Appartus for transporting metal working piece

A technology for transporting devices and metal workpieces, applied in furnace components, manufacturing tools, lighting and heating equipment, etc., can solve problems such as prolonged movement implementation time, movement interruption, etc., to achieve reliable force transmission and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

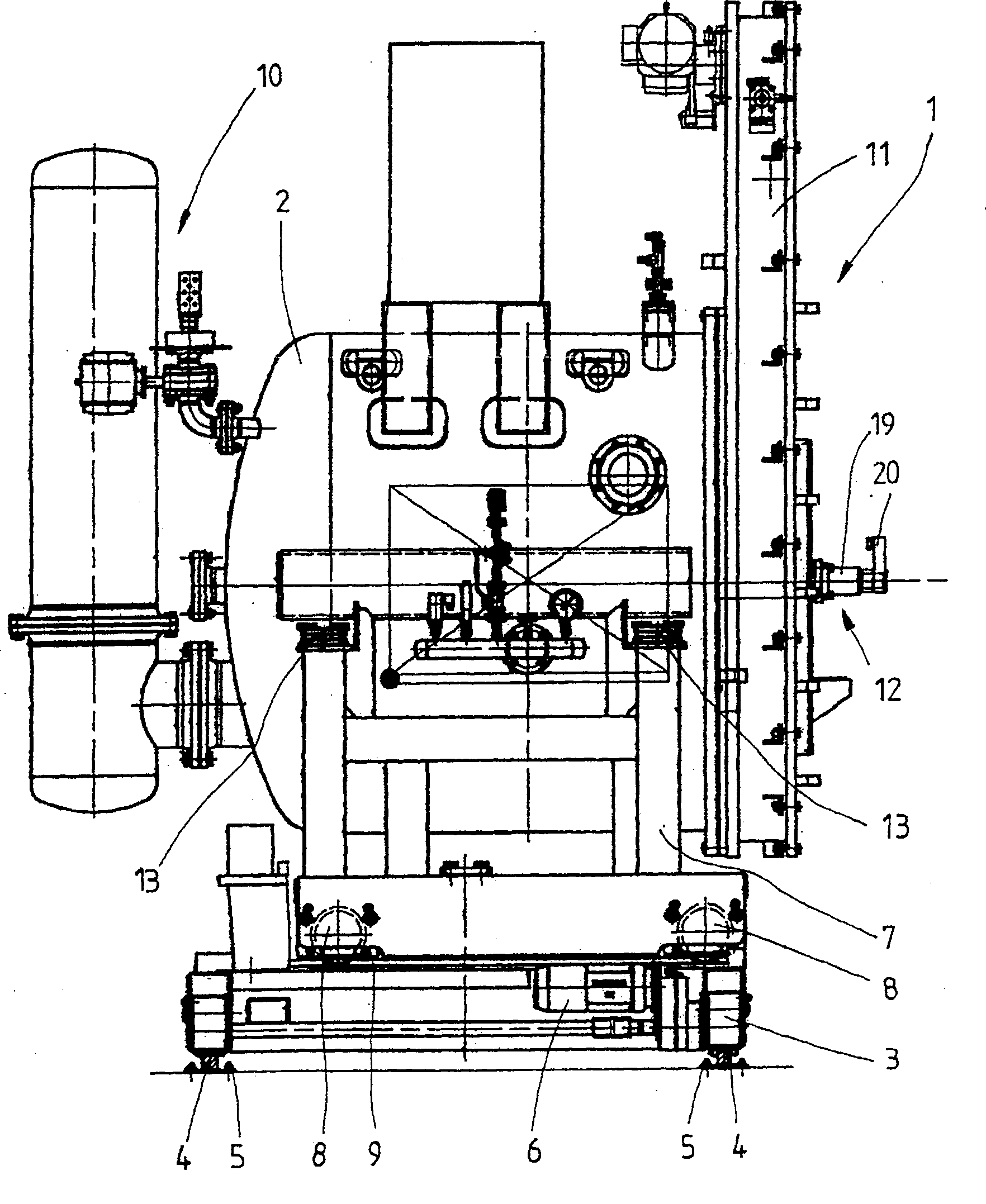

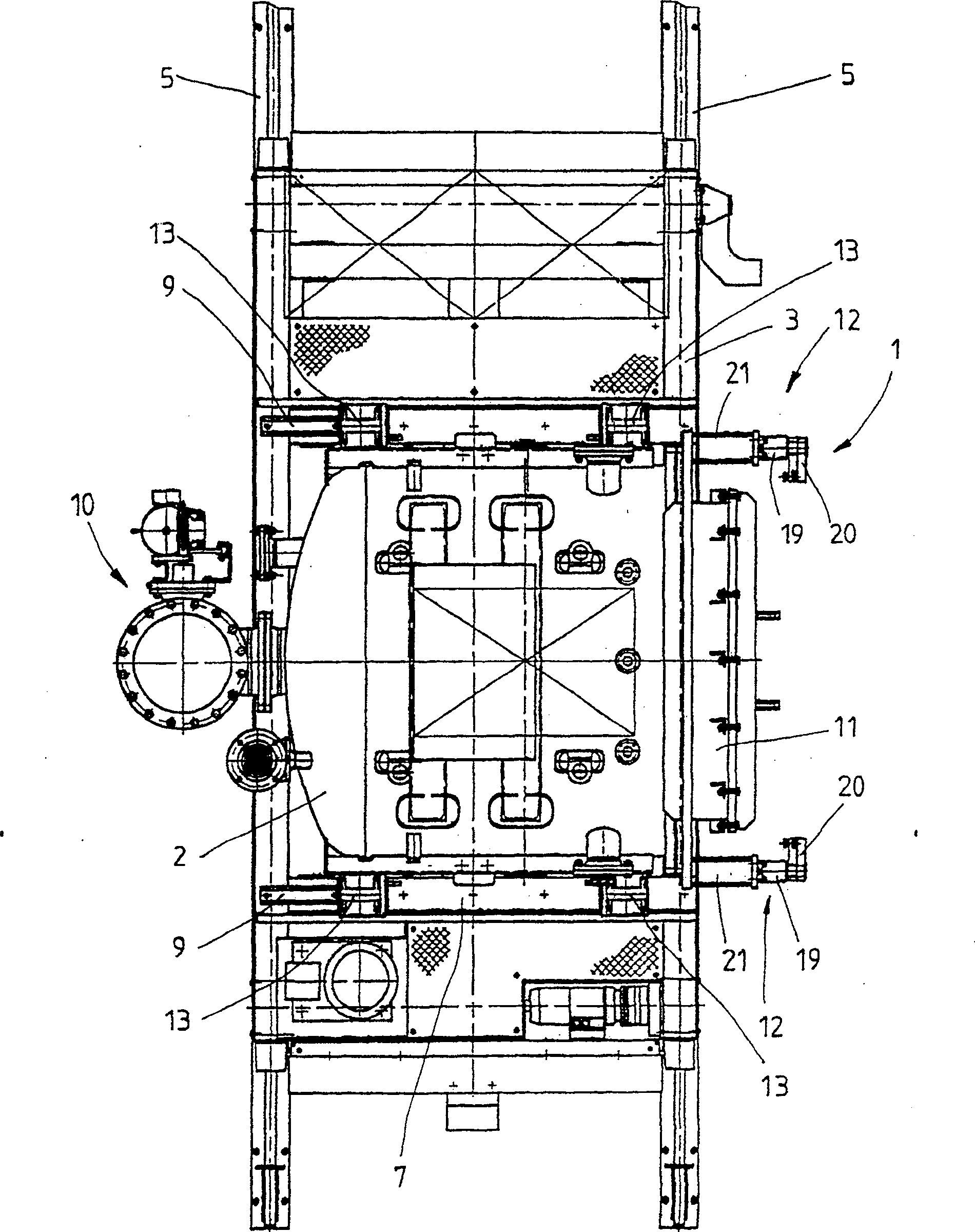

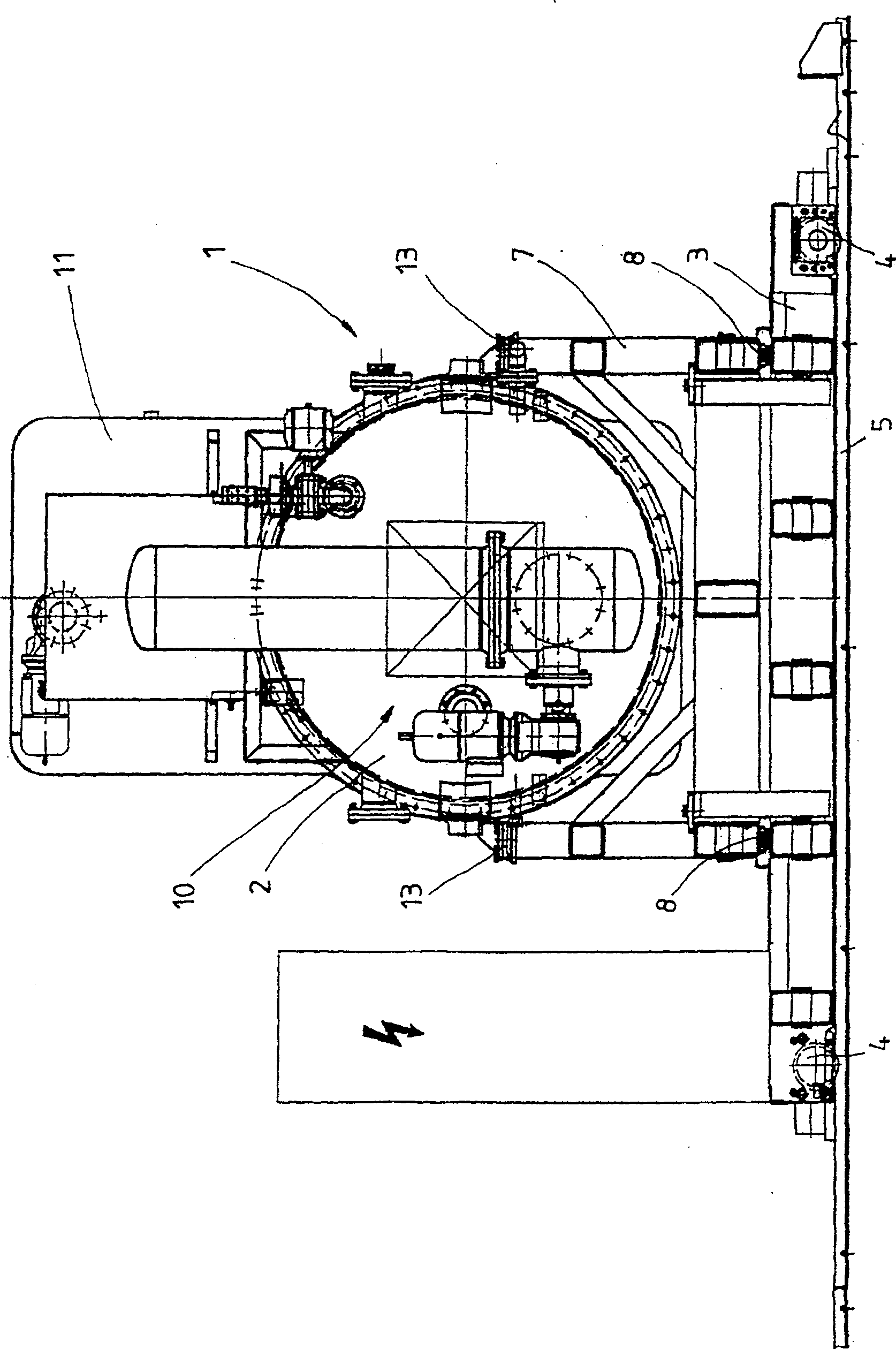

[0027] Figure 1-3 A device for transporting metal workpieces is shown, wherein the device 1 shown here has a transport device in the form of an externally insulated and vacuum-tight cylindrical transport chamber 2 . The transport chamber 2 is used for receiving and transporting workpieces, not shown in detail in the figure, which are arranged together in one batch.

[0028] Furthermore, the device 1 comprises a running gear 3, with which the transport chamber 2 can be moved horizontally. The chassis 3 preferably consists of a frame structure (not shown in detail) and is moved by means of corresponding wheels 4 on rails 5 formed for this purpose. The motor 6 arranged on the running gear 3 is used for driving. The transport device, which is formed as the transport chamber 2 , is supported by a frame 7 which is for its part movably arranged on this mechanism perpendicular to the direction of movement of the running gear 3 . For this purpose, the frame 7 has wheels 8 , by mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com