parts of a mixture of artificial graphite powder and natural graphite powder having an average particle size of 20 μm and an ash content of 1.0% or less, add 30 parts by mass of phenolic resin and 0.5 part of tungsten, and knead the mixture at 150°C for 1 hour . Thereafter, the mixture was ground to a particle size of 40 mesh or less and pressed into a size of 6×9×15 mm under a pressure of 100 MPa, and the resin was heat-treated at 700° C. to form a brush base. The dynamic viscosity of the brush base material measured at 40°C according to DIN51561 is 68 (mm 2 / s) of synthetic hydrocarbon-based oil and ester oil, and impregnated the brush substrate with oil to a total weight of 4.5% by weight.

Embodiment 2

[0035] A brush substrate was prepared by adding tin instead of tungsten in Example 1 at 0.5% by weight of the substrate. This brush base material was impregnated with oil so that the oil content was 3.8% by weight.

Embodiment 3

[0037] Brush substrates were prepared by adding zinc oxide (ZnO) up to 0.5% by weight of the substrate in place of the tungsten in Example 1. This brush base material was impregnated with oil so that the oil content was 3.7% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com