Inner inclined suspension type vibration avoiding system for shell and barrel integrated full automatic impeller washing machine

A pulsator washing machine, fully automatic technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of amplified amplitude, collision of dewatering barrels, and large size of washing machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

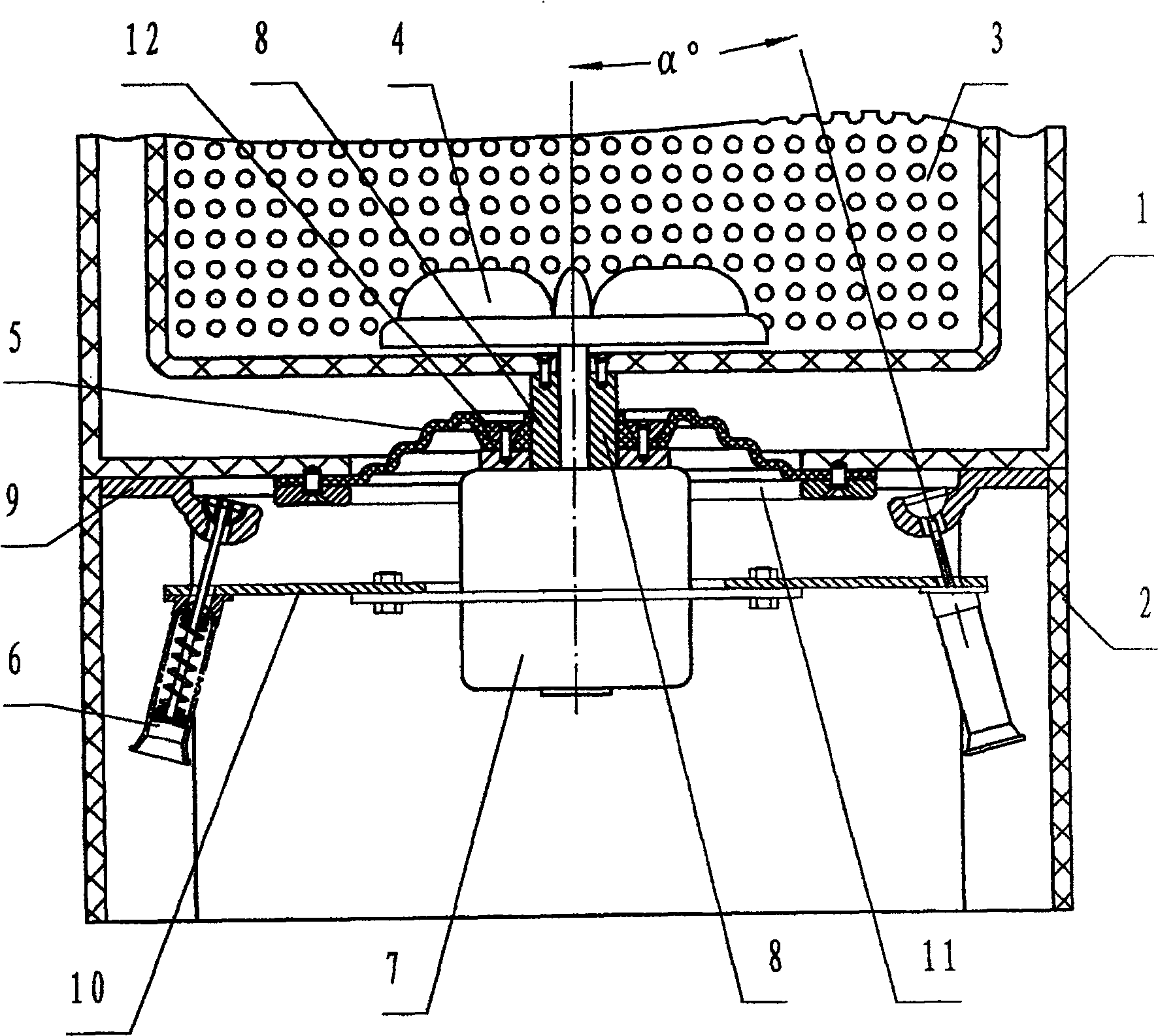

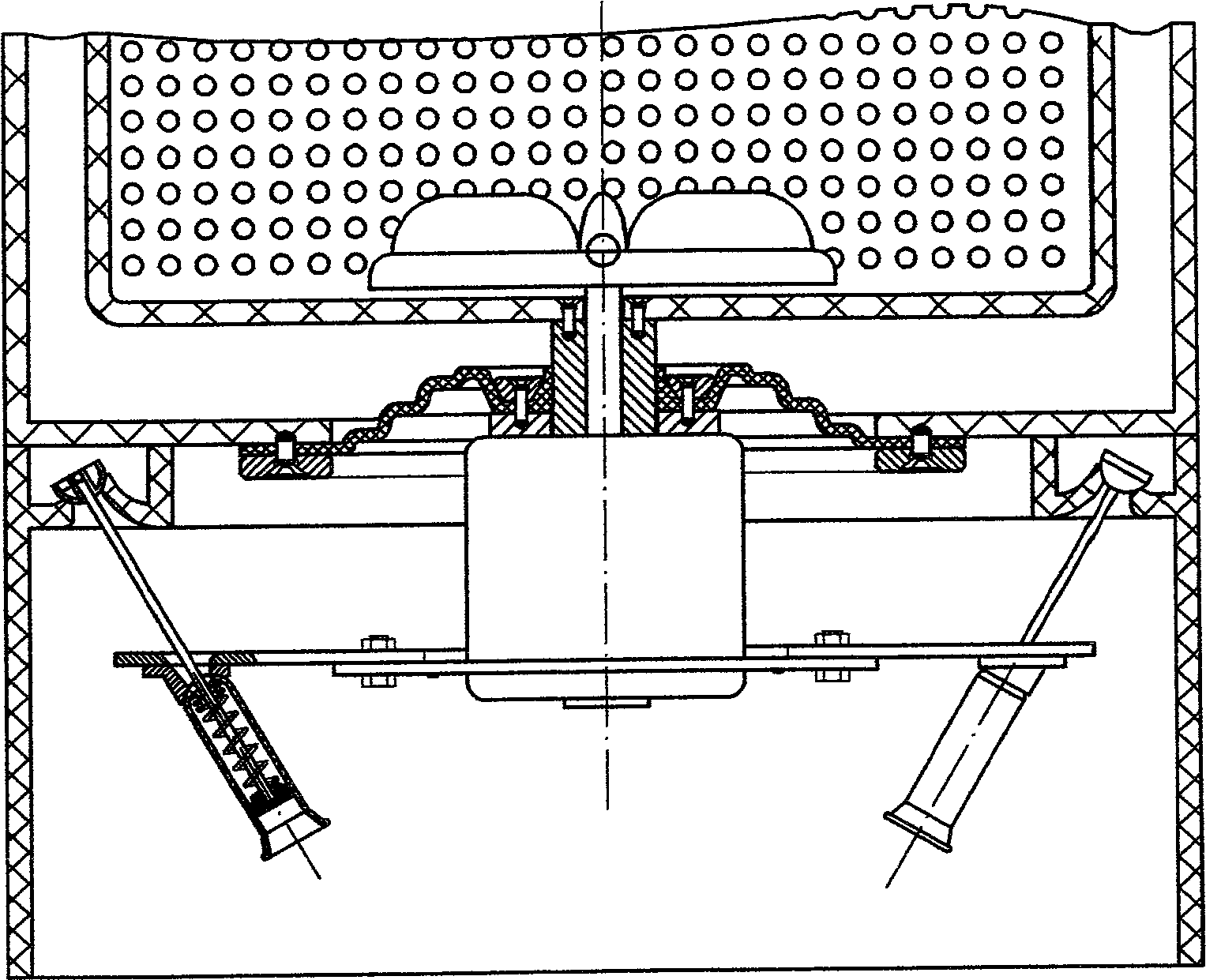

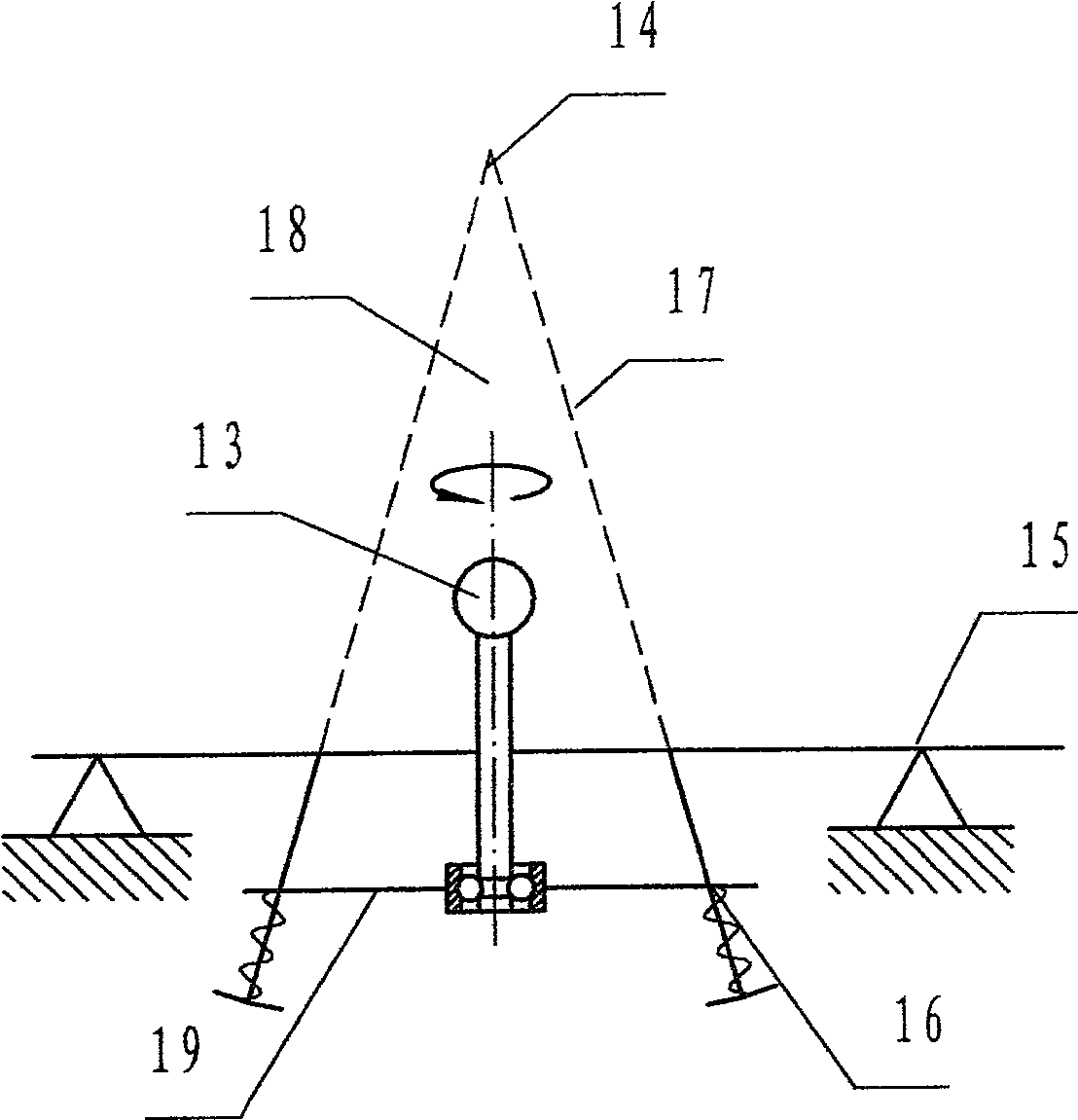

[0015] refer to figure 1 , a fully automatic pulsator washing machine with a shell and barrel in the present invention includes a shell and barrel 1, a base 2, a dehydration barrel 3, a pulsator 4, a rubber corrugated water sealing plate 5, and an elastic air resistance reducing system. Vibrator 6, electrical device 7, sleeve shaft 8, frame plate 9, machine base 10, large ring flange 11, small ring flange 12, wherein: the shell barrel 1 is made of plastic with a through hole in the center of the bottom The barrel-shaped water container with holes; the base 2 is a frame body made of plastic, and the four sides of the frame body are provided with tubular reinforcing ribs, and the top of the reinforcing ribs is provided with installation notches; the described dehydration bucket 3 is provided with many The bottom center of the small leak hole has a barrel-shaped drain with a through hole; the pulsator 4 is a disc with a fixed hole in the center of the paddle on the top; the rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com